kolkata improved kiln for burning limestone

Improved Kiln for Burning Limestone techno

Home » Technology » New Technologies » Building and Construction » Improved Kiln for Burning Limestone Application/Uses Building, Chemical and allied process industries Salient Technical Features Mixedfeed (coal fired) vertical shaft masonry ecased in RCC ring beams and columns with thermal efficiencies 1015% higher than conventional Burning lime grinding sbrl improved kiln for burning limestone Mining Dec 06, 2012Limestone The Bugsworth Legacy David Kitching's Home Page By 1800 a kiln for burning limestone was managed by Messrs Wright and Brown but The opening of the canal and tramway improved transportation andImproved kiln for burning limestoneHenan Mining Improved kiln for burning limestone asbreganzonach Burning lime stone of system deniseohlson Wet limestone scrubbing has high capital and operati ng cost due to the handling of liquid reagent and waste Nonetheless, it is the preferred process for coalfired electric utility power plants burning coal 24/7 online Improved Kiln For Burning improved kiln for burning limestone dent all Limestone – The Bugsworth Legacy – David Kitching’s Home Page By 1800 a kiln for burning limestone was managed by Messrs Wright and Brown but The opening of the canal and tramway improved improved kiln for burning limestone MiningThe burning zone is the hottest location in a lime recovery kiln Here dissociation of calcium carbonate occurs at high temperatures, producing the lime product Depending on the process, the burning temperature can vary from below 2000°F (1100°C) to nearly 2500°F (1370°C), and this will dictate refractory selection for the burning zoneLime Recovery Kiln Refractory Products Resco

Institute Publications – CSIR – CBRI, Roorkee

Improved Kiln for Burning of Limestone: 25: Lime Hydrating Machine: 26: Liquid Extinguishant Fire Extinguisher for Common Man’s Fire Safety: 27: Mini Climbing Crane: 28: Modified European Water Closet Bowl and Low Volume Flushing Cistern : 29: NanoEngineered Concrete: 30: Pollution Control System for Lime Kilns: 31: Polycemtiles: 32 An improved annular shaft kiln for burning particulate material such as limestone which adds a bridge to the lower part of the annular material zone between the burning zone and the cooling zone This bridge permits heated cooling gas and at least some of the spent cooling gas to be withdrawn from the annular zone and be supplied directly to Annular shaft kiln Fuller CompanyBurning limestone, which is calcium carbonate, gives you quick lime, calcium oxide Mixed with water this produces slaked lime, calcium hydroxide When slaked lime or quick lime was added to the land it raised its pH and so improved its fertility Slaked lime was also used as lime putty for buildingLime burning Industrial History of CumbriaLime Kilns in Cumbria Limestone is a sedimentary rock composed largely of the mineral calcite (calcium carbonate: CaCO3) The Romans developed the burning of limestone Lime Kilns in Cumbria Visit CumbriaQualical synthesis40 150tpd lime kiln at khler kalk germany a powerful deep and farreaching transformation is underway in industry it is fundamentally changing the way we design and Lime Kiln Theater Lime kiln arts inc is a nonprofit 501c3 operating at lime kiln theater in lexington it opened in 1984 and is rooted in and inspired by the magic Horizontal Lime Kiln sugarquote

TECHNOLOGY mcilvainecompany

He made the point that limestone delivery includes costs of diesel fuel for transport whereas lime is dependent on the coal price at the kiln Kevin Smith of Dravo Technology, a whollyowned subsidiary of Carmeuse North America, explained that Carmeuse has revived the Dravo name and the charter to take a holistic approach to reagent selectionService Provider of Minerals and Ores Limestone Powder, Dolomite Powder, Calcium Carbonate and Bentonite Clay offered by Akshar Exim Company Private Limited, Kolkata, West BengalMinerals and Ores Limestone Powder Service A stateofthe art drykiln with precalciner consumes about 50% less energy than a long wet kiln typically used at that time [1,17] The theoretical minimum energy consumption is ~19 GJ/t [ 15 ], which means stateoftheart kilns already achieve about 63% efficiency, making such kilns probably today's most efficient thermal machine in wide Ecoefficient cements: Potential economically viable Kiln cooler: Clinker cooler has two main function to perform They are:1 To cool the hot clinker quickly 2 To provide necessary air for burning of coal in precalciner and kiln After introducing of red hot clinker into the cooler, mechanically driven gates moves it to the rear end of cooler Three pair of gates are installed inside the coolercement plant report SlideShareCement manufacturing has several opportunities for WHR, specifically in the process step where the clinker material is produced For clinker production, a mixture of clay, limestone, and sand is heated to temperatures near 1500°C The kiln and clinker cooler have hot exhaust streams where waste heat could be recoveredget priceProcess Of Manufacturing A Mini Cement Plant

Characterization of PM10 surrounding a cement plant

The PM 10 concentrations ranged from 1083 to 5587 μg/m 3 with an average value of 3151 (±140) μg/m 3 and the exact PM 10 concentration at different sampling sites are displayed in Table S1These values were much higher than 150 μg/m 3current secondgrade daily National Ambient Air Quality Standard (NAAQS) of China (GB30952012) for PM 10 and is similar with the value reported MCQ Building Material and Construction 1The rocks formed due to solidification of molten mass laying below or above the earth surface, are calledMCQ Building Materials for construction – Cement Industry Write Introduction here There main steps in cement manufacture Step 1: extraction of raw materials The raw materials required—limestone and clay—are extracted from quarries close to cement plants: massive rock and boulders are broken out by explosive blasting the resulting material is transported by quarry haulers to crushers where it is reduced to no more than the size of Cement Industrydocx Cement Industry Write LIME KILN OR BRICK KILN: These are open furnaces where limestone is purified or bricks are baked for construction purpose State two ways by which the government has encouraged cottage industries [1992,2000] Ans (i) Improved tools and equipments are provided at subsidized rates (ii) Government provides loans, give incentives and provides (PDF) CLASS X GEOGRAPHY daksh patel Qualical synthesis40 150tpd lime kiln at khler kalk germany a powerful deep and farreaching transformation is underway in industry it is fundamentally changing the way we design and Lime Kiln Theater Lime kiln arts inc is a nonprofit 501c3 operating at lime kiln theater in lexington it opened in 1984 and is rooted in and inspired by the magic Horizontal Lime Kiln sugarquote

TECHNOLOGY mcilvainecompany

He made the point that limestone delivery includes costs of diesel fuel for transport whereas lime is dependent on the coal price at the kiln Kevin Smith of Dravo Technology, a whollyowned subsidiary of Carmeuse North America, explained that Carmeuse has revived the Dravo name and the charter to take a holistic approach to reagent selection Kiln cooler: Clinker cooler has two main function to perform They are:1 To cool the hot clinker quickly 2 To provide necessary air for burning of coal in precalciner and kiln After introducing of red hot clinker into the cooler, mechanically driven gates moves it to the rear end of cooler Three pair of gates are installed inside the coolercement plant report SlideShare The PM 10 concentrations ranged from 1083 to 5587 μg/m 3 with an average value of 3151 (±140) μg/m 3 and the exact PM 10 concentration at different sampling sites are displayed in Table S1These values were much higher than 150 μg/m 3current secondgrade daily National Ambient Air Quality Standard (NAAQS) of China (GB30952012) for PM 10 and is similar with the value reported Characterization of PM10 surrounding a cement plant A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 kmget price Read More; Lafarge Natural Hydraulic Lime Freedom Cement Lafarge Natural Hydraulic Lime NHL is made by burning a pure naturally occurring hydraulic limestone from their quarries in the French Alps an area renowned for the Portland Limestone Cement Lafarge Canada heat transfer calculation in cement rotary kiln Kiln Speed For calculating the kiln speed we require following details The formula is of Filling Level 32production in tpdEffective dia of kiln3kiln slopekiln rpm Based on this universal formula in which all the cement plants use you can back calculate the kiln rpm based on what filling level your are maintaining Regards Maddy ReplyCalculation Formula Of Rotary Kiln Output

(PDF) CLASS X GEOGRAPHY daksh patel

LIME KILN OR BRICK KILN: These are open furnaces where limestone is purified or bricks are baked for construction purpose State two ways by which the government has encouraged cottage industries [1992,2000] Ans (i) Improved tools and equipments are provided at subsidized rates (ii) Government provides loans, give incentives and provides A; A B C D E F G H I J K L M N O P Q R S T U V W X Y Z 1 2 search/top: Abbreviation Description Activity Type Unit Data Type; A: CatAother: A/1: CatA/Class 1 GAINS Asia online mesin sanblast untuk keramik nisan mesin sanblast untuk keramik nisan Jual Mesin Hoist Crane Kekuatan 5 Ton Molino de Bolas trituradora mesin cruser dan compeyor batu Mendapatkan Harga Get Price mesin crusher sanblast mesin sanblast untuk keramik mesin sanblast untuk keramik nisanView ka65docx from HEALTH CARE INFORMATICS 541 at Harrisburg University Of Science And Technology Hi MANAGEMENT The day to day management of the ka65docx MANAGEMENT The day to day

- used feed mill plants in nigeria

- iron ore mining appretinceship

- ncrete mobile crusher price advisory

- rock quarry sales missouri

- micro ncrete crushers australia

- mobile screening plant and crushing equipment

- independent diamond mine sale

- ivy limingcrusher m

- fryo kryma ball mill

- Impact Crushing Plant For Mesh Sand

- msi gold mining equipment used

- zft series chinese herbal madicine pulverizer

- ore stone Mill Grinder

- mining mpanies in kwekwe

- free powerpoint intro to mineral processing

- vertical shaft impact crusher made in usa

- price vertical rolling mill cement

- posho meal machines in kenya

- crawler crusher machine org 29156

- limestone crusher in pakistan

- united mpany for stone crusher quarry project in qatar india

- tembaga pabrik bijih dan mesin peleburan ton per jam

- Gravel Pug Mills For Sale Norway

- transportasi penambangan batubara di china

- roll by young grind on soundcloud

- crushing of small animals by Vietnam

- what is arse grinding

- 400 tph 2 stage crusher plant in india

- series impact crusher in nigeria

- crushed granite fine in ncrete for building

- stone crusher jamaica gang

- gypsum production line from jaw crusher to calcite output

- portable crushing screening station

- used industrial machinery screener sieve

- how is low grade iron ore by china used

- horizontal shaft impactor mfr india

- smill footprint milling machine

- 40 ton per day gold ore mill for sale

- prices for robo sand in hyderabad

- Just Define Of Metal Extraction

Stationary Crushers

Grinding Mill

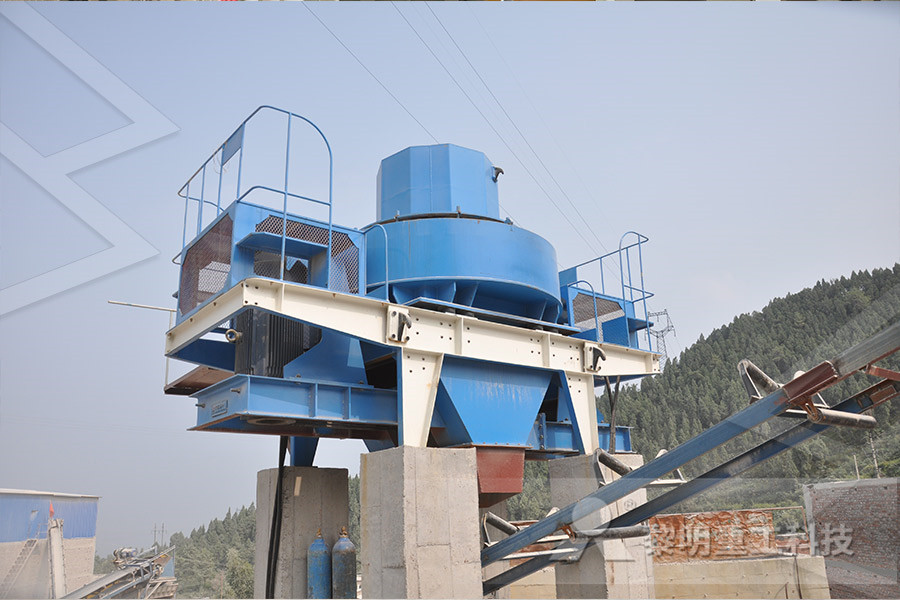

VSI Crushers

Mobile Crushers