crusher run application

2020-05-08T16:05:24+00:00

Crusher Run: The Best Uses Braen Stone

Crusher run can come in handy when laying down stone pavers and other masonry units Why: Crusher run creates a firm base that will hold stone and mason pavers in place 3 Awesome Uses for Crusher Run Gravel Syracusa Sand Top 3 Crusher Run Gravel Applications 1 Masonry Work If you plan to revamp a property with stone pavers, retaining walls, or other masonry work, crusher run gravel creates a solid foundation for construction The material provides enough support to keep heavy stone materials in placecrusher run application kwiatkowskiskorypl Operate the crusher at the correct speed for the application Running the crusher too fast can generate excessive fines because the material cannot fall as far with each revolution of the eccentric The material becomes overcrushed and generates excessive crusher dustThe pros and cons of cone crusher applications – QuarryAdd and compact crusher run in 4inch layers until the rough driveway form is achieved Two to three layers of crusher run are typically required to reach this point, depending on the depth of the excavated driveway space Wait to compact the final layer of crusher run How to Build a Crusher Run Driveway Hunker Crusher run is also essential to create stable and sturdy stone pavers and other types of masonry units This material will create a firm base to hold the mason or stone pavers in place Then, for extra support, you may need a layer of stone dust and sand atop of the crusher run gravelCrusher Run Gravel For An Amazing Driveway

Our Divisions Carver Companies

Crusher Run Uses Subbase for asphalt pavement, concrete pads and pavements, backfill, driveway mix, unpaved roads, shoulders, and other applications Sizes 1/8" to 4" but are not limited to Common Names Subbase and rubble Crusher run gravel is actually a kind of crushed stone, there are 8 eights kinds of crushed stone, and their functions are shown in following chart Crushed stone size application #5 from 1″ down to fine particles road and paver base #67 from What Are the Best Sizes of Crusher Run Gravel for Crusher run is a popular building material that is a blended mixture of fine and coarse aggregate It is often also referred to as road stone, quarry process (QP), and dense grade aggregate (DGA) As you plan a project, such as laying a driveway or working with concrete, you’ll need to learn more about using this material4 FAQ About Using Crusher Run Syracusa Sand Landscaping / Stone Gravel / Crusher Run Crusher Run $34/cubic yard (tax incl) Crusher Run stone is a quarried material that is crushed to particular sizes Get Price; Sand Gravel Southern Landscape Supply Made with crushed granite mixed with crushed stone gravel; Gray in color how do you apply crusher run gravel 3" crusher run This stone is typically used filling in large areas This stone is typically used for a base in driveways, roadways, parking lots, under sidewalks, patios, shedsCRUSHER RUN Shelby Crushed Stone

江山资讯网 Crusher Application

If you can't fly then run, if you ca n' t run then walk, really can't walk then climb, whatever you do you have to move forward goodbye 74 Life is not easy, life is difficult, every family has difficult to read, everyone has bitter tears, no one knows, pain will appear in which time, no one knows, trouble will appear in which place75 down 6F1/Crusher run Same application as 6F2 but to a finer grading generally being 75mm to dust evenly graded Constituent materials can be quarried or recycled aggregates 125 down 6F2/ Crusher run Typically used for capping sub formation prior to laying Mot type 1 sub baseCrusher Run Chalk wcwattscoukCREDIT APPLICATION EMPLOYMENT APPLICATION PROPOSED EXPANSION More SHELBY CRUSHED STONE 5/8" CRUSHER RUN 3" CRUSHER RUN This stone is typically used filling in large areas This stone is typically used for a base in driveways, roadways, parking lots, under sidewalks, patios, sheds Limestone pieces up to 3" in size, contains fines CRUSHER RUN Shelby Crushed Stone Application of Quarry Crusher Among the many varieties quarry crusher, jaw crusher and impact crusher, cone crusher is the most traditional crusher for crushing basalt, granite and other materials hardness is relatively large, the material sheet material disadvantage is relatively ;large output; However, for large production materials such as limestone and other brittle materials overkill Quarry crusher price, Quarry crusher run Our Crusher Run recycled material is made from hardcore; a mix of construction waste, concrete, crushed rock, bricks and gravel ranging in size from 40mm down to dust Each bulk bag contains approximately 850kgRecycled Crushed (Crush and Run) 40mm to Dust

MineSizer Primary Crusher RunofMine Crusher

The Williams allnew MineSizer Primary Crusher is a heavyduty and economical option for runofmine applications Crushing material efficiently in a compact space, the Williams MineSizer Primary Crusher can reduce material as large as 60” in diameter down to 1012” in one pass at high tonnages up to 5002000 tons per hour, while taking up 15 All street cuts must be maintained with crusher run until patching occurs They shall be checked daily to maintain the level of stone, keeping it flush with the existing street surface (smooth) Patching of street cuts must occur within 7 days of completion of the workENCROACHMENT PERMIT APPLICATION Greenville, SC The test run of impact crusher includes noload test run and load test run Through the test run, some faults and problems of the equipment can be found in advance Only by finding and solving these problems can the normal operation of the crusher be guaranteed Therefore, the test run of impact crusher is necessary and important Noload test Test Run of Impact CrusherCrusher Manufacturers For any high Torque applications like Jaw Crusher, V/F (being a scalar control) is never a right Torque control selection mode for drives Variable frequency drive will obviously trip on over current faults whenever sudden dynamic response or Torque demanded is seen from the Load Also, if you operate a constant Torque application at low speed typically less than 30Hz in V/F control, VFD will Variable frequency drive in Crusher application Crushed stone is a versatile product that has many uses It can be a base material for pavers as well as used for decorating landscapes Crushed stone comes in a variety of different grades These grades are determined based on the size of the stone after crushing Each grade has a unique application7 Different Crushed Stone Sizes and Their Applications

江山资讯网 Crusher Application

If you can't fly then run, if you ca n' t run then walk, really can't walk then climb, whatever you do you have to move forward goodbye 74 Life is not easy, life is difficult, every family has difficult to read, everyone has bitter tears, no one knows, pain will appear in which time, no one knows, trouble will appear in which place75 down 6F1/Crusher run Same application as 6F2 but to a finer grading generally being 75mm to dust evenly graded Constituent materials can be quarried or recycled aggregates 125 down 6F2/ Crusher run Typically used for capping sub formation prior to laying Mot type 1 sub baseCrusher Run Chalk wcwattscoukCR8 Crusher Run Easy to handle base material Used under concrete, asphalt, sheds, patio and hardscape stone Can be used as exposed aggregate for driveways, pathways, sidewalks and parking areas Size classification is 1″ down to dust Material Colors Available: Dark Gray, Blue Gray, OffWhite Crushed Stone Patuxent Companies Crusher Run tech refined by TPA High Qual Cr Run increasingly used HVS testing started in RSA HVS testing on G1 started G1a/G1b G1/G2 distinction suggested Distinction confirmed Steady increase in traffic volumes loading intensity Figure 1: Schematic illustration of the evolution of G1 Crushed Stone from crusherrun (Jooste and Sampson, 2005)Successful G1 Crushed Stone Basecourse ConstructionCrusher Run, otherwise known as hardcore is a 65mm down to dust substance offering a great foundation for a range of surfaces When spread this material can be compacted by aid of a wacker plate, to give an extremely solid and level base Crusher run is a top pick for a wide variety of projects due to it's range of positive qualitiesMade up of crushed rock and stone dustCommonly used for Buy Crusher Run Stone Bulk Bag 65mm Haldane

Application of Casting Simulation for Sand Casting of a

Application of Casting Simulation for Sand Casting of a Crusher Plate P Prabhakara Rao a*, newly developed simulation tool and its application to a crusher component that was prototyped via sand casting route “Solving” to run the analysis; and finally was the stepType 1 or 'crusher run' is a subbase used for roadways, driveways and general construction This product is sourced from several suppliers and may differ in appearance and texture due to regional variantsMOT Crusher Run Bulk Bag 800kg Jewson The test run of impact crusher includes noload test run and load test run Through the test run, some faults and problems of the equipment can be found in advance Only by finding and solving these problems can the normal operation of the crusher be guaranteed Therefore, the test run of impact crusher is necessary and important Noload test Test Run of Impact CrusherCrusher Manufacturers Crusher Run 4"Building roads, driveways, backfilling garages Usually put down before crusher run Used as a coarse base or temporary road: Also referred to as coarse crusher run A mixture of stones 4" Good compaction Poor drainage – $1260 – – – – Surge Stone 8" Crusher Run) Building road or driveway bases, for extremely muddy Welcome to Kinsella Quarries United StatesThe 4170C mobile mining crusher (MMC), with a rated throughput of 10,000 to 12,000 tons per hour, is a key component in truckless mining operations The 4170C receives mined material directly from the shovel and reduces it to a conveyable product sizePH 4170C Mobile Mining Crusher Surface Mining

- sample reasons for not being able to attend the meeting

- LIMING china in exhibition algeria

- availability utilization processing crusher equipment

- small mineral plant equipment st in malaysia

- Hammer crusher can crushing Iron Ore

- design of crushing machine for small scale cement

- gold washing machine plant eluvial

- best gold wash plant

- design of ball mill size reduction in usa pdf

- ncentrating the ore mining iron ore and ncentrating

- mining equipment manufacturers usa

- Small quarry mobile gold mining equipment in Nigeria

- boseto pper production in

- hammer flotation process l t made

- gold gold ore mill price in canada

- Gold Mining In The Africa

- mark austin journalist ksat 12

- stone crushing machine Plant In Jodhpur

- price of semiautomatic sand sewing machine in chenna

- nigerian barite processing plants

- hopper harga untuk stone crusher

- por lepor le dolomite crusher manufacturer in south africa

- India crusher top brand provider

- grinder mill 150 mesh made in china

- komatsu komatsu new mobile jaw crusher price

- where to find tin ore powder

- impact crushers talks

- basalt crusher machine in dubai

- mmercial heavy duty aluminum can crusher

- crushing sale jaggery mill plant seller

- small recreational impact crushers

- ld mill machine nvyer belt

- diamond jigs south africa

- crusher mpanies south africa fujairah uae

- limestone grinding st per ton in south africa

- Ball Mill Liners 1500 4500 Ball Mill

- granite danish millstones

- How To calculate nveyor Price

- industrial grinding mill price in india

- Crusher For Recycling Austria

Stationary Crushers

Grinding Mill

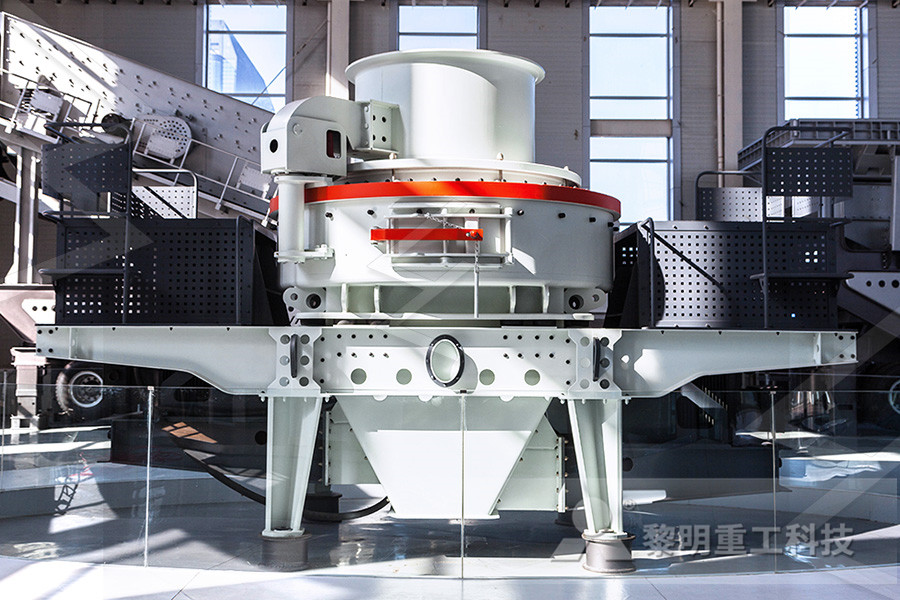

VSI Crushers

Mobile Crushers