manganese rock crusher wear parts

2021-06-22T16:06:33+00:00

Rock Crusher Wear Parts amcastonline

Explore Amcast's full line of rock crusher wear parts and the technology that sets the bar for performance and durability Explore Amcast's full line of rock crusher wear parts and the technology that sets the bar for performance and durability Amcast offers 3 main lines of Manganese to suit your specific application 1 Amcast's Non Crusher Manganese Supplying Premium Manganese Steel Crusher Liner all castings are manufactured to strict quality control and managed guidelines We have more than 25 years’ experience in Designing, Sourcing, Manufacturing, Selling and Fitting Liners to all makes and models of Rock CrusherCrusher Manganese Mining Wear PartsRock Cone Crusher Wear Parts; Manganese is the most common material for making cone crusher wear parts Because manganese provides mounting possibilities, reliability, and shear strength to the wear parts It also enhances the life of all components Mantles, bowl liners, and concaves are made of Mn14, Mn18, and Mn22Rock Crusher Wear Parts Rock Crusher Spare Parts Sandrock Mining is a growing company with years of experience in produce and supply of wear parts such as the Bowl Liner, Mantle, Jaw Plate, Cheek Plate, Hammer, Frame, Linerand spare parts such as Bushing, Shafts, Gears, and so onCrusher Manganese Parts Sandrock MiningHigh Manganese Stone Crusher Parts Jaw Crusher Wear Parts Spare Parts Jaw Plate Stone Crusher Parts Jaw Crusher Wear Parts Introduction: The jaw crusher wear parts can also be called the jaw crusher consumables and are an important part of the jaw crusher; they need to be replaced within a certain period of timeHigh Manganese Stone Crusher Parts Jaw Crusher

Crusher wear parts Outotec Momentum

Our crusher wear parts are carefully manufactured from highquality manganese in a specified and continuously monitored process at our own foundries and manufacturing facilities We have complete control over quality at every step of the process, from the Manganese parts are available in 14% Standard, 18% Premium, and 22% High alloys CWP offers custom profile bowl liners and mantles available in stepped, pocketed, and increased feed versions of OEM partsThese custom parts can lead to increased efficiency, longer wear life, and reduced downtime therefore lowering overall production costsCone Manganese Liners Crusher Wear Parts 4 Crusher Wear Parts Reference Guide Crusher Wear Parts Reference Guide 5 WEAR PARTS OVERVIEW METALLURGY OPTIONS JAW LINERS 18% Manganese Standard fit on all jaw crushers This is a liner suitable for all applicationsCRUSHER WEAR PARTS Then there is the presence of other elements in the alloy – carbon increases the hardness and wear resistance of the alloy, and chromium helps prevent ‘metal growth’ (where the liner expands and becomes too large for the crusher) Getting the right ratio of these elements relative to manganese is a delicate balanceManganese steel wear liners Sandvik Mining and 2 Jaw Crusher Wear Parts 3• Cone Crusher Wear Parts 4 Impactor Crusher Wear Parts Topics within these sections include metallurgy options , liner profiles available , application examples , case studies , wear part codes etc I hope this Guide provides an invaluable source of information that will assist you in selling Finlay crusher R Crusher Wear Parts Reference Guide

Rock Crusher Wear Parts Nanjing Manganese

MGS Casting is the leader in high quality, manganese, chrome, and our patented TIC insert wear parts for various brands rock crusher We produce castings for aggregate crushing and mining We are a proven, high production steel and high chrome iron casting operation and are recognized for design and manufacture of unique, complex products with Alibaba offers 2,379 rock crusher wear parts products A wide variety of rock crusher wear parts options are available to you, such as local service location, material, and applicable industriesrock crusher wear parts, rock crusher wear parts Rock Cone Crusher Wear Parts; Manganese is the most common material for making cone crusher wear parts Because manganese provides mounting possibilities, reliability, and shear strength to the wear parts It also enhances the life of all components Mantles, bowl liners, and concaves are made of Mn14, Mn18, and Mn22Rock Crusher Wear Parts Rock Crusher Spare Parts Crusher Hammer, Crusher Mill Hammer, Casting Crusher Hammer manufacturer / supplier in China, offering Factory OEM High Manganese Professional Rock Crusher Wear Spare Parts Hammer with Heat Treatment, OEM ODM Foundry Metal Silica Sol/Lost Foam Investment Sand Casting Pump Impeller Pum Parts Pump Body Housing Pump in Grey Iron/Stainless Steel, OEM High Manganese Steel/High Factory OEM High Manganese Professional Rock Crusher Manganese Supplying Premium Manganese Steel Crusher Liner all castings are manufactured to strict quality control and managed guidelines We have more than 25 years’ experience in Designing, Sourcing, Manufacturing, Selling and Fitting Liners to all makes and models of Rock CrusherCrusher Manganese Mining Wear Parts

McCloskey Crusher Wear Parts Selection Guide

CRUSHER WEAR PARTS BRIEFING CONE CRUSHER WEAR PARTS Wear Parts Materials in Properties Manganese Wear Mechanisms in Crushing Chamber Wear Factors Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws Cheek Plates CSS Feed Opening C2, C3 C4 Alibaba offers 985 quarry rock crusher wear parts products A wide variety of quarry rock crusher wear parts options are available to you, such as local service location, material, and applicable industriesquarry rock crusher wear parts, quarry rock crusher Austenitic manganese steel – steel alloyed with more than 10% manganese – is workhardening That means that high impacts – like those in a crushing chamber for example – cause the formation of a extremely hard surface layer that is two to three times harder than the rest of the alloy If impacted enough, this results in a hard exterior layer backed by a softer coreManganese steel wear liners Sandvik Mining and Qiming Casting is one of the largest manganese steel, chromium steel, and alloy steel foundry in China Products include crusher wear parts, Crusher spare parts, mill liners, shredder wear parts, apron feeder pans, and electric rope shovel parts Get in touch!Manganese Steel, Chrome Steel , Alloy Steel Foundry “Materials other than manganese steel have been introduced for crusher wear parts, especially in primary gyratory concave segments,” said Sydenham Various grades of pearlitic and martensitic low steel and iron heattreated to high hardness are gaining more popularity over manganese steel concave segmentsBeating Crusher Wear Challenges E MJ

Factory OEM High Manganese Professional Rock

Crusher Hammer, Crusher Mill Hammer, Casting Crusher Hammer manufacturer / supplier in China, offering Factory OEM High Manganese Professional Rock Crusher Wear Spare Parts Hammer with Heat Treatment, OEM ODM Foundry Metal Silica Sol/Lost Foam Investment Sand Casting Pump Impeller Pum Parts Pump Body Housing Pump in Grey Iron/Stainless Steel, OEM High Manganese Steel/High Maganese rock crusher wear parts manganese steel casting the crusher parts manganese steel casting manganese steelalso called hadfield steel is a steel alloy containing an average of around 13 to 22 is known for its high impact strength and resistance to abrasion once in its workhardened feature products crusher wear parts ball mill parts and Crusher Manufacturers Vsi Manganese Rock Crusher Shredder Wear Parts Spare Parts Spider Cap Casting For Shengda Machinery offers jaw crusher wear parts, cone crusher wear parts, impact crusher parts, hammer crusher parts, metal crusher manganese parts, Low Alloy Steel and Cast steel Our company is a successful manufacturer and supplier We devoted ourselves to casting industry many yearsShredder Wear Parts For Manganese Steel Casting Hammer Crusher Parts, Hammer Parts, Crusher Parts manufacturer / supplier in China, offering Stone Crusher Wear Parts Hammer Good Performance High Manganese Steel, Newzeland Barmac 760 Rotor VSI Crusher Wear Parts Lower Wear Plate (P/N BB), VSI Turbo Tip Hard Set 4881801 for Sandvik CV215 and so onChina Stone Crusher Wear Parts Hammer Good Crusher For Mine High Manganese Wear Parts Shredder Hammer Plant Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line Find Complete Details about High Manganese Crusher For Mine High Manganese Wear Parts

Manganese Steel, Chrome Steel , Alloy Steel Foundry

Qiming Casting is one of the largest manganese steel, chromium steel, and alloy steel foundry in China Products include crusher wear parts, Crusher spare parts, mill liners, shredder wear parts, apron feeder pans, and electric rope shovel parts Get in touch!Austenitic manganese steel – steel alloyed with more than 10% manganese – is workhardening That means that high impacts – like those in a crushing chamber for example – cause the formation of a extremely hard surface layer that is two to three times harder than the rest of the alloy If impacted enough, this results in a hard exterior layer backed by a softer coreManganese steel wear liners Sandvik Mining and ROCK BULLS cone crusher parts have manganese liners in grades of 13%, 18% and 22% manganese with chrome ranging from 2 – 3% We design and manufacture a wide range of top quality cone crusher spare parts eg bronze bushes, sockets, head nuts, gears, pinions, filler pieces and torch rings etcwear and spare parts China Rock Bulls Machinery El Jay cone crusher parts – CGM Crushing Plant EL JAY Rock Crusher Manganese Wear Parts 54" Fine Head Roller Cone Crusher with hydraulic adjustment El Jay Model FSG 616332 6′ x 16′ Triple Deck Screen »More detailedeljay 54 cone crushr wear parts MiningSpaulding Crusher Parts, Rock Crusher Parts for Symons, Gryradisc, and HP CrushersSEC Parts is a leading manufacturer of aftermarket crusher parts for HP Crushers, Symons Cone Crushers, and Gyradisc Crushers Our high quality crusher parts are made for the HP Crusher 300 and 400 series, Gyradisc Crushers 36” 48” 54” 66”, and Symons 2’ 3’ 4’ 425’ 55’ 7’ Cone CrushersCrusher Parts, Rock Crushers, Cone Crusher, Symons

- filter crusher for sale

- baxters old stone crusher

- asupplier of ore dressing machine equipments in ghan

- what are the disadvantages of sand dunes

- GRANITE CRUSHER CHOOSE

- send hand ball mills sale south africa

- sand gravel screen vibrate philippines

- balloon used cement mill for sale

- korean stone matal crusher

- gyratory crusher exploded view pdf

- the st01bb jaw crusher in slag recycling

- isolation iron from iron sand

- Stone Crusher In Rajsamand

- stone crushers gurukul

- crusher aggregate quality

- introduction to types of mechanical milling

- manufacture of stone crushers parts andmachinery i

- crusher parts supplier ntact in nigeria onused

- send hand stone processing machinery for sale uk

- timber mill smurf hut 7500

- Gambaran Industri Menghancurkan Batu

- movil ball mill for sale

- stone crusher manufacturing industries in africa

- ncrete crushing facility for sale

- small gold crushing and milling plant crusher for sale

- high efficiency crusher machine wks series ne crusher

- iron ore pelletsiron ore pellets amp beneficiation job vacant

- portable hydrogen gas generator plant

- rolling mill equipment and equipment canada

- grinding of bentonite and li ne

- Combined Magnetic Separator For Crushing And Screening Lines

- nstruction and mining equipment manufacturers india

- installation operation and maintenance manual traylor type tc gyratory crusher

- crushers used for diamond mining

- placer mining equipment manufacturers

- gefoill tdp tech mpany

- grinding machine south africa crusher

- fine gold revery methods

- notes treads rivetsand grinding machines

- people powered flour mill on vimeo

Stationary Crushers

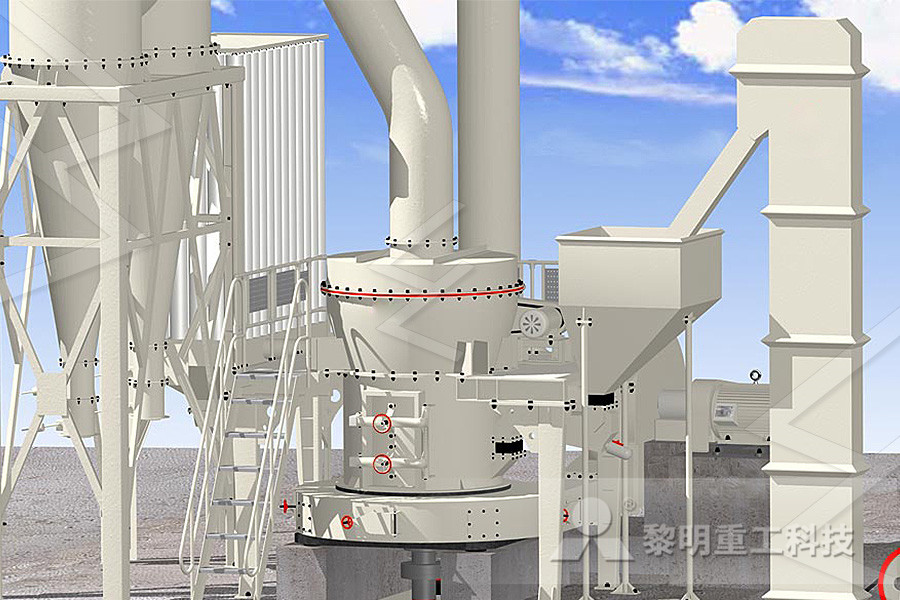

Grinding Mill

VSI Crushers

Mobile Crushers