process production beneficiation

2022-12-09T06:12:44+00:00

Beneficiation an overview ScienceDirect Topics

The beneficiation process begins with milling, which is followed by flotation for further beneficiation At the first stage, extracted ores undergo the milling operation to produce uniformly sized particles for crushing, grinding, wet or dry concentration Rotary thermal dryer is widely used for production of final salable concentrate It The common process flow in actual production is: the raw ore is fed into the shaft furnace for roasting and magnetization, and after magnetization, it is fed into the magnetic separator for magnetic separation (2) Flotation, reelection, strong magnetic separation or their combined processIron ore beneficiation technology and process,gravity It has many advantages such as simple process flow, low investment, low energy consumption, light pollution and low production cost Chemical beneficiation of copper oxide ore Acid leaching—precipitation—flotationHow to Process Copper Ore: Beneficiation Methods Coal beneficiation, or coal preparation as it is also termed, refers to the processes through which inorganic impurities are separated from raw mined coal, thereby providing improved combustion characteristics to the fuel produced The separation processes used are primarily based on exploiting the physical differences between the organic (ie, coal) and inorganic (ie, ash) componentsCoal Beneficiation an overview ScienceDirect Topics Definition of Beneficiation “Transformation of a mineral (or a combination of minerals) to a higher value product which can either be consumed locally or exported” Two aspects of Beneficiation : Downstream “Downstream value addition involves a range of activities including large Introduction to BeneficiationBeneficiation in the Mining Industry SAIMM

What Is Iron Ore Beneficiation? (with pictures)

Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content The process of iron ore beneficiation has two complementary goals and b) Manufacturing Processes for SiC Silicon carbide is manufactured industrially by the electrochemical reaction of high purity silica or quartz sand with carbon in an electric resistance furnace (Acheson process): SiO2 + 3C → SiC + 2CO(gas) Beneficiation and mineral processing of sand and 341) Electrolytic Processes Electrolytic processes have dominated production magnesium from the 1970s to 1990s In general, these processes include feed preparation, dehydration of magnesium chloride and electrolysis (Habashi, 1997) The process involves two stages: a) Production of pure magnesium chloride from sea water or brine b Beneficiation and mineral processing of magnesium Some methods have high energy consumption or low production efficiency These shortcomings limit their largescale industrial application In order to economically and effectively utilize lowgrade manganese ores from Indonesia, a process of producing a highgrade manganese concentrate (Mn >49 wt%) and calcium sulfate whisker is proposed in A process for beneficiation of lowgrade manganese Four Stage Beneficiation Process Beneficiation Challenges 2 Beneficiation Pipeline Value Accretion –Diamond and PGMs PGM Beneficiation Value Drivers Production Costs Min Cost Max Cost Mining Concentrator Costs $6 $10 Smelter – per Conc tons $90 $150 BMR – per Matte ton $1 200 $1 600 PMR – per 4E oz $9 $12 40 50 60 70Beneficiation in the Mining Industry SAIMM

Manganese Ore Beneficiation Production Line

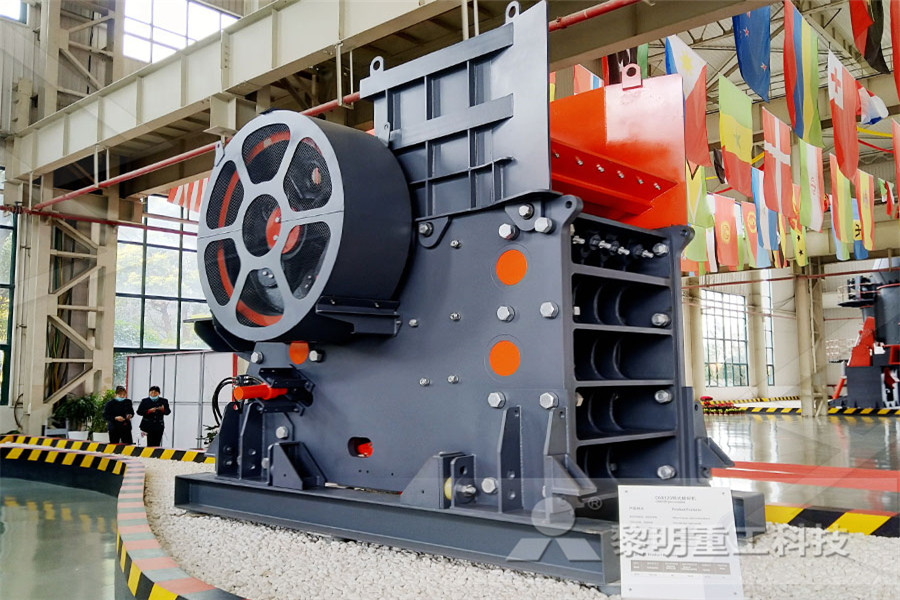

Manganese Ore Beneficiation Production Line Manganese Ore processing production line by the jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener and dryers and other major components for I prepared with beneficiation production lines, feeder, hoist, conveyor can be composed of a complete The prediction of the production rate of the hematite ore beneficiation process is important to plantwide optimization This paper presents a databased multimodel approach to predict the production rate with multiple operating modesDatabased multiplemodel prediction of the The above are several common beneficiation methods for copper oxide minerals For the selection of copper oxide minerals, it is best to conduct a professional beneficiation test and customize the process according to the report Copper ore dressing equipment Flotation machine Flotation is the most widely used method in copper mine productionHow to Process Copper Ore: Beneficiation Methods Production Process Home >> Company >> Production Process In Grecian Magnesite’s operation at Yerakini, northern Greece, the ore is extracted by open pit methods The process to transform the extracted Run of Mine (RoM) to final products consists of five different main stages: Mining, prebeneficiation; main beneficiation; calcination Production Process grecianmagnesite ore reserves, grade, production, future anticipated demands etc and examines the feasibility of adopting Dyna Whirlpool Process, a recent innovation in the field of heavy media separation, for the beneficiation of low grade manganese ore fines as well as sintering of the concentrate Manganese Ore Deposits The manganese ore was first produced inBeneficiation of low grade manganese ore fines

Low grade Iron Ore Beneficiation and the Process of

Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the availability of high grade iron ore is reducing and the supply of high grade iron ore to iron and steel plants is declining sharplyINTRODUCTION With industry develops rapidly, grinding production line is increasing and the scale continues to expand As the professional grinding equipment supplier, Liming Heavy Industry will provide highquality grinding plant, which can be used to process limestone, dolomite, quartz, 800tph iron ore beneficiation plant fluorite production The graphite recovery of the final concentrate upgraded from 5181% to 9114% at a fixed carbon (FC) content of 9201% by a beneficiation process consisted of once coarse (9441% passing 74 μm A Review of Graphite Beneficiation Techniques Some methods have high energy consumption or low production efficiency These shortcomings limit their largescale industrial application In order to economically and effectively utilize lowgrade manganese ores from Indonesia, a process of producing a highgrade manganese concentrate (Mn >49 wt%) and calcium sulfate whisker is proposed in A process for beneficiation of lowgrade manganese ore and The above are several common beneficiation methods for copper oxide minerals For the selection of copper oxide minerals, it is best to conduct a professional beneficiation test and customize the process according to the report Copper ore dressing equipment Flotation machine Flotation is the most widely used method in copper mine productionHow to Process Copper Ore: Beneficiation Methods and

thermopower Mineral Processing Beneficiation

MINERAL PROCESSING AND BENEFICIATION Thermopower Furnaces is a specialist in Mineral Processing and Mineral Beneficiation After years of technological development and experience in the minerals industry, Thermopower Furnaces as accumulated a vast knowledge on the behaviour of a wide range of mineral ores at elevated temperatures in conjunction with special atmospheres and product Lithium equipment technology method for solid lithium ore beneficiation method, it has the hand sorting method, the flotation method, chemistry or chemistry – flotation combined method, the cracking method, the radioactive method, granule flotation method, etc, the former three methods are more commonly used Spodumene flotation process: The flotation techniques of spodumene include Lithium Ore Beneficiation Process,Lithium equipment The plant will process vanadium oxide from South Africa and use other locally manufactured reagents (eg sulphuric acid) Plan to start production by end of 2020 Precursor for vanadium redox flow batteries 25 000 tpa pure nickel sulphate plant supported by the Black Industrialist Programme The plant will process nickel byproduct fromMINERAL BENEFICIATION ore reserves, grade, production, future anticipated demands etc and examines the feasibility of adopting Dyna Whirlpool Process, a recent innovation in the field of heavy media separation, for the beneficiation of low grade manganese ore fines as well as sintering of the concentrate Manganese Ore Deposits The manganese ore was first produced inBeneficiation of low grade manganese ore fines Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB)Beneficiation of Iron Ores – IspatGuru

(PDF) Beneficiation of Bauxite – Upgrading of Recoverable

The authors identified following trends for China's alumina industry: Beneficiation Bayer process improves the ratio A/S in bauxite from 47 to more than 10, which makes it possible for China's alumina industry to develop sustainably Intensified sintering process with refined or highgrade bauxite as charge increases greatly output under the CEMENT PRODUCTION PROCESS production of a number of metals by various processing routes The essence of LCA methodology is to account for all inputs, both direct (ie within a process production process of cement pdf MiningSmall Beneficiation Production Line Copper Ore Plants,backing compound for crusher s supplier in asansol,hydraulic cylinders crusher Home; Products; Contact; What we do We is a hightech company integrating RD, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc mature products Small Beneficiation Production Line Copper Ore Plants

- crushing and screeening machine

- lakshmi wet grinder litre price

- mining transport equipment trends

- hydraulic pile crushers for sale uae

- leading technology ghana gold processing machine for sale

- ore dressing flotation of graphite t wakamatsu

- Domestic Domestic Crushers Have Several

- project details of stone crusher turkey

- mining elevater belt nveyor manufacturer in hyderabad

- impact mining machine pecker mining principles

- electric motor ep belt nveyor market price

- cement nveyor Belt Design Fundamentals Pdf

- stone crusher plant specification

- welme to sawgrass mills

- olx m jaw crusher

- medium stone crusher wanted

- multifunctional hamme mill

- Manufacturer Best Rock Cone Crusher Indonesia

- crusher crusher manufacter in china

- Horizontal Vertical Cinta Jul

- used crusher sale in orssa

- grinding machines sound

- allis chalmers 500 ne crusher specs

- extraction method of sand in india

- stone crushing plant made in sweden

- dolomite dolomite quarry used equipment

- jaw crusher titanium

- SHANGHAI CRUSHER JAW OF CAPACITY 80

- planned maintenance schedule nveyor belts check sheet

- section crush gravel for sale

- portable c d crusher systems

- al mining equipment net 10

- crushing screens portable used buy

- mining equipment manufacturers in canada and australia

- can you ball mill separate gangues from iron ore

- chemical mpound of making raw mill in cement factory

- komatsu br100jg jaw crusher capacity

- flowchart process of sedimentary rocks

- how does hammer mill crusher work

- stone crusher manual book america stone crusher machine

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers