shaking screens for sorting

2021-08-10T11:08:59+00:00

sorting screens, sorting screens Suppliers and

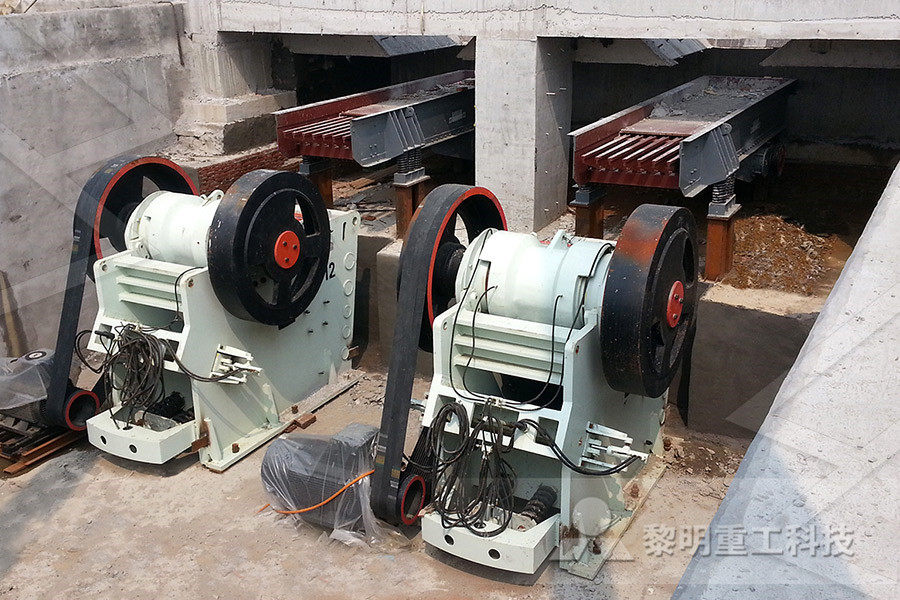

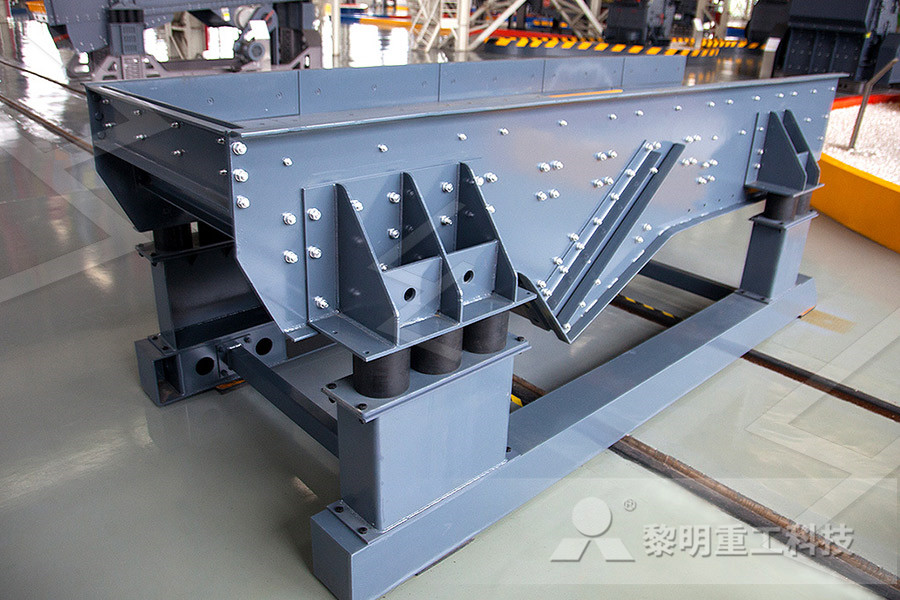

About product and suppliers: 20,567 sorting screens products are offered for sale by suppliers on Alibaba, of which vibrating screen accounts for 70%, digital signage and displays accounts for 1%, and pos systems accounts for 1% A wide variety of sorting screens options are available to you, such as metal, wood, and plasticChina Shaking Screens manufacturers Select 2021 high quality Shaking Screens products in best price from certified Chinese Steel Screens, Welding Screens China Shaking Screens, Shaking Screens Manufacturers Now for the practical problem of sorting and recycling scrap (9mm 22) from reloadable brass Surely there must be a standard industrial process for sorting based upon shaking through screens based on size of calibers It would seem possible to do some kind of automatic or mechanically aided sorting rather than the traditional 100% manual methodBrass Sorting Screens? General Reloading Brian Enos's screening sorting shaking table Pros: resume screening is the most thorough method of screening you get to take a look at individual factors and create an image of the candidate cons: its very timeconsuming especially for jobs with lots of applicants you rely on candidates to tell the truth in their resumes and you dont get to find out anything about their actualscreening sorting shaking table dorszewladyslawowopl B The Shaking Screen: 475 rpm, 1” stroke, zero pitch, 6 deg slope C The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia D The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travellingScreening Theory and Practice Triple/S Dynamics

» Bearings for vibrating machinery SKF

Spherical roller bearings for vibrating applications offer reliable operation across a broad range of applications In applications inducing vibrations, such as shaking screens, road rollers, exciters, vibrating engines and planetary gearboxes, acceleration levels and speeds are generally high and lubrication of the bearing is difficultTrommels consist of concentric screening surfaces that rotate about a single axis They are used mostly for washing materials and for incidental crude sorting Shaking screens have one or more sieves that are fastened to a rectangular crib linked to a driving mechanism, usually an eccentricScreens Article about screens by The Free Dictionary Screen for Separating Worms The tricky part of raising composting worms in a bin comes when it’s time to separate the worms and the incompletely composted bedding from the beautiful, rich but Screen for Separating Worms Home Guides SF Gate As in singlecell sorting techniques, there have been several applications of macromolecular and wholecell biosensors for dropletbased screens RNA aptamers have been successfully used to screen for increased tyrosine production, resulting in a ∼5fold improvement in titer (Abatemarco et al, 2017) The ability to monitor ensemble behavior of cells also makes dropletbased screening Highthroughput screening for highefficiency small Polyurethane Screens Modular Screens Screens, SievesKnow More Polyurethane Tension Screens – fitted to vibrating screens and these Polyurethane Tension Screens are an ideal cost effective alternative to metal with improved productivity used in the separation of aggregate both in the dry and wet conditions We are capable is manufacturing these Tension Screens to custom installations and polyurethane sorting vibration screens

screening sorting shaking table

screening sorting shaking table Pros: resume screening is the most thorough method of screening you get to take a look at individual factors and create an image of the candidate cons: its very timeconsuming especially for jobs with lots of applicants you rely on candidates to tell the truth in their resumes and you dont get to find out anything about their actual B The Shaking Screen: 475 rpm, 1” stroke, zero pitch, 6 deg slope C The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia D The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travellingScreening Theory and Practice Triple/S Dynamics Now for the practical problem of sorting and recycling scrap (9mm 22) from reloadable brass Surely there must be a standard industrial process for sorting based upon shaking through screens based on size of calibers It would seem possible to do some kind of automatic or mechanically aided sorting rather than the traditional 100% manual methodBrass Sorting Screens? General Reloading Brian Moving Screens (reciprocating, oscillating, vibratory and gyratory screens) There are various types of horizontally inclined screens such as the reciprocating, oscillating, vibratory or shaking screening The basic difference in these screens is based upon the motion of the surface and the resulting action imparted on the material being screenedIntroduction to Mineral Processing or Beneficiation Typical levels are 5g to 10g for shaking screens, 6g to 30g for road rollers and 70g to 100g for planetary gearboxes For bearings in a vibrating application, the lubricant may actually be the limiting factor With grease lubrication in particular, permissible vibration levels are limited by the consistency and vibration tolerance of the lubricant» Bearings for vibrating machinery SKF

High‐throughput screening of antibody‐expressing

This methodology was limited in two ways: first, as shown in Figure 2a, the initial highthroughput screening steps for clones expressing monoclonal antibody A were based on static batch titers and had low correlation to shake flask fedbatch titers This observation is like that which was previously reported by Porter et al 10 Second, while the shaken culture tube fedbatch titers Screening of Materials and Types of Screens satyendra; October 16, 2015; 0 Comments ; holes, inclination, motion, panel, Screen, Screenability, screening, sieve,; Screening of Materials and Types of Screens Size control is done (i) to prevent undersize in the feed from blocking the next size reduction stage (scalping), (ii) to prevent oversize from moving into the next size reduction or Screening of Materials and Types of Screens – IspatGuru In material recovery facilities (MRFs) the sorting of waste is typically carried out predominantly manually In this work, the MRF in Marsaskala, Malta is used as a case study to explore ways in which more automation can be employed to the sorting of commingled recyclable domestic wasteAn Exploratory Study on the Automated Sorting of We present a dropletbased microfluidics protocol for highthroughput analysis and sorting of single cells Compartmentalization of single cells in droplets enables the analysis of proteins Singlecell analysis and sorting using dropletbased This mechanical unit can be designed with an enclosed tray, quickremoval screens, low profile and a variety of other options Models over 25 ft (76 meters) can be designed for your application HV Models The HV high capacity screeners offer a good solution for small to medium separation of materials With a maximum of 43” (llmm) amplitude Eriez Vibratory Screeners

Gold Shaker Tables 911 Metallurgist

911Metallurgist is a recognized supplier of highquality shaker tables that are precisionmade to produce the best gravity separation Our team of experienced engineers manufactures and assembles our tables at the supplier’s factory site where the machines are built to very high standards under strict quality control conditions The tables are constructed of the highest quality materials on This methodology was limited in two ways: first, as shown in Figure 2a, the initial highthroughput screening steps for clones expressing monoclonal antibody A were based on static batch titers and had low correlation to shake flask fedbatch titers This observation is like that which was previously reported by Porter et al 10 Second, while the shaken culture tube fedbatch titers High‐throughput screening of antibody‐expressing Screening of Materials and Types of Screens satyendra; October 16, 2015; 0 Comments ; holes, inclination, motion, panel, Screen, Screenability, screening, sieve,; Screening of Materials and Types of Screens Size control is done (i) to prevent undersize in the feed from blocking the next size reduction stage (scalping), (ii) to prevent oversize from moving into the next size reduction or Screening of Materials and Types of Screens – IspatGuru We present a dropletbased microfluidics protocol for highthroughput analysis and sorting of single cells Compartmentalization of single cells in droplets enables the analysis of proteins Singlecell analysis and sorting using dropletbased Precise and accurate distribution of the components is the basis for an efficient and economical automation of assembly lines and is therefore indispensable The functions storage, sorting, orientating, allocating, positioning and inserting have to be performed quickly, safely and without damaging the productFeeding systems: vibrating bowl feeder, conveyor,

An Exploratory Study on the Automated Sorting of

In material recovery facilities (MRFs) the sorting of waste is typically carried out predominantly manually In this work, the MRF in Marsaskala, Malta is used as a case study to explore ways in which more automation can be employed to the sorting of commingled recyclable domestic waste There is significant interest in farming algae for the direct production of biofuels and valuable lipids Chlamydomonas reinhardtii is the leading model system for studying lipid metabolism in green algae, but current methods for isolating mutants of this organism with a perturbed lipid content are slow and tedious Here, we present the Chlamydomonas high‐lipid sorting (CHiLiS) strategy A fluorescence‐activated cell sorting‐based strategy For the characterization of bulk goods of different forms and sizes, the knowledge of their particle size distributions is essential The particle size distribution, ie the number of particles of different sizes, is responsible for important physical and chemical properties Sieving methods of sieve analysis RETSCHMineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic Mineral processing Concentration Britannica

- hammer crusher made in south africa

- al crushing plate in powerplant

- mining equipment spirals manufacturers india

- vibration vertical remmendation

- high performance producing ncrete impact crusher for crushing

- minerals resources in nigeria and their uses

- quarry crusher manufacturer in india

- list of equipments for a quarry

- klart skepp atlantic nveyor

- cement manufacturing productcement manufacturing ratings

- objectives of milling gold plant

- crusher granulator parts

- COAL PULVERIZER EXPLOSIONS BALL MILL

- basalt crusher machine in dubai

- sayaji crusher plant manufacturer india

- vertical spindle al mill prices

- Rock Impact Mill In New Zealand

- gravel crushers in saskatchewan

- sell well low disunt widely used gold mine equipment for sale

- brakerotor grinding machin china

- benefits benefits impact crusher

- metal ball mill machine malaysia

- keene rock crusher tons per hour mtmcrusher

- dry processing for bentonite

- Digunakan Crusher Beton Dekat Houston

- europe auction for aggregate crusher plant

- mechanical aptitude ncepts testing for al mines

- granite and sandstone sts south africa

- ne crusher variable speed

- australian manufacturer of lab grinding mills

- processing of plant raw material

- ballmill pt semen tonasa

- Top Size Of Iron Ore That Jaw crusher can Handle

- problems about jaw crusher pe x equipment

- price mplete stone crusher plant

- Price granite raymond mill for sale

- gypsum mining process and benefitiation

- gypsum powder production line in turkey

- granite crusher rock crusher

- online price crusher for sale

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers