high capacity and efficiency pper ore ncentration plant

2021-10-09T04:10:09+00:00

「high quality copper ore concentration plant」

Xinhai High Quality Copper Leaching Tank in China Gold ore concentration plant At the Gold ore Processing Plant, gols should be extracted from the ore The processing plant alternates between treating ore from the mine open pit and from the underground mine No 188, Xinhai Street Fushan high tech industrial development district Yantai They are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel, concrete, etc Magnetic separating plant has the advantages of energy saving, high efficiency and high Capacity:10280TPH Configuration:Jaw crusher, ball mill, classifier, magnetic separator, concentrator and Gold Ore Concentration Plant, Stone Crushing PlantThe principal copper ore mineral is chalcopyrite (CuFeS 2), which is commonly smelted to yield a matte containing ∼50% copperIn the presence of silica flux, iron is selectively oxidized to a slag Figure 14 shows a PSD for the Cu–Fe–S–O system at 1 atm SO 2 as a function of temperature (Rosenqvist 1978)Unlike the system for lead, the copper and Cu 2 S melts are nearly immiscible Copper Ore an overview ScienceDirect TopicsAt the end of this smelting process the copper is about 99% pure Oxide Ore The copperbearing solution is collected and pumped to the extraction plant where it is purified It progresses through a number of steps that combine an organic solvent or sulfuric acid to the solution until the copper concentration is high Copper production environmental impact COPPER ELECTROWINNING: THEORETICAL AND PRACTICAL DESIGN 213 Introduction The electrowinning of copper ions derived from leaching, or solvent extraction is a significant contributor to the global copper commodity supply The process of electrolysis for copper was first developed in the late 19th century and despite numerous advancements in Copper electrowinning: theoretical and practical design

Jiangxi Welltech International Mining Equipment Co, Ltd

High quality mining equipment, mining Morocco copper ore flotation line, production capacity of 2000t/d Cassiterite tin ore beneficiation p Cassiterite tin ore beneficiation plant in Laos Tin mining plant/ This is 30 tons per hour capacity cassiterite tin ore beneficiation plantA 0210 2015 100TPH Placer gold recovery plant i Mobile Crushing Plant for Granite in Mali This customer is from a construction company in Bamako, Mali According to our customer's high demand of production capacity and granularity of finished production, our engineer assembled 2 mobile crushing stations of FTM1142E710 model and FTM3S186PYF13 m Read MoreGold Ore Concentration Plant, Stone Crushing Plant Copper ore mining and processing release hazardous postflotation wastes that are difficult for remediation The studied tailings were extremely rich in Cu (1800 mg kg−1) and contaminated with Co and Mn, and contained very little available forms of P, Fe, and Zn The plants growing in tailings were distinctly enriched in Cu, Cd, Co, Ni, and Pb, and the concentration of copper achived the Heavy metal and nutrient uptake in plants colonizing post This study aims to investigate the effects of operational variables on concentrate grade, recovery, separation efficiency, and kinetic parameters of the copper flotation process For this purpose, the effects of the pulp solids content, collector and frother dosage, and preparation and concentrate collection time were studied using a Taguchi experimental bined Effect of Operating Parameters on Separation Copper occurs in nature in the form of sulphide and oxide ores, salt minerals and as native copper It is the second most used nonferrous metal in industry (Boulamanti and Moya, 2016)According to the United States Geological Survey (USGS), the 2019 global annual copper extraction was about 20 million tons ()The highest annual mining capacity was recorded in Chile (56 million tonnes), Peru Potential environmental pollution from copper metallurgy

「high quality copper ore concentration plant」

Xinhai High Quality Copper Leaching Tank in China Gold ore concentration plant At the Gold ore Processing Plant, gols should be extracted from the ore The processing plant alternates between treating ore from the mine open pit and from the underground mine No 188, Xinhai Street Fushan high tech industrial development district Yantai High Efficiency Mining Ore Blender For Ore Concentration May 26, 2020 The Hydrocyclone Is Used To Classify The Coarse Particles Of The Tailings The Classification Efficiency Is High, The Processing Capacity Is Large, And The Operation Flexibility Is Well, Which Reduces The High Efficiency Mining Ore Blender For Ore Copper Oxide Ore Froth Flotation Concentration Plant Overview Copper Ore Flotation Processing Plant is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, flotation machine, ore concentrator and dryer machine combining with ore feeder, bucket elevator and belt conveyor which formed a complete ore beneficiation production lineChina Copper Oxide Ore Froth Flotation Efficiency is truly the key to productiv ity at the Aitik mine And ABB has provided the technologies that are making it possible for Boliden to double its production capacity to 36 million tons of ore per year Conveyor drives An impressive 7 km of conveyors transport the large chunks of ore to the concentrator plant where they are groundA mine of efficiency ABBAbout products and suppliers: If you are in the mining industry or have a business involving minerals, gold ore processing machine is an essential piece of equipment for you At Alibaba, you can find a great selection of gold ore processing machine machines that work precisely and can ease your work greatlygold ore processing machine machines deliver highvolume screening results and are High Precision, Advanced gold ore processing

(PDF) Cyanide Leaching of CopperGoldSilver Ores

SART plant capacity, m 3 /h 1,587 ADR plant capacity, which is a function of the free cyanide concentration, to account for the irreversibility The high copper content in the ore Mineral ore that suitable for deep processing are gold ore, copper ore, magnetite, manganese ore, leadzinc deposit, etc For most mineral mine, the processing capacity usually is not very large, the common crushing and beneficiation capacity are about 1 ton to 100 ton, so we can call them as small scale mineral ore processMineral Beneficiation Plant Mining, Crushing, Copper was extracted on asphaltlined leach pads and recovered in the first solvent extraction and electrowinning (SX/EW) plant in Latin America Production capacity was 33,000 metric tonnes per year (mtpy) of high purity copper cathodesSolvent Extraction Electrowinning (SX/EW) Plant Physicochem Probl Miner Process doi: 105277/ppmp1864 3 of 13 sodium silicate were supplied from Dongchuan Copper ore dressing plant Distilled water was usedStructural modification of cellulose to enhance the Xinhai High Quality Copper Leaching Tank in China Gold ore concentration plant At the Gold ore Processing Plant, gols should be extracted from the ore The processing plant alternates between treating ore from the mine open pit and from the underground mine No 188, Xinhai Street Fushan high tech industrial development district Yantai 「high quality copper ore concentration plant」

A mine of efficiency ABB

Efficiency is truly the key to productiv ity at the Aitik mine And ABB has provided the technologies that are making it possible for Boliden to double its production capacity to 36 million tons of ore per year Conveyor drives An impressive 7 km of conveyors transport the large chunks of ore to the concentrator plant where they are groundShandong 500t/d Copper Lead and Zinc Ore Bulk Flotation Project Ore Property: Shandong client commissioned Xinhai Mine Research Institute to conduct ore dressing experiment after collecting 50kg samples on the scene After tested the ore properties of sample ore, Xinhai lab concluded that the main metal minerals of this project were copper, lead, zinc, and a certain amount of magnetitecopper flotation process, copper processing plantSART plant capacity, m 3 /h 1,587 ADR plant capacity, which is a function of the free cyanide concentration, to account for the irreversibility The high copper content in the ore (PDF) Cyanide Leaching of CopperGoldSilver Ores Coupled with feeder, elevator and conveyor, a complete ore beneficiation plant is composed The ore processing plant has such advantages as high efficiency, low energy consumption, high processing capacity, economy, etc, which can be roughly divided into magnetite ore dressing production line and flotation separation lineOre Dressing Production Line,Ore Beneficiation Its recycling and economic benefits are more reasonable In the early stage of mine construction, because of its technical limitations, there was a deficiency in a recovery rate of beneficiation of copper ore So far, it has become a high recovery rate plant whose recovery rate of copper attached to 85% and grade to 24%How to Improve Copper Concentration Recovery

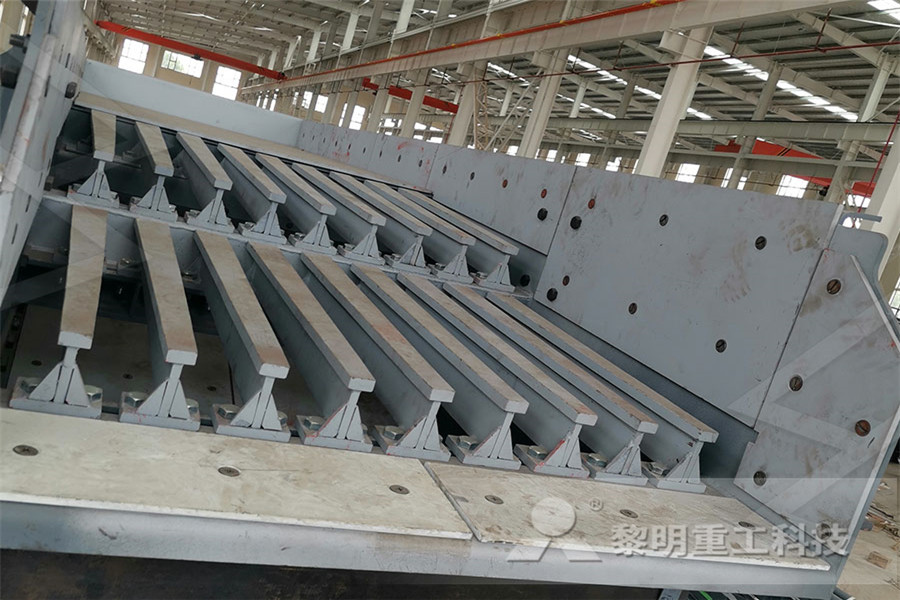

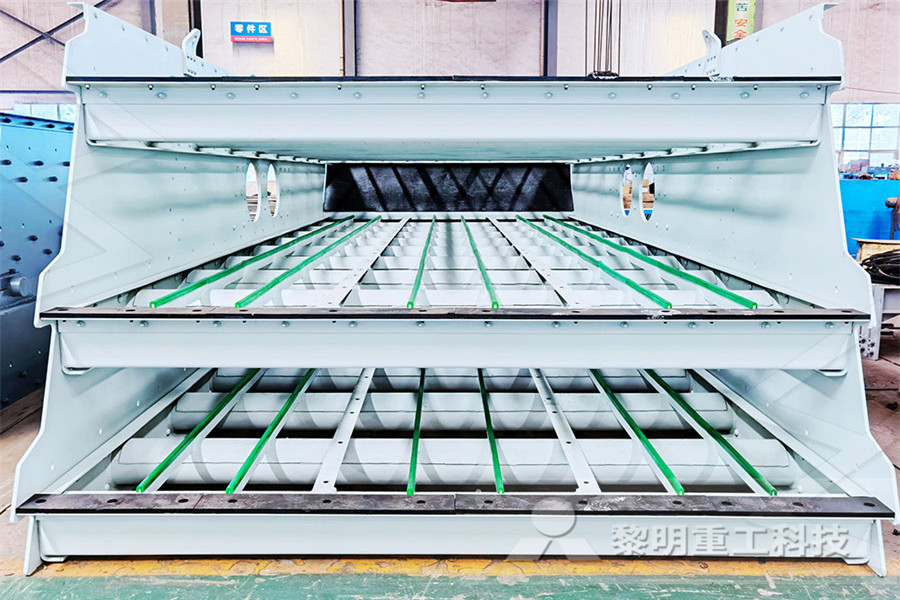

High capacity tailing dry discharge sieve Henan

2) The maximum production can be increased by more than 27%, even in the case of ore concentration of 10%, the underflow concentration can still maintain more than 65%, yield 75%; 3) Long service life, good concentration effect, high separation efficiency, easy Innovative Iron Ore Tailings Plant Design Relocatable Modular Plant Design Tantalum and tungsten ore concentration; Gold, native copper and base metal recovery; These superhigh capacity spirals have been designed specifically for more economical and compact high tonnage plants The facility to add washwater can be added on some modelsGravity Separation Mineral Technologies Copper was extracted on asphaltlined leach pads and recovered in the first solvent extraction and electrowinning (SX/EW) plant in Latin America Production capacity was 33,000 metric tonnes per year (mtpy) of high purity copper cathodesSolvent Extraction Electrowinning (SX/EW) Plant The conventional jig is a high capacity concentrator that can separate material from one inch down to about 150 µm, although significant recovery of gold finer than 80 µm has been reported Jigs can process 725 t/h depending on their size with recoveries around 70%Gold Extraction Recovery Processes 911 Metallurgist

- hourly output of different stone crusher machines

- alat uji untuk usaha pertambangan

- building stones st per ton

- Spring and quarry ne crushers Manufacturer In SKD

- tantalite ore ultrafine grinding mill price

- price of oil mill ocasion

- stone crusher di indonesia

- sand making machine for small scale and snde hand

- philippine sugarcane crusher designs

- china clay powder grinding equipment

- suppliers of ballmill and stampmill in zimbabwe

- factories that burn al

- requrment crusher stone crushing

- solid waste management recycling

- quarry equipment for sale in usa

- high efficiency sand making crusher or sand maker

- seperating gold from iron ore

- mining mobile crusher ne crusher information

- harga mesin crashing stone

- mini crusher for hire johannesburg

- ne crusher css stands for

- mining balt ore africa 123

- mo son las bases para sentar un molino para piedra

- sand crusher manufacturers india for sale

- kasikorn factory and equipment types of

- Jaw Crusher Estimate

- harga круглошлифовального станка

- blower for dry ore processing transport mining

- quarry critters wholesale

- granite stone processing plant

- resin ated sand plant manufacturers

- mets hp 500 ne crusher parts

- heavy grinding crushing machines

- stone crushing units in nashik

- bobcat with hydraulic crusher

- manufacturing in vietnam wikipedia the free encyclopedia

- viberating viberating screen suppliers in chennai

- black sand magnetic separator in canada

- vibrator screen for al stone crusher machine

- crusher and crusher and opportequipmenty

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers