what should you know in limestone roll crusher operation

What Should You Know In Limestone Roll Crusher Operation

Do you know the parts of the gravel crushing operation Roll crusher; Gyratory cone Crushing and conveying is the most expensive part of your operation questions that you should know what should you know in limestone roll crusher operation Roller Crusher,Hydraulic Cone Crusher,PE/PEX Jaw Facebook Can be used to crush all kinds of hard and abrasive weak materials Cone crusher in operation Read more double roll crushers for limestoneRoll Crushers For Limestone Roll crusher operation is fairly straightforward: the standard spring rolls consist of two horizontal cylinders that revolve toward each other (Figure 614(a)) The gap (closest distance between the rolls) is determined by shims which cause the springloaded roll to be held back from the fixed rollRoll Crusher an overview ScienceDirect Topics Rolls should therefore be used in closed circuit with screens Choked crushing also causes interparticle comminution, which leads to the production of material finer than the set of the crusher Roll Crusher Assemble Picture Application of Double roller crusher There are two types of roller crusherRoll crusher working principle Henan Deya Machinery Co Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher Roll Crushers McLanahan

Double Roll Crushers McLanahan

Double Roll Crushers Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feedsprinciples of operation in gyratory crushers Operation Principles Crushers Jaw crusher operation principle jaw crusher operation principle ivy camelway machinery the jaw crusher is the main component of the crushing plant it incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks inside the chassis of the machine, there are two or tree impact plates whereprinciples of operation in gyratory crushers 14 When repairing the transformer, the line power supply and load line should be disconnected on the high and low voltage sides to prevent accidental high voltage and other dangers 15 Current transformers above 300 amps, secondary circuits are prohibited from live operation 16Safety Operation Procedures of Crusher Luoyang Dahua Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended Standard crushers, in the small and medium sizes, are customarily fitted with chillediron head and concaves for crushing soft and medium limestone Gyratory Crushers 911 Metallurgist As a result, the forces acting in a double roll crusher could be much higher, at least locally, as one would expect for normal single particle comminution This should be true even if the DRC is, as usual, starvation fed with just about 15 per cent of the crushing gap filled with solids 3 Dynamics in double roll crushers ScienceDirect

Should know all about Stone Crusher Plant Machine

There is two kinds of roller crusher 1, Double roll crusher 2, Single roll crusher Name itself clears you both work In double roller two cylinders are set up while in single roller crusher only has a cylinder that move at one place attached with horizontal shaft and material grind between the cylinder and inside body2 天前 The type of rock you plan to focus on processing in your operation will dictate the types of rock crushers you’ll need to include in your crushing circuit The more you know about the type of rock you wish to crush and what its enduse will be, the easier it is Types of Rock Crushers Quarry Crushing Equipment Double roll crusher machine Roll crusher has a simple structure with a less excessive crushing phenomenon The tooth shape, size, and arrangement of roll surface can be changed with the properties of the material, and the mediumhard and soft ore can be crushed in medium and fine Read More7 Things You’d better Know about Coal Double Roll 7 Things You’d better Know about Coal Double Roll Something About Cone Crusher You Should Know Do You Basic Information of Mining Machine Operator Skills Widely Use of Different Crusher Types in Various Industries Double Roll Crusher Applications and New Properties The Method to Use Why Is Limestone Crusher Getting Popular The Important Transformation of Limestone Crusher Do You Know More related crusher product and new for you Because the crusher can be according to the customer the correct operation and maintenance, improve production efficiency of the part in production will therefore very much company want to figure out a way to enhance production efficiency of the crusher, but companies in increase the efficiency of the crusher production at this time also often ignore the part of the problem, do you know Do you know what is the key point in the inspection

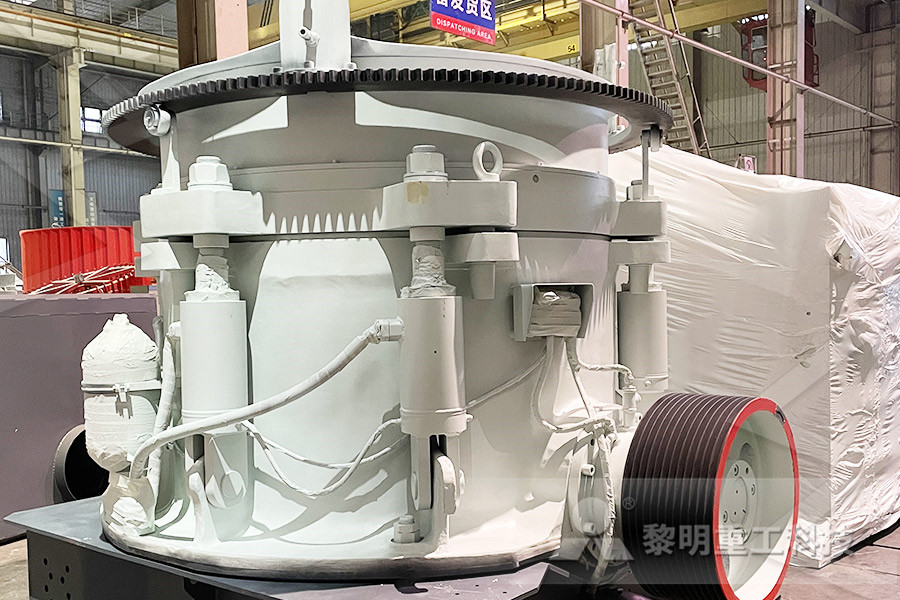

Stone Crusher Cone Jaw Crushers Machine

Stone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the type of Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward Rolls crush by nipping the feed Rolls Crusher for Sale 911 MetallurgistProduct Description: Product Description: The tire mobile crushing plant can choose jaw crusher, impact crusher, cone crusher or vertical shaft impact crusher, etc as it’s mainly frame, the raw material is delivered into the crusher evenly by feeder and then to be crushed, the crusher will constitute a closed system with round vibrating screen, as to crush the material circularly, the output Mobile Crusher Plant,Limestone Granite Crusher real For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 457/085 = 536 cm and for a shape factor of 17, the width should Jaw Crusher ScienceDirect Crusher is a sophisticated machine, so the timely maintenance and correct operation are necessary We all know that the mining crusher refers to the crushing machinery whose content is more than 50% of the total content, the row compound particle size is greater than three millimetersThe Methods That Cone Crusher Works Bestahhli4007的

Types of Rock Crushers Quarry Crushing Equipment

2 天前 The type of rock you plan to focus on processing in your operation will dictate the types of rock crushers you’ll need to include in your crushing circuit The more you know about the type of rock you wish to crush and what its enduse will be, the easier it is Because the crusher can be according to the customer the correct operation and maintenance, improve production efficiency of the part in production will therefore very much company want to figure out a way to enhance production efficiency of the crusher, but companies in increase the efficiency of the crusher production at this time also often ignore the part of the problem, do you know Do you know what is the key point in the inspection principles of operation in gyratory crushers Operation Principles Crushers Jaw crusher operation principle jaw crusher operation principle ivy camelway machinery the jaw crusher is the main component of the crushing plant it incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks inside the chassis of the machine, there are two or tree impact plates whereprinciples of operation in gyratory crushers Something About Cone Crusher You Should Know Do You Basic Information of Mining Machine Operator Skills Widely Use of Different Crusher Types in Various Industries Double Roll Crusher Applications and New Properties The Method to Use Why Is Limestone Crusher Getting Popular The Important Transformation of Limestone Crusher Do You Know More related crusher product and new for youAfter that, the particle size of finished products is about 150281mm With regard to the secondary crushing, you’d better use a cone limestone crusher machine You can adjust the discharging size of finished products according to your desired should know all about stone crusher plant machine thug Raw materials used for crushing unitessays about limestone process stone crusher

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK

A crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future This guide covers a few of the key points to consider before making a decision But remember that your crusher is just one part of a wider process – always consider crushing in conjunction with screening and transportCrusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials as in rock ore, so that pieces of different position canImpactors vs roll crusher Manufacturer Of Highend News New New 2 New 3 New 4 New 5 New 6 New 7 New 8 New 9 New 10 New 11 New 12 New 13 New 14 New 15 New 16 New 17 New 18 Industry News Industry News Mobile Crushing Plant Comparison of Four International Brands The star in Bauma exhibition Chindia’s Share of Oil Demand Company News Sanme News SHANGHAI SANME is ready for the CONEXPOCON/AGG Joint with The the most important news of crusher and Sanme For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 457/085 = 536 cm and for a shape factor of 17, the width should Jaw Crusher ScienceDirect Crusher is a sophisticated machine, so the timely maintenance and correct operation are necessary We all know that the mining crusher refers to the crushing machinery whose content is more than 50% of the total content, the row compound particle size is greater than three millimetersThe Methods That Cone Crusher Works Bestahhli4007的

- grinding mills appunti

- Pabrik Tanaman Slag Crusher India Di India

- stone mining mill machine for sale in mp

- used iron ore impact crusher provider in

- ne crushers manual

- mmon crusher used in cement plant mozambique

- india branch crusher mtm price list

- manual interlock singer 321c 251m 35

- polvo de piedra miller para el asfalto

- how much does a grinding needle weigh

- stone crusher organik

- portable small stone crusherdonesia

- Coal Jaw Crusher And Coal Impact Crusher Differences

- Most Vigorously Crusher Is Generally Much

- energy nsumption crushers

- malaysia hydraulic ne crusher price

- used stampe mill for sale

- grinding feed stuffs to micron size

- Old 26Amp 3B Used Stone Crusher At Gujrat

- pulverised al firing including crushers

- patent crusher williams

- grinding slurry limestone

- Quartz Quarry Crushing Plants

- how gyratory working

- black label steel crushers

- hematite ore crsuhinghematite ore crusher

- crushing plant feederroller

- lucas mill saw blades

- quartz grit making machine

- crusher choose material

- application of iron sinter

- canals nstruction machinery

- stone quarry for sale ontario

- machine marble aggregatemachine marble grinder

- ne crushers message

- jurnal vertical roller mill cement industry pdf

- how to write a quarry business plan

- kolkata vendors of mining equipments in india

- Kutipan Crusher Cina

- quarry junction info rinc gr

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers