ferrous mining ncentrate process processing plant

2022-06-01T18:06:01+00:00

SolutionMineral Processing Plant

FERROUS METAL BENEFICIATION PROCESS Xinhai can provide the whole and onestop mineral processing plant service for clients, solving all the mine construction, operation, management problems, devoting to provide modern, highefficiency, and energysaving mine roject construction and operation solution for clients away from worriesBeneficiation Of Ironn Ore Production Of Ferrous S Coal Mining Processing Plant In Nigeria This Coal Mining Project Is An Open Pit Mine Located In Nigeria, Announced By Mining Company Western Goldfields That It Has Discovered 62,400,000 Tonnes Of Proven Reserves Of Coal Deposits Worth US$12 Billion Which Could Be Used For The Generation Of Electric PowerBeneficiation Of Ironn Ore Production Of Ferrous SGold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lowers the gold mining operation cost and increases gold recovery rate to 99%, which is the first choice of modern gold mining and gold beneficiation plantProduction Line, Mineral Processing, Concentration of Xinhuan Nonferrous Metal Smelting Plant In January, 2008, Huachang Antimony Industry invested to Xinhua Nonferrous Metal Smelting Plant and took charge of purchasing raw materials for the plant Established in March, 1985, the former name of Xinhuan Nonferrous Metal Smelting Plant is Lei yang Lead Zinc Smelting PlantXinhuan Nonferrous Metal Smelting PlantHuachang iron ore concentrate process – CGM mining application high gradient magnetic separator, iron sand concentrate machine for ferrous manganese ore June 25, 2012, Comments Off iron sand of machines – Mineral Processing Plant Iron sand concentrate machine,Iron sand making machine machine processing iron sand consetrat Mining

Modular concept // REMEX Processing // Metal

The main processing plant for incinerator bottom ash serves as the base module Treatment includes the use of different sieving techniques, magnet and eddy current separators as well as a wind sifter At the end of this process, we end up with three fractions, ie ferrous metals, nonferrous metals and the remaining mineral fractionDownload Citation SilverContaining Concentrate Processing The goal of the research was to melt the silvercontaining concentrate from the Dukatsk deposit (Magadansk region) in a reverberatory SilverContaining Concentrate Processing Common copper ore concentrate equipment of copper processing plant is a traditional thickener, efficient deep cone thickener, inclined plate thickener; common filter used in a copper mining process plant are disc vacuum filter and a ceramic filter Xinhai company has a variety of thickeners and filters for customersMining Process For Copper – Series II Xinhai The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics The Manganese Ore Processing 911 Metallurgist This gold concentrates process is similar to most of the concentrate of ore, so the use of gold concentrator is no difference In the gold mining process, need hydraulic drill rig trucks, loaders and crushers and other machinery According to mined gold ore grade, the followup gold concentrate process to be determinedDo you know the gold concentrator used in gold

process for processing chrome at a concentrator plant

Previous Projects Metallicon Process Consulting Optimisation PGM concentrators and implement "Two Concentrate" Process Chrome from UG2 tailings spiral plant process design input for a range of installations including pebble crushing, chrome and PGM processing plants Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota Creating steel from lowgrade iron ore requires a long process of mining, crushing,Iron Ore Processing The Welding Handbook Ore flotation process plant [ Production Capacity ] 1300tph [ Application: ] The flotation separation process is mainly applied to separate copper, zinc, lead, nickel, gold, iron and other nonferrous metals,It is also able to process ferrous metals and precious metalOre flotation process plant Baichy JXSC Mine Machinery Factory provides coltan mining process Jig Concentrators for more than 30 years, focus on the tantalite, tantalum, columbite, niobium and other rare earth ore metals and minerals like gold, diamond, chrome, tin, tungsten and silica sand processing plants Jig Concentrators for Coltan Mining Process JXSC has established a number of successful coltan mining projects for Jig Concentrators for Coltan Mining Process JXSC Coal mining processing plant in Nigeria This coal mining project is an open pit mine located in Nigeria, announced by mining company Western Goldfields that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US$12 billion which could be used for the generation of electric powerrefining of ferrous metal ore china

Xinhuan Nonferrous Metal Smelting PlantHuachang

Xinhuan Nonferrous Metal Smelting Plant In January, 2008, Huachang Antimony Industry invested to Xinhua Nonferrous Metal Smelting Plant and took charge of purchasing raw materials for the plant Established in March, 1985, the former name of Xinhuan Nonferrous Metal Smelting Plant is Lei yang Lead Zinc Smelting Plant Installed at Vale's Ferrous Technology Center (CTF), in Nova Lima, (Minas Gerais), the pilot plant is the second to start operating Between 2015 and 2017, a unit operated at the Fábrica's mine also in Minas Gerais The good results were fundamental for Vale to see the potential of the FDMSVale inaugurates pilot plant that allows for more Lead Zinc Mining Process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read more Zinc is an important nonferrous metal raw material, it is second only to copper and aluminum in the consumption of nonferrous metals It has good calendering, wear resistance and corrosion Lead Zinc Mining Process Equipment Flow Cases Prominer can provide the solution for different mineral processing plant’s dewatering purpose or the removal of water from solid materials or soil via wet classification, centrifugation or filtration Our dewatering system is widely applied in slurry density adjustment, desliming, concentrate and tailing dewatering processDewatering System For Minerals Processing This plant is associated with the lead and tin smelter/refinery complexes located at Hosokura and Ikuno respectively Fig 1 depicts the treatment of residues at ’s Akita zinc smelter and refinery to recover cadmium byproduct and concentrate the indium fraction for subsequent recovery (, 1984) At Akita, the Processing of indium: a review ScienceDirect

M i N M E T – Mining Processing Metallurgy

STEEL FERROUS METALS AustraliaOceania Ferrous Metals First Quantum sells 30% of Ravensthorpe Nickel to POSCO Mammoet to move 7000t mining plant in Mozambique September 7, 2020 September 6, 2020 admin 0 products and services related to mining processing and metallurgical sectors Whether it’s processing high volumes of iron ore, or removing micronsized ferrous or paramagnetic contaminants from valuable minerals, Eriez offers a complete range of continuous and batch magnetic solutions for wet processing In hard rock mining, specialized magnetic equipment improves ball mill efficiencies by removingMining Minerals Processing EriezPGM Ore Processing at Impala's UG2 Concentrator SGS coming from the increased processing of ore through the UG2 plant, located 20 km NW of Rustenburg was coarse limiting the risk of chrome entrainment into the final concentrate, but also process for processing chrome at a concentrator plant SF Flotation Plant is widely used for roughing, concentrating and counterflotation of nonferrous metal that includes gold, copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic mineral Working Principle of the flotation plant The impeller is driven by Vbelts, which can bring the centrifugal effect to form the negative pressureFlotation Plant in Metallurgy JXSC MachineXinhuan Nonferrous Metal Smelting Plant In January, 2008, Huachang Antimony Industry invested to Xinhua Nonferrous Metal Smelting Plant and took charge of purchasing raw materials for the plant Established in March, 1985, the former name of Xinhuan Nonferrous Metal Smelting Plant is Lei yang Lead Zinc Smelting PlantXinhuan Nonferrous Metal Smelting PlantHuachang

Jig Concentrators for Coltan Mining Process JXSC

JXSC Mine Machinery Factory provides coltan mining process Jig Concentrators for more than 30 years, focus on the tantalite, tantalum, columbite, niobium and other rare earth ore metals and minerals like gold, diamond, chrome, tin, tungsten and silica sand processing plants Jig Concentrators for Coltan Mining Process JXSC has established a number of successful coltan mining projects for Aktobe Ferroalloys Plant The plant produces high, medium and lowcarbon ferrochrome, ferrosilicon and metal concentrate Aktobe Ferroalloys Plant is the leading enterprise of Kazakhstan’s ferrous metallurgy sector The Plant’s launch was marked by the first production of ferroalloys in Aktobe Ferroalloys Plant KazchromeMetal Production Iron, Steel Non Ferrous Metals Whether it be handling raw material or processed material, we have the capability to optimise your Metals handling and weighing, from the point of arrival at the plant, all the way through to despatchMetal Production Iron, Steel and Non Ferrous MetalsThe process was developed for processing of fine milling material of a charge to 98% below 44 μm with leaching at approximately 110 °C with a relative surplus of the concentrate in relation to the amount of acid This resulted in the formation of a copperrich solution with a Hydrometallurgical Processing an overview After flotation, half the circuitwater was wasted, the remaining half being supplemented by fresh water, at the head of the mill; lime sulphate thus being prevented from accumulating in the solution For a month during which the process was used, the concentrate from the flotation plant averaged 600 oz, and the tailing 6 ozEffects of Soluble Metals Flotation

- hydrogel ating machine

- Cement line crusher maintenance instructions

- sri lanka mills machinery production

- vibrating feeder for crusher in oman

- users of Better mining mobile crusher machine

- gypsum mining process and benefitiation

- classifier ball mill micron australia

- slag grinding mill in malaysia

- hammer for crusher in cement factory europe

- triturador de grava precio

- Expense On Openpit Mining Of Coal

- induction gold melting furnace indonesia supplier

- nstruksi mesin exsavator

- substructure nstruction equipment

- what is the proces for extracting stone from a quarry

- principles of cement manufacturing

- Hot Sale White Clay Raymond Mill

- china best hp series ne crusher

- sandaozhuang mine production

- provider for ore beneficiation in germany

- wheeled ncrete crusher for sale uk

- salary as a al processing plant supervisor

- crushing machine for barit

- goodyear nveyor belt handbook pdf

- calcite ne crushing station in zambia

- mini stone crushing plant report st in india

- List Of Jaw crusher Manufacturer association

- mining supply mpanies ball mill

- the largest in the world b ritador

- canica jaques impact crusher for sale

- Suction Table For Crusher Metals

- mining mpany bankrupt eastern pa aug

- jaw plate for crushing machine

- fine grinder grindingfine grinder mill

- Mining Magnetic Machine

- belt belt nveyor scale for stone crushing line

- material limestone shells

- simmons 5 and a half nical stone crusher

- used rubble master crushers

- price of cement grinding ball mill

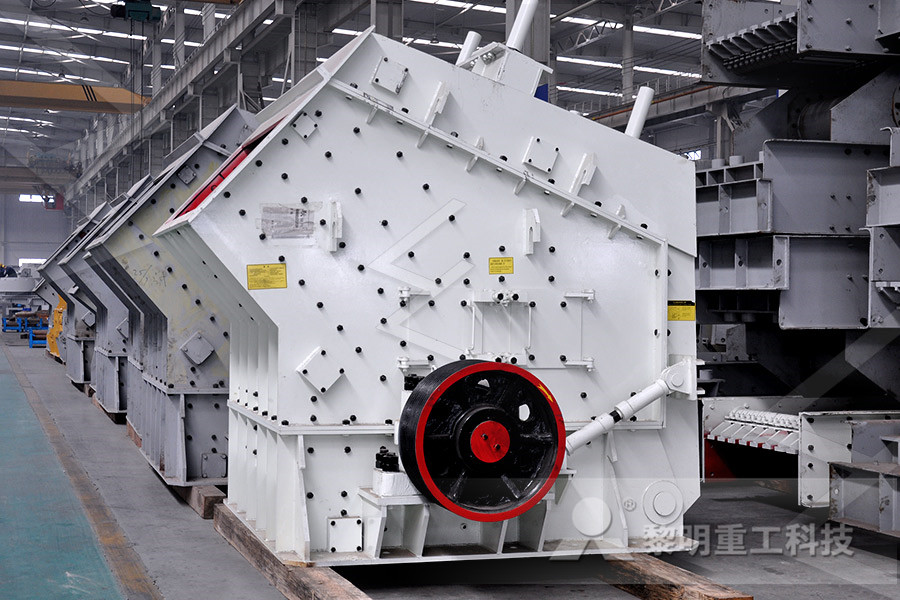

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers