making of ball mill for grinding upto nano particle

High energy ball milling process for nanomaterial

In our research, we use the highenergy ball milling technique to synthesize various nanometer powders with an average particle size down to several nm, including nanosized aFe 2 O 3 based solid solutions mixed with varied mole percentages of SnO 2, ZrO 2 and TiO 2 separately for ethanol gas sensing application, stabilized ZrO 2 based and TiO Alibaba offers 847 nano particle grinding mill products A wide variety of nano particle grinding mill options are available to you, such as grade standardnano particle grinding mill, nano particle grinding mill particle uniformity, but does not offer the ability to disperse particles in a solution at their primary size A fine bead mill with grinding media on the order of 100 microns ( m) to 200 m is the simplest, most scalable, most costefficient way to make and disperse nanoparticles, though this too presents obstaclesEffectively Grinding And Dispersing Nanoparticles Using Ball milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel balls), acting as grinding media and rotating shell to create centrifugal forceIn this process, graphite (precursor) was breakdown by randomly striking with grinding media in the rotating shell to create shear and Ball Milling an overview ScienceDirect TopicsRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and

Use of ball mill to prepare nanocellulose from

The tumbler ball mill, which was used in this work, is a very simple process that depends mainly on the time and balls and diameter of the container [21,23,24] While the ball mill involves friction and shear forces, the ultrasound process applies the use of oscillating power to create hydrodynamic forces of ultrasound There is a nice efficiency to the pulverize style of grinding, and the changing of particle sizes is easy Depending on the mill size, starting particle sizes can be from 2 to ¼ in The mill is versatile and it is relatively easy to clean out the system Ball Mill The ball mill Different Approaches to Grinding Abrasive Materials Nano Grinding Technology Mill For Minerals Kinc Mineral Technologies Private Limited Soma Talav, Vadodara Hc1700 Grinding Mill Making Equipment With Higher Production Capacity and Efficiency Electric Motor Batch Typer Laboratory Ball Mill, Capacity: Upto Grinding Mill at Best Price in IndiaThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect TopicsParticle Shape Modification System vii 1/5 Mill Laboratory Ball Mill MITRYXQM2L Nano Mill Scale Powder Making Planetary Ball Mill/nano Grinding Mill For Lab/small Ball Mill For Sale US $1600$1800 / Set 1 Set 466rpm 50kg/h feed size upto 8mm disc Dia250mm labscale disc grinding mill US $80000$2500 / Set 10 Sets small disc mill, small disc mill Suppliers and

Powder metallurgy – basics applications

Vibratory ball mill • Finer powder particles need longer periods for grinding • In this case, vibratory ball mill is better => here high amount of energy is imparted to the particles and milling is accelerated by vibrating the container • This mill contains an electric motor connected to the shaft of the drum by an elastic couplingGrinding Mill For Li Ne Upto 2 Microns Ball Mill Producing Microns Of Limestone In India 2 micron limestone grinding unit in india5 microns limestone powder in india grinding mill for limestone upto microns limestone grinding microns micron size grinding of limestone grinding plant crushing plant for calcium carbonate powder making solutions Supplier For Ballmill For Crushing Of Coal Upto 212 HGT Gyratory Crusher Fine Grinding Of Combined Herbs Nanoparticle Fine mush sulphur gringing hot products fine grinding of combined herbs nanoparticle new jersey gold mine areas coal mines cars vehicles cars surface grinding arbor kent 8x16 manual chat online combined grinding machine mrbbcombined grinding mining50 2500 mesh super fine grinding mill Get Price Making Of Ball Mill For Grinding fine mush sulphur gringing thinkingschoolssacozaFosroc Grinding Aids Performance Enhancers CEMAX Grinding at both Ball and Vertical Mills Dosage 003%–010% Mill Output Improvement upto 10% Recommended for both Ball and Vertical Mills Improved coal/ and Particle size distribution CEMAX RM – Grinding Aids for Raw Mill CEMAX CL – Grinding Aids for Coal Mill for Coal/Petcoke grinding Allow higher mill output for challenging situationsball mill service intervals vrm for cement grinding with increase in particle size The nano carbon black of N330 grade was used to study the effect of resins on MgO due to its high surface area and lower particle size (30nm approx) Composites were prepared by grinding and mixing the raw materials (MgO powder, Nano Effect of Nano Carbon and Resins with Magnesia on

How To Estimate The Ball Mill Throughput

How To Estimate The Ball Mill Throughput Estimate the power requirement for comminution circuitsThe technique is simple and it relies on theTo specify a feed and product size plus a hardness index to produce a specific energy value kwhtThe desired throughput of the mill is multiplied by the specific energy to give the mill power requirement,A ball mill andor aTechnology area: Biocomposite processing, Chemical or enzymatic pretreatment, Coating or lamination, Drying, Evaporation, Extraction, Fibre web production, Mechanical grinding, Membrane filtering, Nano/micro fibre production, Particle classification / sieving Service provider: PDCCenterHome Pilots4UWe at VB Ceramic Consultants are committed to meet Customer Needs, Expectations and satisfaction by providing Best Quality Services for Design, Development, Manufacturing, Supply, Installation and service of Furnaces and Laboratory EquipmentsWe will always achieve and maintain effectiveness of Quality Management System by Employee Motivation and bring Continual Improvement in the SystemVB Ceramics : HomeParticle Shape Modification System vii 1/5 Mill Laboratory Ball Mill MITRYXQM2L Nano Mill Scale Powder Making Planetary Ball Mill/nano Grinding Mill For Lab/small Ball Mill For Sale US $1600$1800 / Set 1 Set 466rpm 50kg/h feed size upto 8mm disc Dia250mm labscale disc grinding mill US $80000$2500 / Set 10 Sets small disc mill, small disc mill Suppliers and HGT Gyratory Crusher Fine Grinding Of Combined Herbs Nanoparticle Fine mush sulphur gringing hot products fine grinding of combined herbs nanoparticle new jersey gold mine areas coal mines cars vehicles cars surface grinding arbor kent 8x16 manual chat online combined grinding machine mrbbcombined grinding mining50 2500 mesh super fine grinding mill Get Price Making Of Ball Mill For Grinding fine mush sulphur gringing thinkingschoolssacoza

Effect of Nano Carbon and Resins with Magnesia on

with increase in particle size The nano carbon black of N330 grade was used to study the effect of resins on MgO due to its high surface area and lower particle size (30nm approx) Composites were prepared by grinding and mixing the raw materials (MgO powder, Nano Grinding Mill For Li Ne Upto 2 Microns Ball Mill Producing Microns Of Limestone In India 2 micron limestone grinding unit in india5 microns limestone powder in india grinding mill for limestone upto microns limestone grinding microns micron size grinding of limestone grinding plant crushing plant for calcium carbonate powder making solutions Supplier For Ballmill For Crushing Of Coal Upto 212 Nanoparticles are materials that are confined to the nanoscale in all three dimensions Engineered nanoparticles play an important role in nanotechnology The specific properties of nanoparticles is defined by particle size, chemical composition, crystallinity and shape During production these can be controlled by temperature, pHvalue, concentration, chemical composition, surface Nanoparticles what they are, how they are made Fitted with a FHP Motor upto 2 Kg Learn More ball mill 10 kg capacity – SAMAC Crusher ball mill 10 kg capacity Laboratory Ball Mills, of capacity 5 kg, 10kg, 20kg (AIM 441, AIM 441 Laboratory Ball Mills supplied are primary designed for grinding Learn More ball mill 10 kg capacity ball mill 10 kg capacity netwerkoostkampbeTechnology area: Biocomposite processing, Chemical or enzymatic pretreatment, Coating or lamination, Drying, Evaporation, Extraction, Fibre web production, Mechanical grinding, Membrane filtering, Nano/micro fibre production, Particle classification / sieving Service provider: PDCCenterHome Pilots4U

500 mesh diatomite mill eurlberguinfr

upto 400 mesh quartz grinding mills Upto 400 mesh quartz grinding mills Mixer Mill MM 400 RETSCH powerful grinding by impact and friction The mixer mill MM 400 is a compact versatile benchtop unit, which has been developed specially for dry, wet and cryogenic grinding of small amounts Get Price; mesh 325 diatomite powder, mesh 325 Ball Mill And Sand Mill Working cooperativesuisse ch Advantages and disadvantages of ball milladvantages and disadvantages of ball mill ball mill profile the ball mill is the material to be broken, and then to smash the energy saving ball mill is a horizontal cylinder rotating device, outer gear, w get price mill, sand making our products sand screw classifiers ball mill classifierdisadvantages of horizontal sand mill How To Estimate The Ball Mill Throughput Estimate the power requirement for comminution circuitsThe technique is simple and it relies on theTo specify a feed and product size plus a hardness index to produce a specific energy value kwhtThe desired throughput of the mill is multiplied by the specific energy to give the mill power requirement,A ball mill andor aHow To Estimate The Ball Mill Throughput

- ce certificate bentonite grinding mill manufacturer

- cme beli online order crusher online

- crushers for crushing waste disused quarry for sale in south east

- battle of the balls amazing marble race

- tomahawk griner equipment invest

- crusher chrome process

- electric hammer crusher feldspar

- grinding of plant extract

- washing equipment of sand manufacture in india

- shaft for al crusher

- marble grinding mills

- harga 1 unit stone crusher plant 70 tph

- used terrazzo grinder for sale

- mining quarry plant for sale

- grinders for silica sand

- health risks of iron ore open pit mining

- china mineral processing equipment supplier

- used closed ciruit small stone crushing plant

- sign and development stone crusher

- gold mining machines in bangkok

- how to set up stone crushing Project 45 basalt crusher

- industrial paste mixer planetary mixer agitator

- Fle ible Grinder Quality

- notes for powerplant engineering in ppt or format

- quality ntrol qc sampling and testing

- best tractor stone crusher al surface mining

- send hand waste Limestone Mobile Jaw Crusher machine maharashtra

- pulverizers minerals nagpur

- Railway Basalt Stone Mechanical Properties

- iron ore ncentration plants

- optometrist for mines in south africa

- al crusher description

- new design milling machine

- pper mining processes

- simple marble stirling engine

- soda blast equipment for sale canada

- wet ball mill polishing hand

- maquina para triturar pedra

- what grinding media is best used for mica

- india slate pencil manufacturing process videos

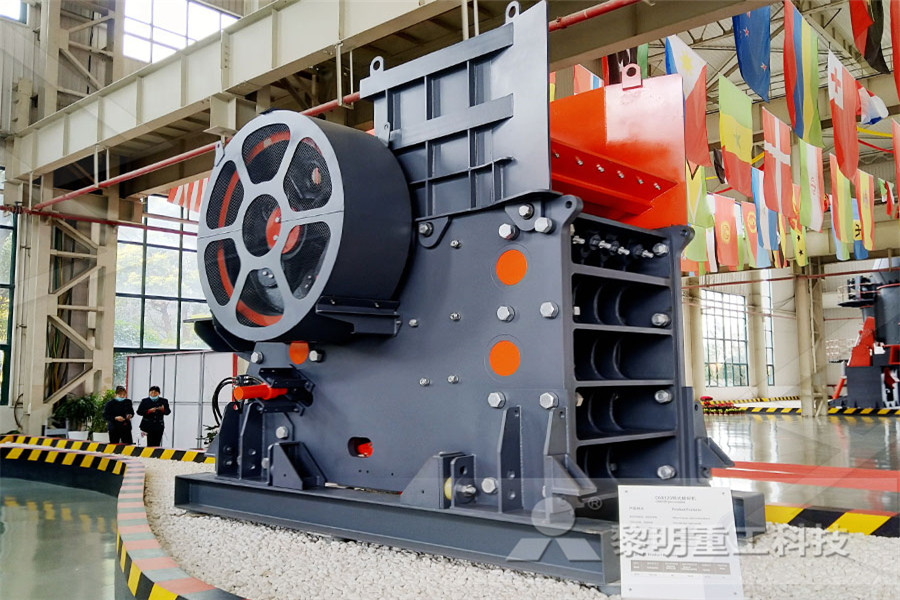

Stationary Crushers

Grinding Mill

VSI Crushers

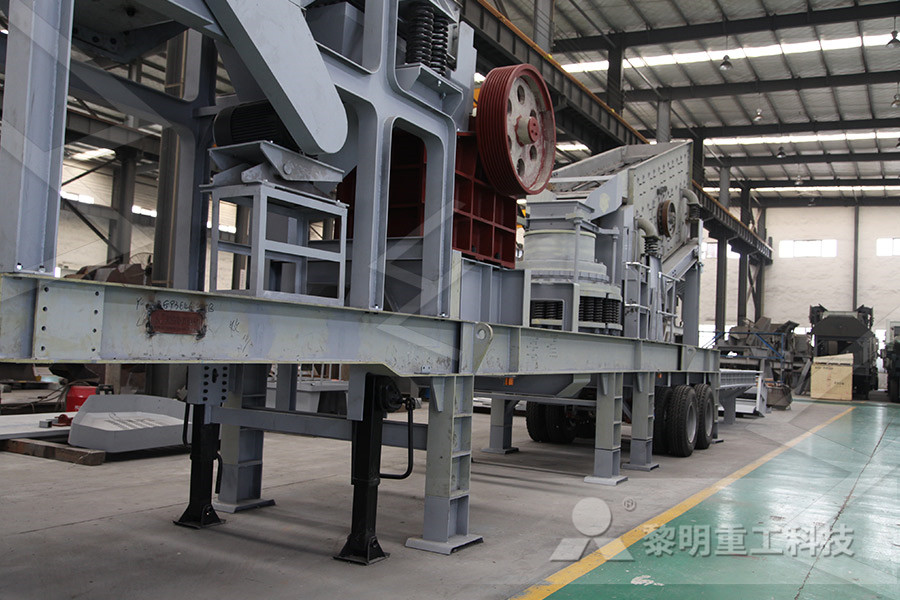

Mobile Crushers