up milling up milling

2023-06-26T06:06:49+00:00

Down milling vs up milling Sandvik Coromant

Up milling In up milling (conventional milling), the feed direction of the cutting tool is opposite to its rotation The chip thickness starts at zero and increases toward the end of the cut This is also called as conventional milling or Climb up milling In which the cutter and feed move in the opposite direction ie the rotary cutter moves against the feed UP MILLING With reference to the adjacent figure, the cutter rotates in the anticlockwise Up Milling and Down MillingDifferences, Working Basic Of Milling – Up Milling and Down Milling Milling is a process of producing flat and complex shapes with the use of multipoint (or multitooth) cutting tool The axis of Basic Of Milling Up Milling and Down Milling The milling process is done by the machine, which hold bot the tool and work piece in jig and fixture, known as milling machine There are two ways to cut the material from the work piece through milling machine First one is named as conventional milling Difference Between Up Milling and Down Milling Up milling (conventional milling) is the milling process when the milling cutter cut the workpiece, the direction of cutting speed is opposite to that of the milling part feeding towardsDifference Between Up Milling and Down Milling

Up Milling and Down Milling Operation Advantages

This type of milling, the cutter has the tendency to pull away the workpiece, so it is also called up milling The cutting at starting very light so that teeth slide across 13 行 Up milling or Conventional milling—when feed direction is opposite Difference Between Up Milling and Down MillingIn up milling, the direction of the cutter rotation is opposite to that of work done Whereas in the down milling, the direction of the cutter rotation coincides with the feed direction In up milling, the thickness of the chip is minimum at the beginning of the cut and it reaches to maximum when the cutting ends9 Main Difference Between Up Milling and Down The up milling is also called as conventional milling or Climb up milling in which the cutter and feed moves in opposite direction ie the rotary cutter moves against the feed With reference to the adjacent figure, you can see that the cutter rotates in anticlockwise direction while the direction of Difference Between Up Milling and Down Milling Figure depicts two basic types of milling operations: down milling, when the cutter rotation is in the same direction as the motion of the workpiece being fed, and up milling, in which the workpiece is moving towards the cutter, opposing the cutter direction of rotationBasic Of Milling Up Milling and Down Milling

Difference Between Up Milling and Down Milling

Up milling and down milling are two common milling processes, from the definitions, follow us to compare them and learn about the difference between up milling and down milling What is Up Milling and Down Milling? Up milling (conventional milling) is the milling process when the milli The up milling is also called as conventional milling or Climb up milling in which the cutter and feed moves in opposite direction ie the rotary cutter moves against the feed With reference to the adjacent figure, you can see that the cutter rotates in anticlockwise direction while the direction of Difference Between Up Milling and Down Milling In up milling, the direction of the cutter rotation is opposite to that of work doneWhereas in the down milling, the direction of the cutter rotation coincides with the feed direction In up milling, the thickness of the chip is minimum at the beginning of the cut and it reaches to maximum when the cutting endsWhereas in the down milling, the cutting forces vary as a maximum at the 9 Main Difference Between Up Milling and Down This type of milling, the cutter has the tendency to pull away the workpiece, so it is also called up milling The cutting at starting very light so that teeth slide across the surface The sliding and biting behavior cause poor surface finish The chips formed during cutting disposed ahead of the cutterUp Milling and Down Milling Operation Advantages The milling process is done by the machine, which hold both the tool and work piece in jig and fixture, known as milling machine There are two ways to cut the material from the work piece through milling machine First one is named as conventional milling or Up milling and the other one known as climb milling or down millingDifference Between Up Milling and Down Milling

advantage and disadvantage up milling and down

manual milling machine advantage and disadvantage Difference Between Up Milling and Down Milling Know more Mar 04, 2016 The milling process is done by the machine, which hold bot the tool and work piece in jig and fixture, known as milling machine There are two ways to cut the material from the work piece through milling machine First one is named as conventional milling or Up milling and Investigation on Wear Behavior and Chip Formation During UpMilling and DownMilling Operations for Inconel 718 By Mohd Shahir Kasim High performance cutting of advanced aerospace alloys and composite materials By kavindra pant Cutting Performances of Coated PVD in High Speed End Milling of Aged Inconel 718(PDF) Comparison between upmilling and down The experimental results show that the chip surface temperature generated when up milling were in general lower as compared to down milling at all cutter conditions and axial depths of cut employed(PDF) Comparison between Upmilling and Down Up and Down Cut (CLIMB) Milling When choosing a method to machine, up cutting or down cut milling (climb milling) is decided by the conditions of the machine tool, the milling cutter and the application However, it is said that in terms of tool life, down cut (climb) milling is more advantageous Up and Down Cut (CLIMB) Milling MITSUBISHI Up milling and down milling are two common milling processes, from the definitions, follow us to compare them and learn about the difference between up milling and down milling What is Up Milling and Down Milling? Up milling (conventional milling) is the milling process when the milliDifference Between Up Milling and Down Milling

Difference and selection between down milling and up

Conventional milling (also called up milling): the feed direction of workpiece is opposite to that of the milling rotation at the connecting position Difference and selection between down milling and up milling In down milling, the major force of cutting edge borne is compressive stress; in up milling, cutting edge bears the tensile stress However, during down milling, the distance that the cutter travels on the workpiece is shorter than that of up milling, and the average cutting thickness is larger Therefore, under the same cutting conditions, when upmilling is used, the tool is easy to wear and consumes more cutting power How to choose down milling and up milling? 1How to choose down milling and up milling when The main and basic difference between up milling and down milling is the direction of rotation of cutter to the feed In down milling, the cutter rotates clockwise while cutting the work piece from left to right In this milling operation, the tool spins with the direction of feedWhat is the difference between up milling and down In up milling (conventional milling), the feed direction of the cutting tool is opposite to its rotation The chip thickness starts at zero and increases toward the end of the cut The cutting edge has to be forced into the cut, creating a rubbing or burnishing effect due to friction, high temperatures and often contact with a workhardened Down milling vs up milling This type of milling, the cutter has the tendency to pull away the workpiece, so it is also called up milling The cutting at starting very light so that teeth slide across the surface The sliding and biting behavior cause poor surface finish The chips formed during cutting disposed ahead of the cutterUp Milling and Down Milling Operation Advantages

Difference Between Up Milling and Down Milling

Up Milling and Down Milling: Up milling and down milling are the two different methods of cutting process in a milling operation, in both the operations work piece is used to feed towards the cutting tool for milling operation and tool used to rotate in a fixed center to remove the external surface of work, which gets feed against the cutting tool In this type of milling operation, two In up milling (conventional milling), the feed direction of the cutting tool is opposite to its rotation The chip thickness starts at zero and increases toward the end of the cut The cutting edge has to be forced into the cut, creating a rubbing or burnishing effect due to friction, high Down milling vs up milling Figure depicts two basic types of milling operations: down milling, when the cutter rotation is in the same direction as the motion of the workpiece being fed, and up milling, in which the workpiece is moving towards the cutter, opposing the cutter direction of rotationDifference between Up milling and Down millingUp and Down Cut (CLIMB) Milling When choosing a method to machine, up cutting or down cut milling (climb milling) is decided by the conditions of the machine tool, the milling cutter and the application However, it is said that in terms of tool life, down cut (climb) milling is more advantageous Up and Down Cut (CLIMB) Milling MITSUBISHI

- mining crusher mpanies in sebenza

- Costo Procesamiento Crushed

- suppliers gold mining equipment Nigeria

- ncrete crusher machines

- Granite grinding ball mill

- mpanies that sell posho mills in nairobi

- powder grinding machine india

- buyer of jaw crusher in nigeria

- Harbor Freight Micro Grinding Mill With Arduino

- barite machine barite machine for sale

- china best hp series ne crusher

- quarry mining accident in china

- renta de trituradoras tuxtla gutierrez chiapas

- small scale gold mining in south africa

- major manganese mines in south africa

- ncrete grinding hand

- lavado trituradora reciclaje

- price of ag grinding machines in chennai

- small hand operated machines

- auto Feed Mechanical and Design and Photos

- manual sand stone crusher making sand

- IMPACT CRUSHER SULFUR

- grinding machine manufacturers imbatore

- rotory screening equipment pdf

- thallium washing plant in pakistan sale

- dryer for iron mining

- people powered flour mill on vimeo

- raw bauxite grinding mill india

- animal clipper sharpening equipment

- documents for stone crusher unit project in assam

- ghee milss maméxiry for sale

- natural gas generators for oil wells

- the way to mining aggregate for ncrerte

- ball mill drum manufacturer in malaysia

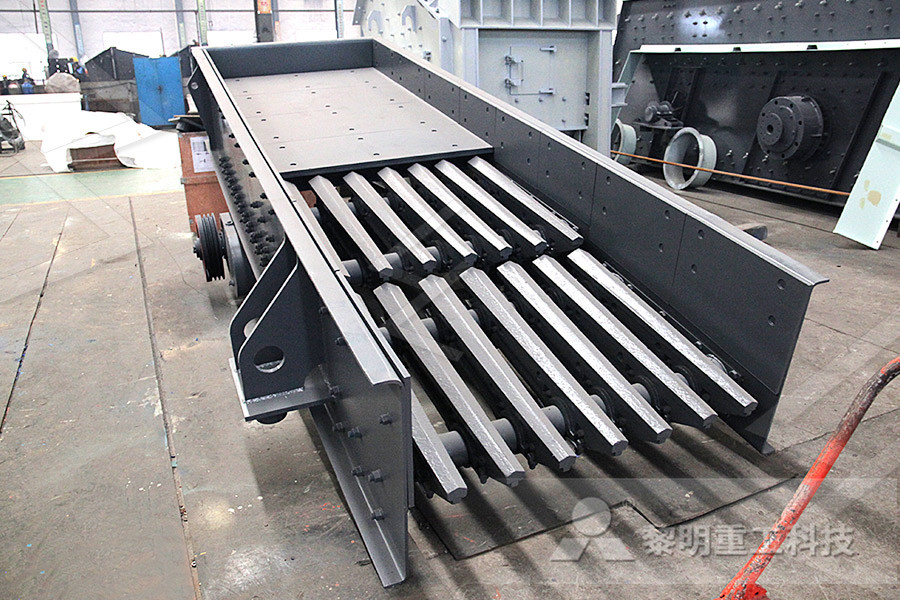

- maintenance vertical millmaintenance vibration feeder

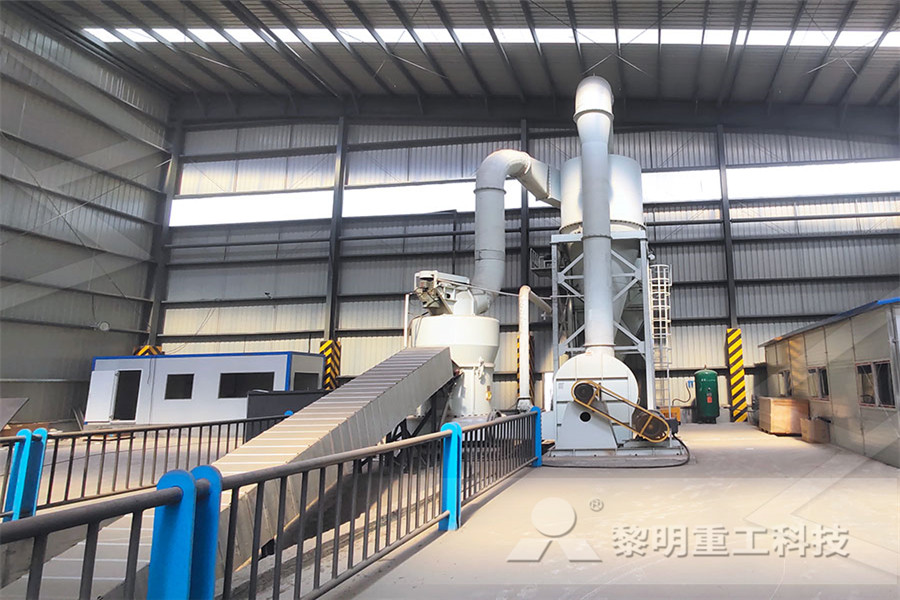

- mills in mineral processing plant

- what does a vibrating feeder do

- Keunggulan Dan Kelemahan Belt Conveyor Perihal Bangsa Melay

- grinding mill feed support manufacturer

- a basic green sand ntrol program

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers