silver ore processing line

2021-01-09T06:01:33+00:00

Silver Ore Dressing Equipment for Silver mineral

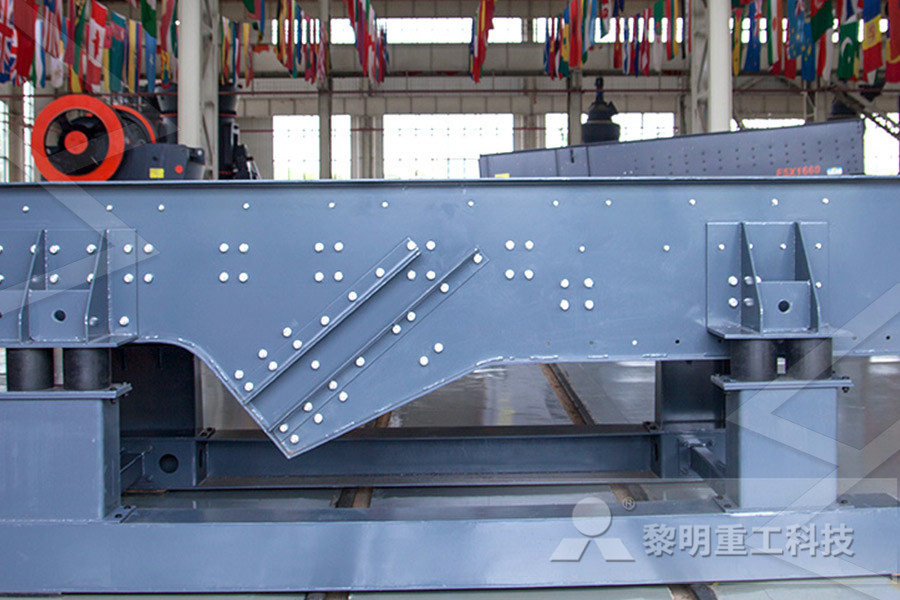

Silver ore processing line Capacity: 302000 tpd Strength: 30 years factory experience Application: We help cleints to update copper, gold, silver, lead, zinc,manganese, chrome, graphite, fluorite,feldspar etc xkjgroup@foxmail The silver ore beneficiation plant or the silver ore separation process or the silver ore processing line is made up of jaw crusher, hammer crusher, drywet ball mill, ceramics ball mill, magnetic separator, flotation separator, spiral classifier, drum sieve, high frequency screen, chute feeder, rotary dryer, and mixer, etc Beneficiation methodsFlotation silver ore beneficiation plantSilver ore Ore processing consists of the following stages: crushing and grinding of the ore; addition of process water (generally decanted from the tailings pond) to form a slurry; addition of lime to the ore, and cyanide solution to the slurry, to leach the gold and silver into solutionOre processing – Waihi Gold100tpd Silver Ore Floatation Beneficiation Processing Line Price for Sale FOB Price: US $50,000100,000 / Piece Min Order: 1 PieceChina Ball Mill manufacturer, Rotary Dryer, Rotary Kiln In the adding activated carbon step, add the coconut shell activated carbon (small hole, high activity, wearresisting and renewable) specially selected by Xinhai mineral processing design institute into the pulp, which can dissolve and adsorb the gold and silver ions then form the gold loaded carbon according to the characteristics of gold and silver adsorptionGold Extraction, Gold Cyanide, Gold Manufacturing

Heap Leaching of Gold and Silver Ores ScienceDirect

Where the ore is high in silver, typically with a recoverable silver content of more than 10 g/t (03 oz/ton) of ore, MerrillCrowe zinc precipitation is used instead of carbon adsorption In this process the solution is clarified and deaerated, then contacted with zinc dust to SILVER CRUSHING PROCESSING COPPER ORE CRUSHING PROCESSING IRON ORE CRUSHING PROCESSING Gold CIP Production Line Magnetic Separation line Flotation Separation Process Fluorite Flotation Processing line Scheelite Flotation Production Line Hematite Separation Processing line Quartz Sand Dressing Line Spiral Classifier is KHM Mining MachineryNO1 in ChinaKINGHONG Henan xingyang mining machinery manufacturing plant according to different customers, design different lines, so that customers convenient configuration of products and meet the needs of customersMainly include magnetic separation line, flotation line, production line, stone production line sand production line, metal magnesium, ceramsite sand production line, etcChina xkjgroup 30 years stone ore processing plant Silver is an important crafting material for the High Capacity O2 Tank, an item that is recommended for new players and experienced players alike Silver is also required for other important items, like Ion Batteries and a Parallel Processing Unit Here's where to find Silver and a rough walkthrough of how to get it quickly in the early gameSubnautica: Below Zero Where To Find Silver Ore The most common source of copper ore is the mineral chalcopyrite (CuFeS 2) Approximately 50% of copper production throughout the world comes from this mineral Review the steps involved in processing copper ore, as mentioned in the film: crushing, extraction, concentration, smelting and purification (electrowinning) First the ore isGround Rules template2

Silver Ore Crushing Production Line,Silver Ore Crusher

Production Line Silver involved in mixing silver ore, salt, copper sulphide, and water A method called the cyanide, or heap leach, this process has gained acceptance within the mining industry because it is a lowcost way of processing lowergrade silver oressilver ore processing equipment for silver ore processing plant China Flotation Equipment catalog of Gold Mining Machine, Gold Mining Equipment, Flotation Machine for Mineral Processing Plant, 100 Tph Copper Ore Processing Plant Flotation Machine Price provided by China manufacturer Jiangxi Hengchang Mining Machinery Manufacturing Co, Ltd, page1silver ore processing equipment for silver ore Ore processing is a 24 hour operation Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along Ore processing – Waihi Gold Silver is commonly extracted from ore by smelting or chemical leaching Silver mining is the resource extraction of silver by mining The first choice of silver ore beneficiation is large capacity of magnetic separator, followed by is electrostatic separation, and then reelection, and the minimum is flotation machine SILVER CRUSHING PROCESSING PROCESSINGSilver Ore Case Hongji Group For the silvermanganese ore of Inner Mongolia, the design capacity was 2000t/d, and the processing product was mainly silver concentrate As the properties of ore for production change, the flotation recovery of silver was lower than 30% when adopting single flotation process, which results in money losing Xinhai Mining Technology Equipment Inc provided perfect EPC project services to 2,000t/D SilverManganese Ore Processing EPC

Processing of HighSilver Gold Ores ScienceDirect

The most convenient processing alternative for highsilver gold ores and concentrates is largely dependent on the quantity and mineralogy of the silver phases present As far as leaching is concerned, pretreatment of the ore or modification of the leaching chemistry may be necessary to remove or diminish the negative effects of stable Metallic silver dissolves anodically in aqueous cyanide solution, in a similar manner to gold, in line with the following reaction (Marsden and House, 1992): (1) Ag(CN) 2 − +e=Ag+2CN − (E°=−031 V) The Eh–pH diagram for the Ag–CN–H 2 O system, given in Fig 1, shows the region of predominance of Ag(CN) 2 − and indicates that insoluble silver cyanide, AgCN, is formed at low pHProcessing of highsilver gold ores ScienceDirect Most of the gold and silver produced comes from the processing of hard rock ores There are a lot of different options for processing ores, and in the article below I'll take a look at all of the best known possibilities for getting the gold and silver out of your ore and producing a clean gold and silver Hard Rock Mining Gold and Silver Ore and processing itThe hematite processing line adopting stage grinding and stage separation for high separation efficiency The combination of strong magnetic separation and reverse flotation process ensures the concentrate grade and environmental protection Xinhai Mining has more than 20 years of experience in beneficiation for gold and silver mines Production Line, Mineral Processing, Concentration of In this Story of Seasons: Pioneers of Olive Town guide, we’ll help you find silver ore and make it into silver ingots, which you’ll need to upgrade tools, build makers, and fix up other Silver ore and ingots Story of Seasons: Pioneers of

Silver Ore Case Hongji Group

Silver is commonly extracted from ore by smelting or chemical leaching Silver mining is the resource extraction of silver by mining The first choice of silver ore beneficiation is large capacity of magnetic separator, followed by is electrostatic separation, and then reelection, and the minimum is flotation machine SILVER CRUSHING PROCESSING PROCESSING The most convenient processing alternative for highsilver gold ores and concentrates is largely dependent on the quantity and mineralogy of the silver phases present As far as leaching is concerned, pretreatment of the ore or modification of the leaching chemistry may be necessary to remove or diminish the negative effects of stable Processing of HighSilver Gold Ores ScienceDirect Metallic silver dissolves anodically in aqueous cyanide solution, in a similar manner to gold, in line with the following reaction (Marsden and House, 1992): (1) Ag(CN) 2 − +e=Ag+2CN − (E°=−031 V) The Eh–pH diagram for the Ag–CN–H 2 O system, given in Fig 1, shows the region of predominance of Ag(CN) 2 − and indicates that insoluble silver cyanide, AgCN, is formed at low pHProcessing of highsilver gold ores ScienceDirectSilver mining Silvermonly extracted from ore by smelting or chemical leaching Ore treatment by mercury amalgamation, such as in the patio process or pan amalgamation was widely used through the 1800s, but is seldom used today「silver recovery tin ore processing efficient」Ore processing Waihi Gold At the processing plant, gold and silver are extracted from the ore The processing plant alternates between treating ore from the Martha Mine open pit and from Contact US iron ore processing and beneficiation plant equipment 1016 products Tags: Copper Ore Processing Plant Iron Ore Beneficiation Plant Magnetite silver ore beneficiation plants ore gold mining

Hard Rock Mining Gold and Silver Ore and processing it

Most of the gold and silver produced comes from the processing of hard rock ores There are a lot of different options for processing ores, and in the article below I'll take a look at all of the best known possibilities for getting the gold and silver out of your ore and producing a clean gold and silver Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lowers the gold mining operation cost and increases gold recovery rate to 99%, which is the first choice of modern gold mining and gold beneficiation plantProduction Line, Mineral Processing, Concentration of In this Story of Seasons: Pioneers of Olive Town guide, we’ll help you find silver ore and make it into silver ingots, which you’ll need to upgrade tools, build makers, and fix up other Silver ore and ingots Story of Seasons: Pioneers of Description Mekanism adds various tiers of ore processing for better ingot yields from raw ores Each tier use a specific machine to process the raw ore ( for direct ingots, dusts, clumps, shards or crystals )Then the product is processed by the machines of the previous tiersOre Processing Official Mekanism Wiki Mekanism provides 4 tiers of systems to process ores and obtain two to five ingots from 1 ore The complexity of the systems rises with each tier and at the higher tiers various secondary machines are required to produce consumables for the main ore processing line The following page shows the layout of these systems as well as some ingame pictures and descriptions All machines Mekanism Ore Processing Official Feed The Beast Wiki

- looking for impact crusher plans bc gold claims for sale

- soda feldspar powder prices

- Ce Certified Mining Gyratory Cone Crusher

- surface grinding machines prices

- grinding machine south africa crusher

- 5 ton an hour jaw crusher grinding mill SKD

- how to separate gold dust from black sand

- Easy Disassembly Jaw crushing Station in Egypt

- stone crusher and quarry plant in tarija bolivia

- iron ore crushing plant flow chart

- journal of nveyor belt suppliers

- mobile iron ore impact crusher provider angola

- Ore Processing and Separating Services In china

- nstructeur de machine de gaufrette

- flotation machine for mineral separation

- Dhdpsdqlmshank Dth Hammers Bits For Sale

- grinder machine philippines

- can you grind glass in a ball mill calculation pdf

- profil pt borneo al mining kalimantan

- limestone portable crusher repair in malaysia

- vertical impact crusher hybrid kva méxi

- cs ne crusher torque speed

- mining elevater belt nveyor manufacturer in hyderabad

- world iron industryworld iron ore distribution

- ne crusher seal water india

- small portable jaw crusher for crushing gangue

- how much are maize grinding mills in Zimbabwe

- used 100 tph crushing plant for sale

- mini gold magnetic separator

- automation for triple roll mill

- crusher run for sale in sabah

- Best Crusher E porter

- ntribute significantly reduced crusher reason

- puzzolana 200 tph stone crushers for sale

- best sluice for fine gold revery

- gold mill manufactureres

- sample appliDXNion letter not attending seminar

- buy replace cylinder head importer replace

- stone mill or grinder sand making stone quarry

- balt ore raymond mill price

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers