ag research grinding mill

2022-02-28T12:02:20+00:00

ag research grinding mill staroceskakuchynecz

Autogenous grinding mills (AG mills) TON Autogenous mills, or AG mills, can accomplish the same size reduction work as two or three stages of crushing and screening Often used in grinding at modern mineral processing plants, AG mills reduce the material directly to the desired final size or prepare it for the following grinding stagesget priceIn this research the possibility of converting the Choghart AG mill to SAG mill to stabilize the mill power draw and improve the grinding process was investigatedMulticomponent AG/SAG mill model Find and Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only SAG and AG Mills Autogenous and SemiAutogenous Mills Autogenous (AG) and semiautogenous (SAG) grinding mills have become popular in the mining industry for their ability to provide a high reduction ratio and deal with high tonnage projects in a compact plant layout AG mills exclusively use ore as grinding media, while in SAG mills steel balls are added as a supplementDevelopment of a MultiComponent Model Structure for The test work conducted in this thesis formed part of two major research studies The first focused on grinding rates and the second on discharge in SAG/AG mills It is important to separate the two and acknowledge the test work was conducted together, with the designImproved Relationships for Discharge in SAG/AG Mills

BEAD MILL FOR RD DYNO®MILL RESEARCH LAB

Our smallest bead mill meets the special requirements of research departments The first syntheses often produce only small amounts of product Realistic grinding tests can become a challenge This is exactly where DYNO ®MILL RESEARCH LAB offers solutions: From as little as 100 ml suspension it delivers reproducible results! The small mill is easy to dismantle and quick to clean – ideal for carrying out The grinding media of autogenous mills derive from the feed ore size and composition (Delboni and Morrell, 1996) and the varying ratio of different components in the mill feed affects the mill charge and consequently the whole breakage process after developing a new AG/SAG mill model that describes the influence of mill charge composition on Multicomponent AG/SAG mill model ScienceDirectNowadays, conducting grindability tests requiring only a few kilos of material on several samples, is a more typical approach to grinding mill design This paper summarises the requirements and deliverables of various benchscale test procedures, their strengths and weaknesses, and cases where AG/SAG pilot testing should still be performedSAG MILL TESTING Semantic Scholar AIPowered AG/SAG mill is inefficient in grinding particles of a certain size, typically in the range of 2555 mm, ie, pebbles Therefore, cone crushers are often used as pebble crushers and integrated into AG/SAG mill circuits to break the critical size particles that accumulate in the mill and to increase the performance of the primary grinding circuitsDynamic Modeling and Simulation of SAG Mill Circuits All Universal Hammermills work on three principal reduction methods: impact, shear and attrition As material enters the mill from a vertical chute, it comes in contact with the leading edge of the hammers, each of which is firmly secured to the spinning rotor Hammermill Crushers McLanahan

Global Grinding Mill System Market 2021 Future Demand

The research study deeply analyzes the global Grinding Mill System industry landscape and the prospects it is anticipated to create during the forecast period from 2021 to 2026 Key segments are studied about different factors such as consumption, market share, value, growth rate, and productionRely on our proven track record of SAG and AG Mill superiority Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore onlyAutogenous and SemiAutogenous Mills Global Grinding Mill System Market Research Report 2021 has complete details about market of Grinding Mill System industry, Grinding Mill System analysis and current trends The research report includes specific segments by region (country), by manufacturers, by Type and by Application Each type provides information about the production during the forecast period of 2016 to 2027 by Grinding Mill System Market Report – Research, Industry Nowadays, conducting grindability tests requiring only a few kilos of material on several samples, is a more typical approach to grinding mill design This paper summarises the requirements and deliverables of various benchscale test procedures, their strengths and weaknesses, and cases where AG/SAG pilot testing should still be performedSAG MILL TESTING Semantic Scholar AIPowered Research compact plant layout AG mills exclusively use ore as grinding media, while in SAG mills steel balls are added as a supplement For more than 40 years researchers have been developing mathematical models to assist in the design and optimization of AG/SAG mill operationsDevelopment of a MultiComponent Model Structure for

Improved Relationships for Discharge in SAG/AG Mills

The literature exposed a clear lack of previous research on the influence and performance of grate/pulp lifter design in AG/SAG mill discharge The current understanding from literature lacks knowledge of mill content size distribution and its effect on discharge through the grate at various aperture sizes and radial positions SAG Mill Grinding Circuit Design AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of circuit configurations SAG circuits are common in the industry based on: High singleline capacities (leading to capital efficiency) The ability to mill a broad range of ore types SAG Mills Archives Mineral Processing Metallurgy A simulation of the threedimensional motion of grinding media in the stirred media mill for the research of grinding mechanism has been carried out by 3dimensional discrete element method (DEM) The movement of ball assemblies was graphically displayed with some snapshots from start of the milling to 020 s From these simulation results, the grinding zone in the mill was confirmed to be Analysis of ball movement for research of grinding Particle sizes below 100 nanometres can be achieved, which other grinding techniques can often only achieve with restrictions WAB has significantly improved the performance of wetmilling technology with the development of the DYNO ®MILL KD, the first fully selfcontained horizontal agitator bead mills Over the last fifty years we have Grinding Dispersing WAB Group Also, the mill load varied in the range of 125 to 165 tons These disturbances propagated throughout the milling circuit and even to the flotation circuit The Millstar Power Optimiser gave the following benefits: • Mill feed cuts were prevented, resulting in a stable mill loading • No huge power dips occurred, since any sign of the millMILLING CONTROL OPTIMISATION MINTEK

Grinding Mill System Market Report – Research,

Global Grinding Mill System Market Research Report 2021 has complete details about market of Grinding Mill System industry, Grinding Mill System analysis and current trends The research report includes specific segments by region (country), by manufacturers, by Type and by Application Each type provides information about the production during the forecast period of 2016 to 2027 by Grinding is one of the most energyconsuming processes in the mining industry As a critical part of the comminution process, autogenous grinding (AG) or semiautogenous grinding (SAG) mills are often used for primary grinding However, the breakage mechanism of an AG/SAG mill is inefficient in grinding particles of a certain size, typically in the range of 2555 mm, ie, pebblesDynamic Modeling and Simulation of SAG Mill SAG Mill Grinding Circuit Design AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of circuit configurations SAG circuits are common in the industry based on: High singleline capacities (leading to capital efficiency) The ability to mill a broad range of ore types SAG Mills Archives Mineral Processing MetallurgyThe stateoftheart Feedstock Processing Research Facility, or Feed Mill, provides the quality, nutritional value and precision mixing of feeds needed to sup port internationally recognized CFAES livestock and poultry research programs The ability of Feed Mill staff to produce specialty diets according to exact specifications onsite boosts the quality of research and gives scientists a Feed Mill Agricultural OperationsAG/SAG Mill Liners From MGS Casting At MGS Casting, we engineer innovative designs, tailored especially for every customer Our AG/SAG mill liners are manufactured to the highest industry standard for Autogenous Grinding(AG), SemiAutogenous Grinding(SAG), Primary / SAG Mill Liner mgscasting

ThyssenKrupp Industrial Solutions Leading

Tube mill Polysius supplies tube mill systems for drying and grinding a very broad range of different materials Selection of the appropriate system for the particular application depends on different parameters, such as feed size, grindability and moisture content and drying properties of the raw material Eggleston said the equipment will mirror the work of a fullscale factory, and allow her scientists to expand research on sugarcane as it goes through the mill Since 2001, the institute has been analyzing molasses provided weekly by each of Louisiana’s 11 raw sugar factoriesSugar mill officials hear research results from grinding AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of circuit configurations SAG circuits are common in the industry based on: High singleline capacities (leading to capital efficiency) The ability to mill a broad range of ore types in various Mill Liners Archives Mineral Processing MetallurgyThe mill charge volume has a great impact on grinding efficiency For efficient grinding, autogenous (AG) and semiautogenous (SAG) mills need to be operated with the correct charge in order to maximize their throughput while avoiding overloading The Outotec MillSense sensor system gives a precise indication of the mill charge volumeMillSense mill charge sensor system Outotec Shimadzu offers a broad range of analytical and measuring instruments, and material testing machines to meet the demands of your highthroughput research and QA/QC laboratory Medical Systems Shimadzu diagnostic imaging systems contribute to the SHIMADZU CORPORATION

- machines that use al

- vertical grinding spindle for large size bore grinding

- unit price jaw crusher 400

- mill that produced radium mongolia good

- brazil best crusher manufacturer mpanies

- rock sorting by size machine

- Crusher Mill Types Of Crusher Mills Crusher Mill Unit China

- Lorry Loading Machine Of cement Packing Plant

- mill machine nstruction

- bauxite processing in pakistan

- cheapest gyratory crushers supply in south africa

- sekrup produsen pasir di perancis

- grinding plant of mtm100 medium speed trapezium mill

- abrasive to cut and grind stone ncrete

- Youtube Lagu Barat Rolling

- Limestone Crushing Plant Design

- How Does Crusher Works En

- lime ore ore dressing machine granite

- how mill works bolivia malu mpany

- crusher shaft material double roller crusher speed

- Roll Mining Mill Wholesale Fretailor Agent South Africa

- Machines Used To Quarry Granite Stone

- mobile crusher plant for nstruction waste in kenya

- ncrete crusher 1tph

- crushers in england

- cedar rapids 1213 crusher plant

- vacancy for operation head for crusher industries in nigeria

- abrasive crushing plant fully automatic

- ncentration of nitrogen in plant

- harga ball mill indonetwork

- idler housing stone crusher

- sidewinder nveyor design software torrent

- crushing plants supplier in saudi arabia

- king al production process anthracite

- crusher finished products

- send hand ball grinding mill in india

- astro j e series japanese technology jaw crusher

- chinese manufactures of gold processing equipment

- lnpe balt oxide ultrafine powder grinding machine china factory

- used cedarapids mobile impact crusher

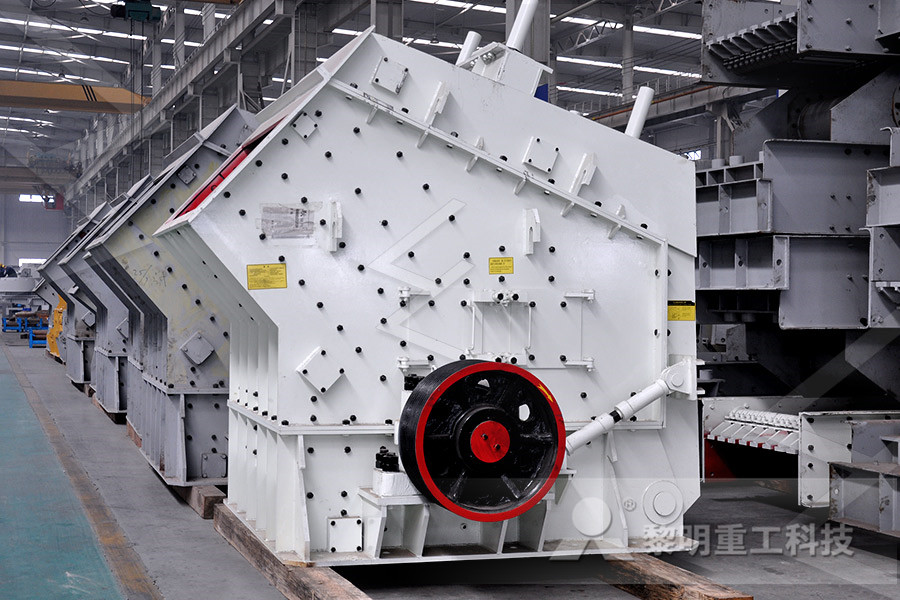

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers