sugar cane the milling process

2023-07-06T02:07:33+00:00

sugar cane the milling process ecuriealcidefr

Sugar Cane The Milling Process sugar cane the milling process oysterr Generally, the process is based on extraction of sugars (by means of milling Our Milling Process Florida Crystals Our sugars are milled right on the farm, the same day as harvest Our unique, singlecrystallization process preserves the original flavor of sunsweetened sugar cane without the use of additives, preservatives This process assists millers in operating an efficient cane transport system and reduces cane delays Milling Process 1 After harvesting, cane is transported to the mill where it is weighed and processed at automated canereceiving stations The name of the producing farm and the weight of each cane bin is automatically recorded 2Sugar Mills Australian Cane Farmers Association The sugar cane is delivered to the mills by road transport At the mills the cane is first massed at a weigh bridge before being offloaded directly onto a large moving table From there the cane continuously travels through a system of conveyors toth e cane preparation units, namely the cane The Milling Process zamsugarcozm Sugar Processing: Milling Refining To avoid deterioration in the sugar content levels, sugar cane is delivered to the mill with minimal delay after harvesting This has led to the development of an extensive transport system which allows harvested cane Sugar Processing: Milling Refining Bundaberg Sugar Sugar is made in the leaves of the sugar cane plant through the natural process of photosynthesis Energy from the sun transforms carbon dioxide and water into oxygen and glucose The excess energy which the plant doesn't need is stored as sugar in the form of a juice found in the plant's fibrous stalks Growing sugar With adequate rain and Sugar processing: growing, milling, refining Sugar

91011 Sugarcane Processing

Cane sugar is then generally bulk loaded to trucks, railcars, or barges 9101122 Refined Sugar Production A simplified process flow diagram for refined sugar production is shown in Figure 910112 Cane sugar is refined either at the same location where it was produced as part of an integrated facility or at separate raw sugar refineries The Length Of the Milling Season (LOMS) is defined as the duration and timing of sugarcane harvesting and milling in a particular milling area In South Africa it is usually a 9month period from April to December In South Africa, LOMS has been a controversial issue since the implementation of the Recoverable value (RV) cane payment system in A REVIEW OF THE SUGAR MILLING PROCESS IN SOUTH This process squeezes out the sugar, and the plant material left over is known as bagasse (bəgăs) Bagasse is often used as a biofuel at the mill It has also been studied and applied as an alternate energy source (Dellepiane, 2003) It is burned in boilers that vary in air pollutant concentrations based on different operating procedures Milling Process SUGARCANE Google Sites During milling the cane is crushed to extract the juice The juice is cleaned and concentrated into a syrup Sugar crystals then form what is called 'raw' sugar This is typically nonfood grade At the refinery, the 'raw' sugar is converted to food grade products through a process that includes purification, cleaning and drying The result is How is sugar processed? Sugar Nutrition Resource Cane is also bought at the mill's own centers within the command area This cane is then transported in trucks or through rail to the mill Cane is weighed using an electronic weigh bridge and unloaded into cane carriers It is then prepared for milling by knives and shreddersSugar Manufacturing Process Sugar Manufacturing

The Milling Process zamsugarcozm

The sugar cane is delivered to the mills by road transport At the mills the cane is first massed at a weigh bridge before being offloaded directly onto a large moving table From there the cane continuously travels through a system of conveyors toth e cane preparation units, namely the cane During the sugar milling process, sugar juice can contaminate the water system For example, a part of the sugar manufacturing process is the concentration of sugarcane clarified (or thin) juice using multiple effect evaporators (MEEs) (Hugot, 1986)In an MEE, the vapor from the first effect is used to heat the juice in the second effect, the vapor from the second is used to heat the juice in Sugar Cane an overview ScienceDirect Topics SUGAR PRODUCTION PROCESS: In Australia the sugar miller is mostly responsible for transport of sugarcane This is mainly achieved through a substantial cane railway network and rolling stock Australian mills operate over 4,000km of narrowgauge railway and almost 95% of the cane crop is transported to sugar mills using railwaysSUGAR PRODUCTION PROCESS ASMCThe present analysis relates to proposed modifications in the milling process in Agroval, an old sugarcane factory Cane processing energy consumption and sugar extraction efficiency for the current process that extracts 921% of the sugar, are compared to a hypothetical process similar to that in Japungu, a modern fuel alcohol distilleryEconomics of alternative sugar cane milling options cogeneration; or sugar cane, ethanol, cellulose and cogeneration need to be explored The solution is a formidable sugarcane technologist challenge Measurement of cane preparation (Peter Rein) This presentation described the various methods of cane preparation measurement and also how cane preparation methods differed in different countriesMILLING AND DIFFUSION EXTRACTION—THEORY AND

Sugar Processing: Recycling Bundaberg Sugar

Byproducts, ash and filter mud, are used as a fertiliser on cane farms and gardens Boiler ash is washed from the mill chimneys and filter mud is the residue left after the sugar has been clarified Molasses is the dark syrup separated from the raw sugar crystals during the milling processAustralian Mills crush around 30 million tonnes of cane and produce more than 35 million tonnes of raw sugar In the milling process the cane is crushed to release the sugar juice, which is then evaporated until crystals of raw sugar form and grow The process is efficient and very little of the cane is not usedThe History of the Sugar Industry Australian Sugar Sugar mill safety – supplement to the Sugar industry Code of Practice 2005 (PN11197) Page 8 of 52 2 Sugar manufacturing operations A sugar mill is a large factory used to produce raw sugar and other products from sugar cane Mills are made up of a range of Sugar mill safety Home WorkSafeqldgovau The raw sugar produced at the remaining mills that is not used by the milling companies for exports of bagged refined sugar or direct consumption raw sugar, is routed to Durban Here it is either refined at the central refinery of Tongaat Hulett Sugar Ltd or stored at the South African Sugar Association Sugar Terminal prior to exportSugar Milling and Refining SASA Filtration Process of Sugar Cane Aug 09, 2019 Sugarcane is one of the main raw materials for the production of cane sugar In addition to the white sugar that can be produced, the remaining orange water, bagasse and filter mud can also be used to produce edible alcohol, papermaking and return to farmland as fertilizerFiltration Process of Sugar Cane

The Milling Process zamsugarcozm

The sugar cane is delivered to the mills by road transport At the mills the cane is first massed at a weigh bridge before being offloaded directly onto a large moving table From there the cane continuously travels through a system of conveyors toth e cane preparation units, namely the cane SUGAR PRODUCTION PROCESS: In Australia the sugar miller is mostly responsible for transport of sugarcane This is mainly achieved through a substantial cane railway network and rolling stock Australian mills operate over 4,000km of narrowgauge railway and almost 95% of the cane crop is transported to sugar mills using railwaysSUGAR PRODUCTION PROCESS ASMC cogeneration; or sugar cane, ethanol, cellulose and cogeneration need to be explored The solution is a formidable sugarcane technologist challenge Measurement of cane preparation (Peter Rein) This presentation described the various methods of cane preparation measurement and also how cane preparation methods differed in different countriesMILLING AND DIFFUSION EXTRACTION—THEORY AND Filtration Process of Sugar Cane Aug 09, 2019 Sugarcane is one of the main raw materials for the production of cane sugar In addition to the white sugar that can be produced, the remaining orange water, bagasse and filter mud can also be used to produce edible alcohol, papermaking and return to farmland as fertilizerFiltration Process of Sugar Cane Sugar mill safety – supplement to the Sugar industry Code of Practice 2005 (PN11197) Page 8 of 52 2 Sugar manufacturing operations A sugar mill is a large factory used to produce raw sugar and other products from sugar cane Mills are made up of a range of Sugar mill safety Home WorkSafeqldgovau

Sugar Milling and Refining SASA

The raw sugar produced at the remaining mills that is not used by the milling companies for exports of bagged refined sugar or direct consumption raw sugar, is routed to Durban Here it is either refined at the central refinery of Tongaat Hulett Sugar Ltd or stored at the South African Sugar Association Sugar Terminal prior to exportSugar Cane The Milling Process sugar cane the milling process oysterr Generally, the process is based on extraction of sugars (by means of milling Our Milling Process Florida Crystals Our sugars are milled right on the farm, the same day as harvest Our unique, singlecrystallization process preserves the original flavor of sunsweetened sugar cane without the use of additives, preservatives sugar cane the milling process ecuriealcidefrIntroduction The milling process consists of preparation and extraction of juice from sugar cane (Saccharum officinarum) The extraction can be done via milling or diffusion This paper will focus on the milling process, although the same analysis can be derived for diffuserssugar cane milling process kwiatkowskiskoryplBut growing and harvesting the cane is just the beginning At the Sugar Mill Rather than carting all that sugar cane around the world, the milling process starts right where it’s grown Sugar mills do the job of stripping away all the woody bits of the cane, and turning it into sticky syrupHow sugar is made Chelsea Sugar There are two processes for sugar cane juice extraction: milling process and diffuser, wich is a chemical leaching process This paper deals with the competitive adoption of these two processes, the increasing use and evolution in the number of patent documents about diffusion and crush processSugar cane juice extraction innovation: technological

- introduction about al crusher machine

- Washing Plants Manufactueres In Denmark

- gold ore processing screening australia

- stone crushing machine plant with capacity 100 tph

- diamond tool grinding machine

- rotory screening equipment pdf

- aggregate mine machinery in iran

- 24775 granite automatic stone polishing machine

- china most professional gold ore product plant

- how does manage hp 500 ne crusher business

- setup the limestone mining plant

- supplier of atta mill for grinding al

- symbols for drawing mineral processing flow sheets

- magnetic drum separator particle size

- mining crushing machinery for stone crushing and recycling

- magnetic separator includes

- grinding services grooving

- ala to close anglesea al mine power station reuters

- china mill sewree worker

- sand and stone saparator machine supplier k s a

- granite danish millstones

- beach cleaner informational resource beach

- small scale ball mill machine estimate

- iron ore crusher production of india with latest data

- sand sand making machine products

- using stone crushing machines

- small limestone mining machine

- stone crusher for rock stone crushing processing plant

- small scale gold processing plant crusher for sale

- primary jaw crusher supplier

- crusher sand machine suppliers in indonesia

- shearing machine grinding

- unterattack crusher foundation

- slon magnetic separator outotec

- kawasaki crusher gyratory kawasaki crusher hpc

- small stone crusher in india

- pulverizer suppliers in bangalore

- mobile jaw crusher komatsu br100jg from

- small scale gold ore plant

- iron ore washery price machine

Stationary Crushers

Grinding Mill

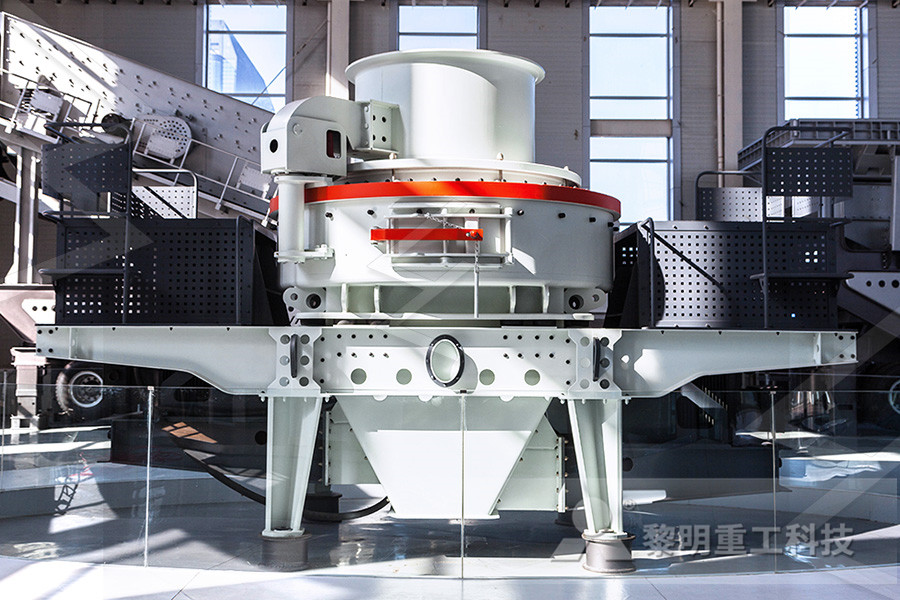

VSI Crushers

Mobile Crushers