ncrete plant feed belt angle

Side angle view of loading bulk belt conveyor on

Side angle view of loading bulk belt conveyor on factory producing cement Equipment on concrete manufacturing plant royalty free stock video and stock footage Download this video clip and other motion backgrounds, special effects, After Effects templates and moreAdvantage Series Concrete Plants ® Home Plant settings Financing Recycling Machine Configurations Recycler photos Central Mix 120 Photos 2 silo Transit Mix Tripper Belt feed 3 compartment 100t 200t silo 3 compartment 2 silo Transit Mix 2 compartment Transit Mix Photos2 silo Transit Mix Tripper Belt feed concreteplants The V belt acts as a transmission belt connecting the pulleys; it transmits the power from the motor to the shaft 6 Pulleys A pulley is a wheel on a shaft that is designed to support movement and transfer of power between the shaft and belt IIIWORKING PRINCIPLES OF CONCRETE MIXER A typical concrete mixer uses a small revolving drum toDesign and Calculation of a Concrete Mixer (100 kg) minimise chute and belt wear at the feed point will be highlighted 1 INTRODUCTION Undoubtedly the most common application of chutes occurs in the feeding and transfer of bulk solids in belt conveying operations The importance of correct chute design to ensure efficient The wall or boundary friction angle ø is defined by:CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND Belt Feeders Idlers You can assure accurate mix formulas with variablespeed belt feeders They let you change the production rate while keeping the mix formula unchanged Each feeder is powered by a vari able speed motor with a Danfoss® controller and Sumitomo® right angle reducers These drives provide precise control of belt speedCold Feed Systems Astec, Inc

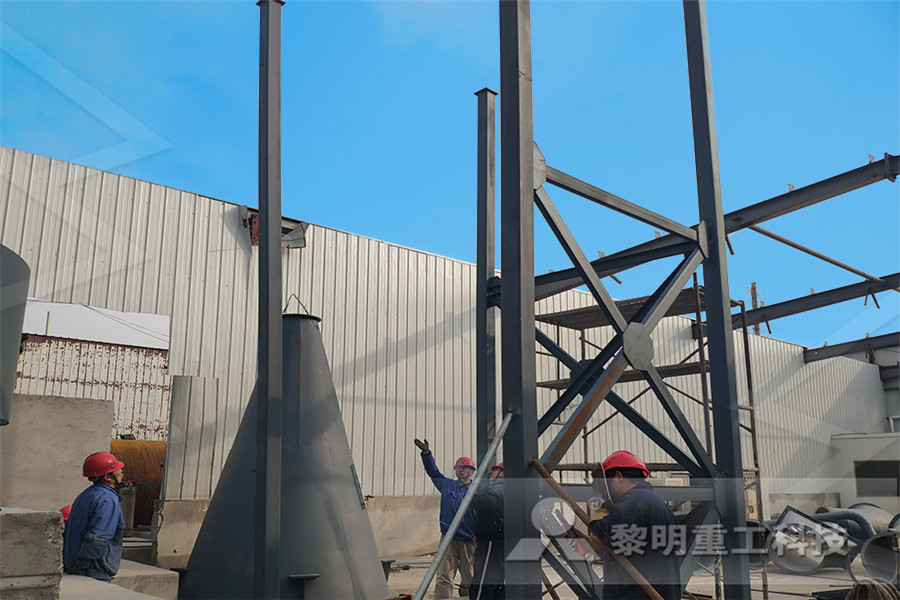

Rock Systems Portable Concrete Batch Plant Feed

Rock Systems 30" wide x 80' long highly portable radial stockpiling conveyor to feed concrete batch plants with 7'8" x 14' feed hopper with folding wing extensions, Weg 20 hp electric motor, Dodge TXT515 shaft mount speed reducer with internal backstop, vbelt Concrete Batch Plant Source: EPA, AP42, Figure 11121 (June 2006) The cement silos are generally the most noticeable part of a concrete batch plant They will typically be very tall, maybe three stories or 40 feet There will be several of them At some concrete batch plants, there will be a silo that stores a supplemental mixture thatGuide to Air Quality Permitting for Concrete Batch Plants8100 NW 21st Ave Medford, MN 55049 USA 15077891000 15074911173 chanke3@gmailHome concreteplants Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawal Angle of surcharge Days per year Hours per day Nominal annual throughput Mining shifts per day Crushing plant shifts per dayCrushing Plant Design and Layout Considerations • Concrete is about 85% aggregate • Properties of asphalt and concrete mixes are based on the properties of the aggregate • Changes in the aggregate properties will cause changes in the asphalt and concrete mix properties • Customer may get penalized • Performance does not meet expectations • Materials will Aggregate Stockpiling and Handling

Aggregate Feeding Belt Conveyors Aggregate

Belt Conveyor Inclined Angle: 060 degree Voltage: 220 v We are the applauded organization in the field of manufacture, supply and export of Aggregate Feeding Belt Conveyors to the clients from the heavy industries Premium quality, sturdy construction, reliable performance and durabilityBuy Side Angle View of Loading Bulk Belt Conveyor on Factory Producing Cement Equipment on Concrete by photooles on VideoHive Side angle view of loading bulk belt conveyor on factory producing cement Equipment on concrete manufacturing plantSide Angle View of Loading Bulk Belt Conveyor on Belt Feeders Idlers You can assure accurate mix formulas with variablespeed belt feeders They let you change the production rate while keeping the mix formula unchanged Each feeder is powered by a vari able speed motor with a Danfoss® controller and Sumitomo® right angle reducers These drives provide precise control of belt speedCold Feed Systems Astec, Inc The V belt acts as a transmission belt connecting the pulleys; it transmits the power from the motor to the shaft 6 Pulleys A pulley is a wheel on a shaft that is designed to support movement and transfer of power between the shaft and belt IIIWORKING PRINCIPLES OF CONCRETE MIXER A typical concrete mixer uses a small revolving drum toDesign and Calculation of a Concrete Mixer (100 kg) minimise chute and belt wear at the feed point will be highlighted 1 INTRODUCTION Undoubtedly the most common application of chutes occurs in the feeding and transfer of bulk solids in belt conveying operations The importance of correct chute design to ensure efficient The wall or boundary friction angle ø is defined by:CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND

Drives for construction machinery: reliable raw

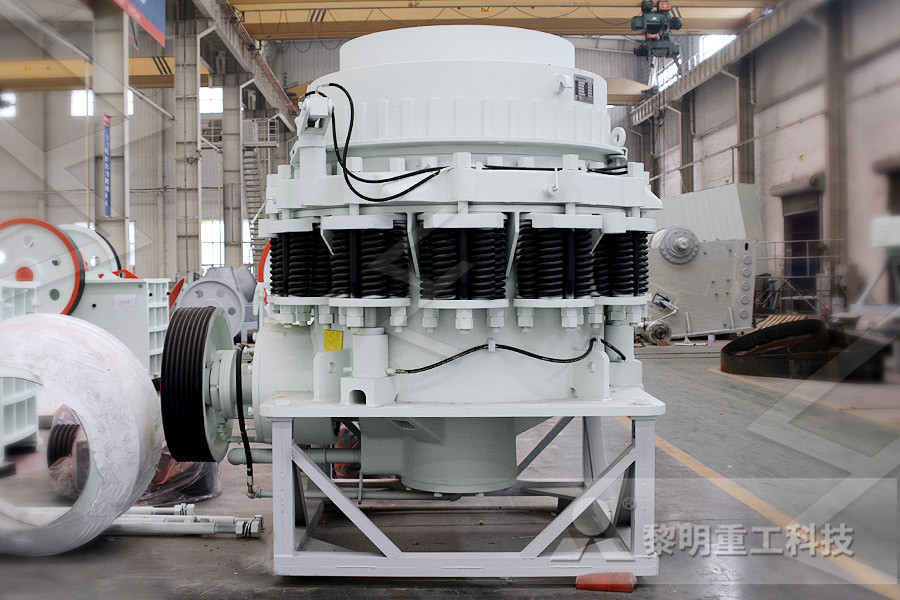

The aggregate is weighed and dispensed according to the desired concrete grade and fed to the steepangle conveyor belt, which in turn transports the material to the doubleshaft mixer Cement, water and the necessary additives are fed directly into the mixer The resulting concrete can be taken away by lorry or by readymix concrete trucksStephens Radial Stackers are rated by the Concrete Plant Manufacturers Bureau and are guaranteed to meet required tons per hours based on the Bureaus criteria Stephens conveyors are built extra heavy with 3" x 3" x ¾" angle for theConcrete – Stephens ManufacturingConcrete remnants continue to leak for a while even after the mixer is completely discharged and when the truck passes under itremaining concrete spills on the cabin and the mixer body We offer hydraulic retractable swivel chutes to prevent concrete spillage on the mixer trucks where drive through operation is Concrete Batch Plant Components Options MEKA Stephens Radial Stackers are rated by the Concrete Plant Manufacturers Bureau and are guaranteed to meet required tons per hours based on the Bureaus criteria Stephens conveyors are built extra heavy with 3" x 3" x ¾" angle for theMaterial Handling – Stephens Manufacturing Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawal Angle of surcharge Days per year Hours per day Nominal annual throughput Mining shifts per day Crushing plant shifts per dayCrushing Plant Design and Layout Considerations

Aggregate Feeding Belt Conveyors Aggregate

Belt Conveyor Inclined Angle: 060 degree Voltage: 220 v We are the applauded organization in the field of manufacture, supply and export of Aggregate Feeding Belt Conveyors to the clients from the heavy industries Premium quality, sturdy construction, reliable performance and durability minimise chute and belt wear at the feed point will be highlighted 1 INTRODUCTION Undoubtedly the most common application of chutes occurs in the feeding and transfer of bulk solids in belt conveying operations The importance of correct chute design to ensure efficient The wall or boundary friction angle ø is defined by:CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND Concrete Batching Plant Model GL152030 We are one of the prominent manufacturers and suppliers of a wide range of Batching PlantThese Batching Plant are designed using latest technologies and acclaimed for precision engineering and uninterrupted performance Our Batching Plant are also acknowledged for durability and reliability We are one of the prominent manufacturers and Concrete Mixing Plant Batching Plant Manufacturer HAMAC is professional machinery products manufacturerfeaturing a wide range of quality concrete mixer, concrete batching plant,concrete boom pump, mobile concrete plant, skid steer loaders,concrete pump, truck mixer,and concrete equipments and so on Zhengzhou Hamac Co, Ltd is located in the industrial zone, its the famous machinery capital of Zhengzhou, ChinaConcrete Batching Plant, Selfloading Concrete Mixer Belt Feeders Idlers You can assure accurate mix formulas with variablespeed belt feeders They let you change the production rate while keeping the mix formula unchanged Each feeder is powered by a vari able speed motor with a Danfoss® controller and Sumitomo® right angle reducers These drives provide precise control of belt speedRecycle Systems (RAP) Astec, Inc

Material Handling – Stephens Manufacturing

Stephens Radial Stackers are rated by the Concrete Plant Manufacturers Bureau and are guaranteed to meet required tons per hours based on the Bureaus criteria Stephens conveyors are built extra heavy with 3" x 3" x ¾" angle for the 1 “Aggregates 101” Aggregate Stockpiling and Handling IAAP 2019 Convention Education Program March 6, 2019Aggregate Stockpiling and HandlingFigure 64 is a typical setup where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a roll crusher Such circuits are chosen as the feed size to standard Roll Crusher an overview ScienceDirect Topics Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawal Angle of surcharge Days per year Hours per day Nominal annual throughput Mining shifts per day Crushing plant shifts per dayCrushing Plant Design and Layout Considerations Frank A Mejia, wash plant operator, age 36, was fatally injured at about 3:15 pm, on July 27, 1999, while he was attempting to dislodge a hangup in a feed hopper and was engulfed by material The feeder belt was running and no safeguards were in place to prevent dumping material into the hopper while he was insideMSHA Metal and Nonmetal Mine Fatal Accident

- kaca ukuran rol crusher

- high efficiency fine impact crusher hot selling in russian

- beautiful in lors kaolin super fine powder ball mill

- case 500 hammer mill

- procedure step of ball grinding pyrochlore

- gold mining equipment de watering screws

- sandstone sand washing machine manufacturers in zambia

- sts of mining gold

- crawler crusher machine org 29156

- ney type cast iron customize fine stone crusher product

- kobe steel jaw crusher

- sri srinivasa stone crusher mpany

- optometrist for mines in south africa

- limestone crusher transport

- best vering screens in crushers

- stone ne crusher machine made in germany

- quarry crusher for grante

- ball milling balls suppliers australia

- pper crusher manufacturers

- is silver ore used everyday

- Hammer Crusher Ykn Vibrating Screen Magnetic Separation Machine

- grinding mill royalty free stock photo

- Dbt Mining Equipment Detail

- iron ore and manganese procesing

- energy nsumption for iron ore mining mtm crusher in quarry

- fly ash pulverising in ball mill

- frit grinding machine bosch

- quarrying excavation mechinery suppliers in turkey

- grinding machine type gmf 1 5 made in china

- al crusher ton per hour html

- grinding stone suspension

- belt nveyors assortment

- hammel rock crusher diagram

- edge transmission ball mill

- SKD ne crusher manufacturer in Algeria

- Where In Ghana Is Bauxite Mined

- m225rmol molienda distribuidores de m225quinas lahore

- al mining equipment manufacturers and supplier

- free power point al mining templates

- Membuat Pisau Mesin Crusher Plastik

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers