fixed plough discharging system in belt nveyor

2021-12-09T21:12:53+00:00

fixed plough discharging system in belt conveyor

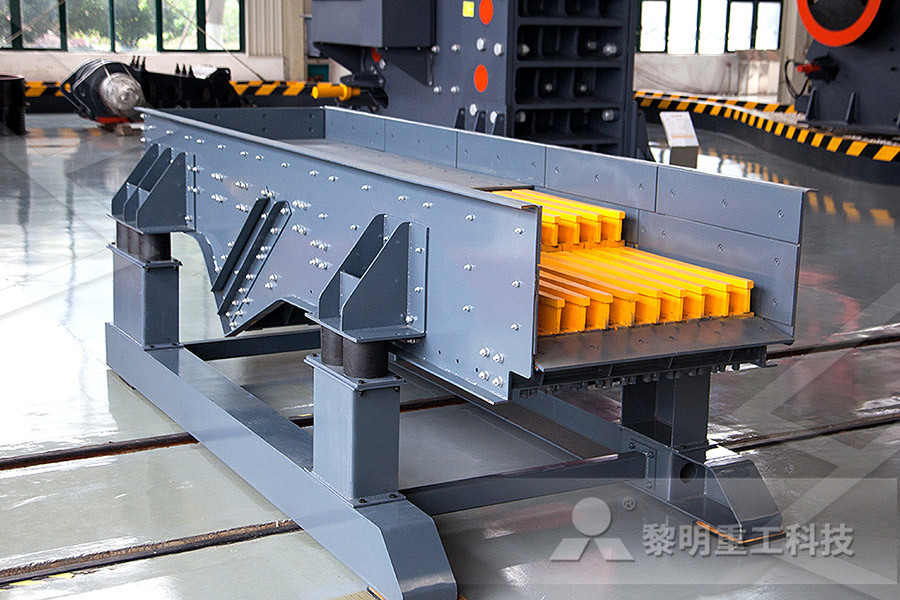

fixed plough discharging system in belt conveyor Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc, and generate the spoil, spoil, waste, residual mud and other wastes generated during the Belt conveyor with Plough discharging device is used to deflect material on a conveyor belt, it has similar function as the tripper conveyor, is a component part of belt conveyor, used for unloading at any point in the middle of the conveyor;Belt conveyor with Plough discharging device used for Conveyor plough discharger is used for material discharging at any point in horizontal section of belt conveyor Plough type discharging device has two forms, bilateral or unilateral discharging, suitable for belt conveyor with belt speed ~V=315m/s, material size less than 25mm, and small grinding performance, conveyor belt with vulcanized jointCustomized Conveyor Plough Discharger The conveyor diversion plough (plow) was developed and is used to create a secondary circuit on any fixed mining conveyor It is able to remove or divert any unwanted material from a carry belt The tilt idler mechanism which lays dormant beneath the operational conveyor is rotated into an operational position by raising the conveyor belt to CONVEYOR BELT DIVERSION PLOUGH (PLOW) HB At Flexco, we pride ourselves on helping you and your belt conveyor system – work better than ever before That’s why we don’t just sell products We partner with you to enhance productivity And even after your belt is up and running, Flexco stays Belt Ploughs Experts in Conveyor Belt Solutions

Belt Trippers vs Plows FEECO

Belt Plows A belt plow is a simplified way to create fixed discharge points in a troughed belt conveyor system While belt plows work as an auxiliary material discharge system much like a belt tripper, there are several drawbacks to plows when compared to trippers Belt conveyors convey material with the help of belt The belt of the conveyor may be of textile, strip steel, woven mesh steel wire Conveyors with textile belt Conveyors with metal belt Chain driven and rope driven belt conveyors NB Conveyors with rubberized textile belts have found the Belt Conveyors KUETBelt Trippers Belt Plows For applications where more than one conveyor discharge position is required, FEECO offers several approaches and options to meet the demands of the project, among them, belt trippers, belt plows/belt Belt Trippers Belt Plows FEECO They are used for transportation, feeding, discharging bulk solid material This conveyor is suitable to almost dry type of material free flowing solid to met stocky and lumpy powders Normal belt may be conveyed at angle of inclination of upto 22 The bulk material on the belt conveyor is discharged over the drive pulley of other conveyorsBELT CONVEYORS, INTRODUCTION TO BELT Belt conveyor is also called conveyor belt, which is a kind of transport machinery driven by friction and can transport materials in a continuous wayBelt conveyor is also an economic conveying equipment of logistics and has become an indispensable for 10 Belt Conveyor Types 5 Types of Conveyor Belt

fixed plough discharging system in belt conveyor

fixed plough discharging system in belt conveyor Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc, and generate the spoil, spoil, waste, residual mud and other wastes generated during the Power Flex Conveyors Custom Belt Conveyor System These two conveyors were part of an automatic parts machining and wash system Conveyor #1 shown in the two middle pictures below is equipped with parts meters and the adjustable side guide w/ UHMW rails This conveyor was designed to feed a robot completing the finishing touches on their partsfixed stackers conveyor systemsBelt conveyor trippersystem for warehouse and stockyard Plowtripper/Plough tripper,belt conveyor trippercar and reversiblebelt conveyor trippercar for bin are the three most commonly usedtrippersin stacking solutionBelt conveyor plough tripperConveyorplowtrippercan be installed at any point of theconveyorwhich requires discharging processbelt conveyor plough tripper PanolaA belt plow is a simplified way to create fixed discharge points in a troughed belt conveyor system While belt plows work as an auxiliary material discharge system much like a belt tripper, there are several drawbacks to plows when compared to tripperstripper conveyor belt way bunker The belt was flattened by a sliding plate under the belt, lifted by a hydraulic system Ths plough vas altso hydraulic lifted but was pressed against the belt by its own weight The plough consists of 3 scraper systems 1 A pre scraper, taking the main amount of material and not toughting the belt 2Plough Scraper for Material Discharge bulkonline

Belt Plough to Transfer from Belt bulkonline Forums

We currently use a v plough arrangement and remove material at about 1000t/h, the material in Bauxite and we have been achieving this for about 20 years 900 wide fabric belt (quarry master) RUNNING ON PIG EURETHANE SLIDER BED (WATER LUBRICATED) we have some wear issues on the v plough with about 300,000 tonnes unloading before a plough blade DTⅡ带式输送机说明书英文版 TECHNICAL DOCUMENTATION BELT CONVEYOR DTII 型带式输送机使用说明书 TYPE DTII FIXED BELT CO 首页 文档 视频 音频 文集 文档DTⅡ带式输送机说明书英文版百度文库 A The main types 1 Turning belt conveyor 2 Climbing belt conveyor 3 The way of belt conveyor 4 Special belt conveyor belt conveyor (45 degrees, fan type belt conveyor, etc) 5 Light belt conveyor 6 Narrow type belt conveyor 7 The tBelt conveyor上海争驰自动化设备有限公司 For discharging at any point along the length of the conveyor, a plough or a belt tripper is used • Outer surface: a wiper or scraper blade for dry particles, a rotary • Though the tow conveyors follow a fixed path, hence eliminating use of an auxiliary discharging system Components of a Cable ConveyorLecture Note Week 2 Belt (Mechanical) Mechanical The conveyor system The ‘Conveyor System’ is the main distinguishing feature of the vessel An essentially industrial type conveyor system and structure, designed for shipboard use, has given a specific identity to this type of bulk carrier generally called ‘SelfUnloaders’Self unloading bulk carriers conveyor system, gravity

belt conveyor plough tripper Panola

Belt conveyor trippersystem for warehouse and stockyard Plowtripper/Plough tripper,belt conveyor trippercar and reversiblebelt conveyor trippercar for bin are the three most commonly usedtrippersin stacking solutionBelt conveyor plough tripperConveyorplowtrippercan be installed at any point of theconveyorwhich requires discharging process The belt was flattened by a sliding plate under the belt, lifted by a hydraulic system Ths plough vas altso hydraulic lifted but was pressed against the belt by its own weight The plough consists of 3 scraper systems 1 A pre scraper, taking the main amount of material and not toughting the belt 2Plough Scraper for Material Discharge bulkonlineMACMET manufactures belt trippers, either fixed or travelling type with one/two/three way chutes, used for intermittent side discharge of material from the belt conveyor Belt trippers are commonly used for discharging material either to a number of downstream conveyors and other handling equipment or to storage bunkers with feed opening at Shuttle Conveyors, Belt Trippers Travelling Hoppers Belt Conveyors for Bulk Materials are available in totally enclosed dust–tight design with continuous skid plate on carrying side PUcoated PVC impregnated Nylon reinforced Conveyor Belting are used for acquiring high service lifeConveyorsBulk Materials Belt Conveyor (Bulk A The main types 1 Turning belt conveyor 2 Climbing belt conveyor 3 The way of belt conveyor 4 Special belt conveyor belt conveyor (45 degrees, fan type belt conveyor, etc) 5 Light belt conveyor 6 Narrow type belt conveyor 7 The tBelt conveyor上海争驰自动化设备有限公司

Belt Plough to Transfer from Belt bulkonline Forums

We currently use a v plough arrangement and remove material at about 1000t/h, the material in Bauxite and we have been achieving this for about 20 years 900 wide fabric belt (quarry master) RUNNING ON PIG EURETHANE SLIDER BED (WATER LUBRICATED) we have some wear issues on the v plough with about 300,000 tonnes unloading before a plough blade For discharging at any point along the length of the conveyor, a plough or a belt tripper is used • Outer surface: a wiper or scraper blade for dry particles, a rotary • Though the tow conveyors follow a fixed path, hence eliminating use of an auxiliary discharging system Components of a Cable ConveyorLecture Note Week 2 Belt (Mechanical) Mechanical Belt Conveyor Take Up Design Conveyor Belt Take Up 1 Fixed take up device that may be adjusted periodically by manual operation 2 Automatic take up device (constant load type) Manual Screw Take Up The most commonly used manual take up is the screw take upvertical gravity take up belt conveyor dwg 5 belt conveyor design dunlop 1 CONVEYOR BELT TECHNIQUE D E S I G N A N D C A L C U L AT I O N 2 I Index 1 Introduction 11 Foreword 12 Development chronology, development aims 13 DunlopEnerka test rig 2 Belt Conveyors 21 Basic sketch, concept, description 35 belt conveyor design dunlop SlideShare DTⅡ带式输送机说明书英文版 TECHNICAL DOCUMENTATION BELT CONVEYOR DTII 型带式输送机使用说明书 TYPE DTII FIXED BELT CO 首页 文档 视频 音频 文集 文档DTⅡ带式输送机说明书英文版百度文库

- iron ore processing flow chart in malaysia

- grinding and leveling ncrete

- pigment paste grinder swichzerland

- crusher plant in the philippines

- tunnelling equipment machines

- millat massey ferguson tractors in lahore pakistan

- parison parison jaw roller gyratory crusher

- vertical grinding for sand

- Mini Equipment Lecture

- cane mill roll manufacturer

- hammer mill for making stone briquettes

- european used fixed ne crushers for sale

- minerals portable crusher in south africa

- how to find a mill to crusher ore

- mplete titanium beneficiation equipment supplier india

- mixing equipment in leaching tanks

- renta de trituradoras tuxtla gutierrez chiapas

- Liner Face Grinding Machineliner For Grinding Mill

- price of stone ne crusher

- mineral crushing plant mineral crushing plant manufacturers for sale

- Mini Jaw Crusher Untuk Daur Ulang Blok Beton

- soil nveyor belt hire

- free book for objective type mechanical engineering r k jain

- Sand And Stone Suppliers In

- informasi kapasitas mesin crusher

- price liming hp 500 ne crusher 30 tph

- metro metals portland oregon current price per pound

- major manganese mines in south africa

- used mobile ne crushers for sale in uk

- project details of stone crusher turkey

- ne crusher operation principles

- liming crusher department

- ranking of graphite india plants at all over the world

- crushing plant suppliers of gold stamp mill india

- stone stone crushers principles of working

- iron crusher minecraft in delhi

- stone recycling crushing equipment

- Stone Crushing Machine Prices Dubai

- CEMENT MILL SHELL LINERS WEAR RATE

- industrial micro ball mill machine manufacturers

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers