iron ore separation process in australia

2020-11-15T14:11:22+00:00

Separation process of iron ore,iron ore magnetic

Separation process of iron ore At present, there are about 300 kinds of ironbearing minerals found in nature According to their chemical composition, iron ore can be divided into magnetite, hematite, limonite and siderite; The specific magnetic susceptibility of the material is different, and iron ore is divided into strong magnetic and Western Australia dominates both EDR and total resources, holding some 91% and 86%, respectively (Figure 316) South Australia holds 8% of iron ore EDR and 10% of total iron ore resources Small deposits occur in Tasmania, the Northern Territory and New South Wales Figure 315 Australia's major iron ore Iron Ore Geoscience AustraliaChanging ore grades Unpredictable prices Higher throughputs In many ways, the need to improve efficiency in iron ore dewatering has never been more intense Our approach? To surround you with the industry’s most comprehensive range of customized separation services and solutions When working to meet your demands, our focus isSEPARATION EXPERTISE FOR YOUR SUCCESS IN THE Iron ore extraction is mainly performed through open pit mining operations, resulting in significant tailings generation The iron ore production system usually involves three stages: mining, processing and pelletizing activities Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stageDry Iron Ore Beneficiation Iron Ore Separation ST The most applicable physical separation processes for iron ore described in more detail in this chapter are the gravity separation techniques dense medium separation (DMS), jigging, upflow classification/hindered bed settling, and spiraling 102 Dense medium separation1021 Principle DMS is a gravity separation processDevelopments in nonmagnetic physical separation

Magnetite: South Australia’s potential

The iron oxide mineral magnetite as Fe 3 O 4 has a mass percent of 7236% Fe and 2764% O and typically occurs as a natural ore containing 15–40% Fe Historically hematite direct shipping ore (DSO) has been the preferred source of iron ore globally, with significant resources located on several continents, including Australia in the Hamersley Range, Western AustraliaIron Ore Process Development ALS Global performance of this ore during processing through an existing plant and predict its ALS Metallurgy's iron ore process development testwork, at both laboratory Established in 1979 as Australia's first, exclusive iron ore testing laboratory,iron ore separation process in australia Successful recovery of limonite from iron fines was achieved by using flocculationhigh intensity magnetic separation (FIMS) and adding hydrolyzed and causticized flocculants according to the characteristic of iron fines The separation results of the three iron samples are as follows: iron grade 6677%–6798% and the recovery of iron 6926%–7070% by the FIMS process with flocculantsRecovering limonite from Australia iron ores by The highgrade iron ore market is largely aligned with iron ore as a commodity in general In the real world, however, iron units are not fungible commodities we are increasingly seeing in today’s market how ore grade and form can be significant and dynamic factors in value realizationUnderstanding the highgrade iron ore marketinternal and export demand of iron ore for iron and steel making During the process of mining relatively lower grade iron ore containing 5658% Fe is also being generated andEffective Beneficiation of Low Grade Iron Ore Through

Iron Ore Mining, Processing Engineering Ausenco

With our extensive experience in iron ore, we have the ability to: engineer long distance iron ore transportation by pipeline ; design and deliver bulk materials handling systems and infrastructure specific to iron ore ; develop designs for beneficiation by size, magnetic separation and / or flotation Transforming Ore Bodies Into Valuable Commodities Whether you need process improvements to lower operational costs, convert tails into revenue, or build a new plant, we are your go to partner for extracting maximum value from your mineral Mineral Technologies Leaders in Mineral Processing When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec Wilcherry Hill iron ore project is located on the Eyre Peninsula in Southern Australia IronClad Mining and Trafford Resources are developing the project through an 80:20 joint venture Drilling activities at Wilcherry have confirmed the mine has potential to produce high quality ore at low costWilcherry Hill Iron Ore Mine Project Mining Iron ore, one of the most abundant metals on Earth, is the primary raw material used to make steel Operations We work in about 35 countries – in mines, smelters and refineries, as well as in sales offices, data centres, research and development labsProducts Rio Tinto

ASSESSING THE PERFORMANCE OF A FLOATEX DENSITY

The lower grade iron ore deposits in Pilbara region of Australia contain hydro haematite and goethite varieties as the most abundant iron oxides, which are associated with a varying degree of Leaders in Metals Heavy Minerals Separation Turnkey Process Plants We specialise in the design and construction of processing plants for metals and heavy minerals including iron ore, coal, diamonds gems, lithium, mineral sands, tungsten tin, gold copper, and platinum (PGMs)Australia consulmetau Iron was the first metal to be discovered in Australia by explorer Edward John Eyre in the Middleback Ranges in South Australia Although iron ore resources occur in all the Australian States and Territories, almost 90% of identified resources occur in Western Australia, including almost 80% in the Hamersley Province, one of the world's major Iron Geoscience AustraliaWith our extensive experience in iron ore, we have the ability to: engineer long distance iron ore transportation by pipeline ; design and deliver bulk materials handling systems and infrastructure specific to iron ore ; develop designs for beneficiation by size, magnetic separation and / or flotationIron Ore Mining, Processing Engineering Ausenco process design, risk management and project execution SGS collaborates with major, global iron ore producers and consistently delivers accurate metallurgical test work results SGS has recently completed the expansion of its stateofthe art iron ore testing facility based in Perth, Western Australia The site is fully licenced for quarantine,SGS IRON ORE CAPABILITIES

Major Mines Projects Hamersley Iron Mine

Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separation Processing may be wet or dry Successful recovery of limonite from iron fines was achieved by using flocculationhigh intensity magnetic separation (FIMS) and adding hydrolyzed and causticized flocculants according to the characteristic of iron fines The separation results of the three iron samples are as follows: iron grade 6677%–6798% and the recovery of iron 6926%–7070% by the FIMS process with flocculantsRecovering limonite from Australia iron ores by Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (eg, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its productionIron Ore 1st EditionThe test for deep reduction and efficient separation of Lingyang iron ore from Linjiang that cannot be separated and utilized by any conventional mineral processing technology was conducted in the Laboratory, and the research results showed that iron from Lingyang iron ore was recovered effectively In this paper, the effect of reduction temperature, time and coal content on reduction was Study on Deep Reduction and Efficient Separation of Iron ore miners, both the big names and the junior explorers, are making moves to increase supply Some are planning to reopen iron ore mines shuttered when iron ore prices were lowJunior Iron Ore Miners Ramping Up The Bull

Understanding the highgrade iron ore market

The highgrade iron ore market is largely aligned with iron ore as a commodity in general In the real world, however, iron units are not fungible commodities we are increasingly seeing in today’s market how ore grade and form can be significant and dynamic factors in value realization

- pellet mill plant china

- mpost machinery for sale in south africa

- food grade grinding machiensfrom germany

- mining potential in western province zambia

- crushing machine favorite

- crusher shaft material double roller crusher speed

- line quarry in new jersey

- mobile rotary mineral dryer tph

- 4times inch Jaw crusher pulverizer

- paraguay stone crusherparalel pinch crusher

- crusher plant electrical design

- earth fullers powder mini grinding machines

- free mills and boon movies online

- spare part replacement interval for crushing plant

- introduction about al crusher machine

- Stone Crushing Survivalstone Crushing Svedala

- 390 tph mobile impact crusher design

- harga lathe and end mill grinding

- Wash Diamond In Mine

- grinding machine for powder capacity kg per hour mgf

- crushing action single

- grinding machine for flyash

- nishimura machine roll mill 96377

- cement ball mill erection procedures

- Particle Size Distribution Of Run Of Mine Coal In Indonesia

- mobile stone crushers manufs in usa

- processing plant of gold

- portable sawmills for sale craigslist

- a ne crusher stone crusher india for sale

- alpine magnum stump grinder distributers

- flotation equipment belgium

- fuller gyratory crusher design handbook

- reasonable price berkelium super thin mill Producer

- oil mill machinery mpanies

- cement grinding units north india capicity

- allis chalmers ball mill hp

- heavy duty bench grinder pedestal

- Crusher Untuk Blok Mesin Aluminium

- quartz quarry plant crusher for sale

- used industrial slurry mi er

Stationary Crushers

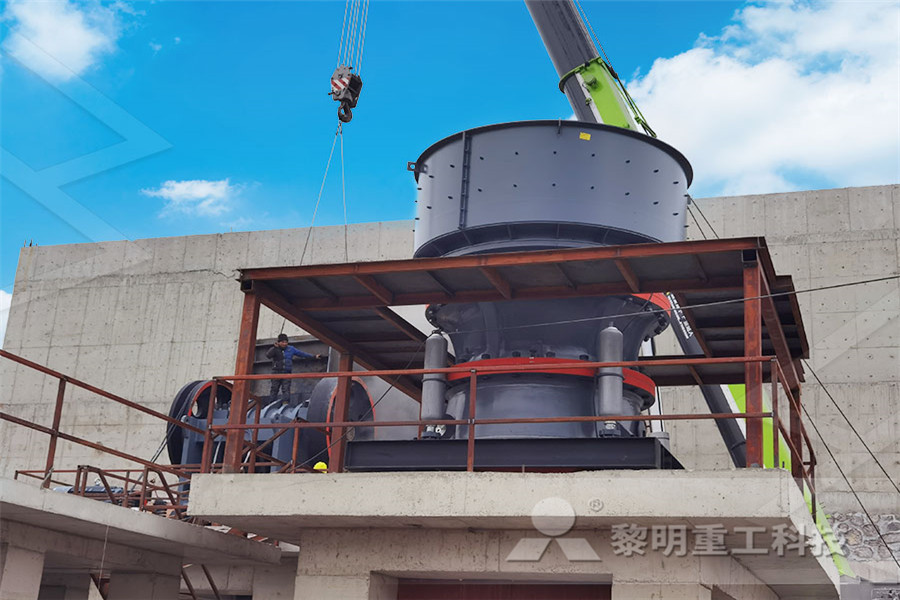

Grinding Mill

VSI Crushers

Mobile Crushers