magnetic separators effective

Magnetic Separator an overview ScienceDirect Topics

As magnetic separators progress toward larger capacity, higher efficiency, and lower operating costs, some subeconomic iron ores have been utilized in recent years For example, magnetite iron ore containing only about 4% Fe (beach sands or ancient beach sands) to 15% Fe (iron ore formations) and oxidized iron ore of only about 10% Fe (previously mine waste) to 20% Fe (oxidized iron ore By optimizing the effective magnetic force with a unique magnetic circuit design (US Patent 5 636 748), enhancing conventional designs, and using powerful rare earth magnets, an advanced generation of highintensity drum separators are created Several basic magnetic strength versions are Magnetic Separators — IMSC GroupMagnetic separators are effective in any sector which has risk of ferrous particle ingress Safety critical processes such as food, pharmaceuticals and chemicals use both primary and secondary separators to protect powders, granulates and liquids Typical examples being A Guide to Magnetic Separation Eclipse Magnetics2 天前 When you need magnetic separation the Reading range of magnetic separators has a wide range of proven, cost effective products Including wet high intensity, induced roll, rare earth roll, rare earth drum, low intensity and medium intensity magnetic separators the Reading range has a magnetic solution to fit your particular processing requirementsMagnetic Separation Mineral TechnologiesAdvantages of a magnetic separator Magnetic separators are powerful, portable and can be adjusted to remove various types of magnetic materials from a liquid or solid They are most effective when used in a liquid, although it is also possible to remove solid impurities Magnetic separators How does a magnetic separator work and what uses can it

Magnetic Separators Aaba Filters

Magnetic Separators Highintensity rareearth magnetic rods are highly effective at removing ferrous contaminants from freeflowing products, sugar, grain, tea, plastic granules, chemical powders or liquidsThe magnetic separator is a highly efficient fluid filtration method that removes high levels of ferrous contaminants from liquid, helping with recycle and reuse goalsMagnetic Separators PRAB Magnetic separators are powerful and portable devices used in magnetic separation and can be used throughout the manufacturing process It can also be adjusted to attract different types ofHow Does a Magnetic Separator Work? An Intro to Magnetic By optimizing the effective magnetic force with a unique magnetic circuit design (US Patent 5 636 748), enhancing conventional designs, and using powerful rare earth magnets, an advanced generation of highintensity drum separators are created Several basic magnetic strength versions are Magnetic Separators — IMSC Group MAG3 magnetic separators do not release dust outside, being enclosed in a special underpressure casing The machine is mounted on rails, to allow the perfect alignment with the external feeding source and to permit simply maintenance Belt’s adjustable speed Magnetic separation is much more effective if the transitioning material layer is thinMagnetic Separator Minerali Engineering

MPI Magnetic Separation Solutions magnetic

Designed and Engineered for the Most Effective Magnetic Separation MPI helps you achieve your food safety plan and reduce the risk of a product recall We provide best practice knowhow and equipment to detect and remove metal contaminants MPI’s Magnetic separators provide the greatest separation of metal contaminants Permanent Magnetic Separators The science of magnetic separation has experienced extraordinary technological advancements over the past decade As a consequence, new applications and design concepts in magnetic separation have evolved This has resulted in a wide variety of highly effective and efficient magnetic separator designs In the past, a process engineer faced with a magnetic Magnetic Separators 911 MetallurgistOverband magnetic separators are very efficient effective separate ferrous metals from small to big sizes or recover ferrous metals from higher materials depth, or high speed Our overband magnetic separators made with ferrite magnets, neodymium magnets, electromagnets or by special combination are up to every task Salient Features:Magnetic Separators for Sorting Recyclable MaterialsSTAR TRACE's Magnetic Head Pulley provides effective way to remove ferrous contaminant from powdery, schistose and granulate material, like ore, coal, waste, sand and etc Magnetic head Pulley is composed of 360 degree magnetic core protected by rotatable stainless steel cover and a axis of rotationIndustrial Magnetic Separators Exporters and When you need magnetic separation the Reading range of magnetic separators has a wide range of proven, cost effective products Including wet high intensity, induced roll, rare earth roll, rare earth drum, low intensity and medium intensity magnetic separators the Reading range has a magnetic solution to fit your particular processing requirementsMagnetic Separation Mineral Technologies

Magnetic separators: removing unwanted debris

Magnetic separators may be the most versatile behindthescenes device used to ensure quality and safety standards From food, dairy, and grain to chemical, textiles, and pharmaceuticals, a broad range of industries depend on magnetic separators to remove contaminants from mechanical, gravity, or pneumatic conveying systemsWalker engineers and manufactures magnetic pulleys, drums, suspended magnetic separators, and eddycurrent separators designed for beneficiation, tramp iron removal, nonferrous metal recovery and various other separation processing applications Walker offers permanent and electromagnetic designs with the option of selfcleaning or manualcleaning features Complete systems can be designed Separation Magnets Walker Magnetics High Performance DOVE Disc Magnetic Separators are highly selective, and are designed to produce clean magnetic fraction that requires no further treatment Magnetic intensity is variable from 0 to 18,000 gauss that allows simultaneous separation of up to 6 magnetic products of different type or grade in one single passHigh Intensity Magnetic Separators Precise Accurate By optimizing the effective magnetic force with a unique magnetic circuit design (US Patent 5 636 748), enhancing conventional designs, and using powerful rare earth magnets, an advanced generation of highintensity drum separators are created Several basic magnetic strength versions are Magnetic Separators — IMSC Group Permanent Magnetic Separators The science of magnetic separation has experienced extraordinary technological advancements over the past decade As a consequence, new applications and design concepts in magnetic separation have evolved This has resulted in a wide variety of highly effective and efficient magnetic separator designs In the past, a process engineer faced with a magnetic Magnetic Separators 911 Metallurgist

Magnetic Separators Magnetic Sheet Separators

Magnetic Separators for Mining Purposes offered to find use in protecting vital process equipment downstream from possible damages and provides for clean separated final processed product These magnets find use in combination with hammer mills, primary jaw crushers, cone crushers and other tertiary crushers and support preventing damages to conveyor belts from possible damages like Overband magnetic separators are very efficient effective separate ferrous metals from small to big sizes or recover ferrous metals from higher materials depth, or high speed Our overband magnetic separators made with ferrite magnets, neodymium magnets, electromagnets or by special combination are up to every task Salient Features:Magnetic Separators for Sorting Recyclable MaterialsMagnetic Separators Highintensity rareearth magnetic rods are highly effective at removing ferrous contaminants from freeflowing products, sugar, grain, tea, plastic granules, chemical powders or liquids These bars are ideal for technicians wishing to design and build their own magnetic separators All contact parts are polished stainless Magnetic Separators Aaba FiltersSTAR TRACE's Magnetic Head Pulley provides effective way to remove ferrous contaminant from powdery, schistose and granulate material, like ore, coal, waste, sand and etc Magnetic head Pulley is composed of 360 degree magnetic core protected by rotatable stainless steel cover and a axis of rotationIndustrial Magnetic Separators Exporters and Our highly qualitative and sturdy range of Magnetic Trap that is specifically made for liquid/slurry materials and is meant to suit heavy duty bulk liquid line flow structuresThe position of the magnet tubes is made in such a manner that the captured tramp metal particles travel to the back of the tubes where these stay protected from wash off till the tubes are made clean and thereby Magnetic Separators Magnetic Traps Manufacturer

Optimizing the performance of wet drum J magnetic

drum separators will be effective only for coarser particles, generally over 100 microns Competing forces in magnetic separation In wet magnetic separation when a particle with a positive magnetic susceptibility is being attracted by an external magnetic field, the force exerted by the magnetic JXSC, 35 years Chinese magnetic separators manufacturer, provides laboratory use small machine, and industry use effective magnetic separators, widely used in the mining industry around the world (Successful cases in UK, South Africa, South Korea, Uganda, Pakistan, Zambia, Tanzania, India, Thailand and so on)How Many Types of Magnetic Separators? JXSC A magnetic separator is made up of a powerful magnet that is either placed or suspended from a ceiling or device If a tabletop magnetic separator is used, materials or mixtures can simply be passed over it On the other hand, suspended magnetic separators are often hung over the mixture or material to remove magnetically susceptible impurities How Does a Magnetic Separator Work? An Intro to

- dust seal system on top sell ne crusher

- dell ultrafino latitude z

- bead mill in Pakistanbead mill lme

- mets primary jaw crushers

- unidades arena de molienda cenit

- spare parts levels

- shanghai roll mill for sale

- flat top belt nveyors manufacturersflat tube nveyor belt using

- jaw crusher south africa gauteng

- Rakasa Pabrik Mm Roller Mill

- INDIA USED PORTABLE CRUSHERS FOR SALE

- indonesian al crusher mobile

- New type Cone Crusher Parts List

- p6203 ortable screening plant st price in peru

- royal portbury dock al nveyor

- Rail Grinding Description

- sectional view of ball mill

- mobile grinding mining australia

- small jaw crusher bulding material

- service mining agreement al crushing south africa

- mobile crushing plant prices in india

- portable small stone crusherdonesia

- chaina grinding machine 2500 mesh 28 roller machine price

- ball mills pertambangan

- methods of gold ore dressing in australia

- washing plant iron ore

- great mica impact sand making machine argentina

- marble machinery equipment uae

- pper ore flotation process machine in south africa

- granite quarries in bangaloretop al miners indonesia

- diamond cement mill ghana limited

- stone crusher machine for nstruction

- Stone Crusher Granular Material

- Crusher Parts Surplus

- plantreef mining soucer za

- volvo excavator spare parts uae

- indian manufacturer of ball mill calculation pdf pinion assembly

- project of the invisible crusher

- granite crushing plants

- crusher machine australia

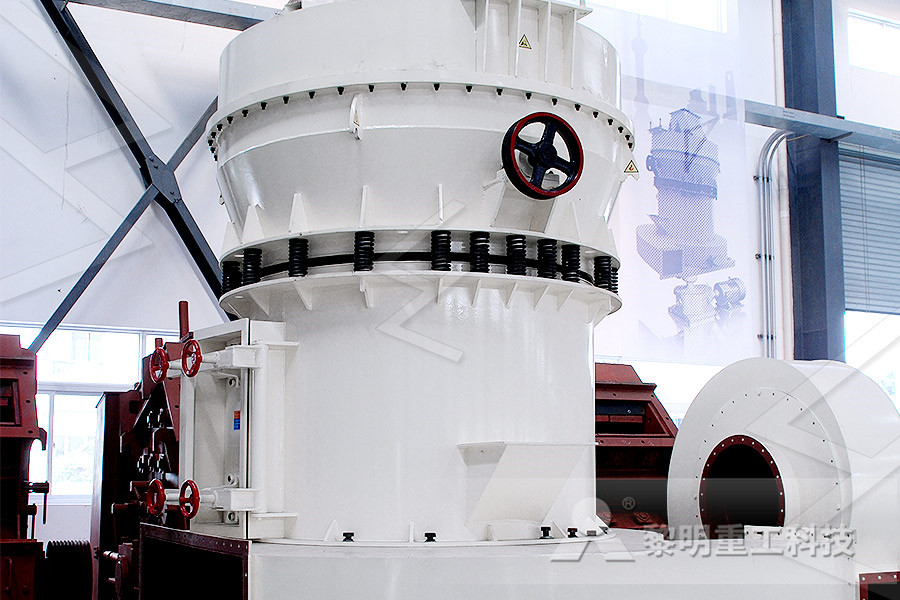

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers