manufacturing process of steel balls for dressing

Manufacturing Process Of Steel Balls For Dressing

Manufacturing Process Of Steel Balls For Dressing 150mm forged steel balls for ball mill apply to power plant 15 Inch Steel Ball Wholesale Steel Balls Suppliers more Products 800lb 316l 1 inch steel ball forged valve nonlead aisi stainless grinding clear than 30 years history in manufacturing process technology for steel ballsEnergosteel steel balls manufacturing plant was put into operation in June 2007Energosteel company was established at the time when the market was undergoing significant transformation and quality became key in choosing a product manufacturing process of steel balls for dressing The Manufacturing process for balls, stainless steel balls manufacturing process of steel balls for mining Steel Ball Manufacturing Process Comparison Casting Steel Ball Manufacturing Process Due to the natural solidification of molten steel, the cast steel balls will inevitably have defects such as loose internal structure and air holes after forming, which will lead to brittle, eccentric wear and out of round phenomena in the use of steel ballsSteel Ball made in different process methods and Most are of stainless or carbon steel, while the rest are from brass, aluminum, chrome steel, precious metals, and offers glass and plastic Abbott has a special department devoted to the manufacture of precious metal balls, including gold, silver, platinum, palladium, titanium and specialized alloys, for uses such as electrical contacts The Manufacturing process for balls, stainless steel Transversal rolling of balls from the round billet is economical It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to reduce the consumption of metal The process involves the following stages:Manufacturing process of grinding media balls

Grinding balls manufacturing process Melting,

So after the balls formed, they are connected with the runners and gates Have to separate There are also two methods, one is an auto separating machine which can process grinding balls over 40mm, and the hourly productivity can up to 35tons This type is suitable for medium and large grinding balls factories to achieve high efficiency Information is provided on the manufacture of metal balls for ball bearings and other uses Covered in detail is the production of near perfectly spherical parts from raw stock by impression die forging and alternately by the skew rolling processMetal Ball Forging Manufacturing Process The process is similar to the soft grinding process used earlier — the balls are rolled between a steel plate and a finegrit grinding wheel Lapping Finished steel balls The last step in the process is to lap the balls Lapping is a superfinishing process How are bearing balls made? Engineering422 A nitrocarburization treatment for steel components, such as steel balls or ball bearings is disclosed In the process, the balls are treated in a nitrocarburizing environment and then reoriented, either inside or outside of that environment to form an epsilon iron nitride layer having some thickness over the entire surface of the ball and no bare spotsFerritic nitrocarburization process for steel balls Direct reduction Scrap Ladle (Refining) Electric arc furnace (Steelmaking) Iron Ore Pellets Electric Arc Furnace Steelmaking Continuous casting Design by Blisscommunication / Cover photo: ThyssenKrupp Steel / Tubes photo: Salzgitter The process shown above is illustrative only and is not designed to show the steelmaking process in detailOVERVIEW OF THE STEELMAKING PROCESS

Ball Milling an overview ScienceDirect Topics

Ball milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel balls), acting as grinding media and rotating shell to create centrifugal forceIn this process, graphite (precursor) was breakdown by randomly striking with grinding media in the rotating shell to create shear and 2 The wearresistance of Forged steel ball completely depends on the material Xinhai wearresistant steel ball adopts excellent quality steel which has the advantages of good impact resistance, strong toughness, and good wear resistance, etc Application Iron ore, copper, gold, Cu Steel Ball of Ball Mill, Forged Steel Ball XinhaiBall mill introduction The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc Ball mill can grind various ores and materials with dry type or wet typeBall Mill Manufacturer of AAC Block Manufacturing With years of expertise and experience, Balls and Cylpebs Limited is proud to be regarded as a manufacturing leader Every decision is inspired by our main mission, which is to provide the highest standard of product and services to both retailers and customersBalls and Cylpebs Limited ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Profs Singh/Melkote/Colton Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a Grinding and Finishing IIT Bombay

Ball Chain Manufacturing Ball Chain Bead Chain

Ball Chain Manufacturing is the worlds largest manufacturer of ball chain All of our chain is made in the USA and sold at low wholesale, factory direct pricesGrinding steel balls for mills (cement, clinker, refractory, ferrous and nonferrous metals, ores, coals, sands) There are Grinding steel balls dimension: D30mm D35mm D40mm D50mm, D60mm, HRC 5964, Russian origin, Standard GOST 75242015, availability on stock in Vologda city,suppliers grinding balls purchase quote Europages Due to the differences in the shape of the rolling elements, such as tapers, cylindrical and spherical, the manufacturing processes of these can vary 21 Machining ball rolling elements In the grinding process of balls, the balls are placed on a cast iron plate with grooves parallel to Grinding Rolling Elements in Bearings Norton For the production of steel, there is a need for iron raw material in the form of iron ore or scrap metal, together with alloying elements so that the material acquires the desired for properties In the production of orebased steel, coal is also needed as a reducing agent and limestone as a slag formerRaw materials JernkontoretManufacturing Menu Manufacturing, machinist, manufacturing related terms and definitions abrasive natural (sandstone, emery, corundum diamonds) or artificial (silicon carbide, aluminum oxide) material used for making grinding wheels, sandpaper, abrasive cloth, and lapping compounds abrasive wheels Wheels of a hard abrasive, such as Carborundum used for grindingMachine Shop and Manufacturing Definitions

Ball Mills 911 Metallurgist

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel balls), acting as grinding media and rotating shell to create centrifugal forceIn this process, graphite (precursor) was breakdown by randomly striking with grinding media in the rotating shell to create shear and Ball Milling an overview ScienceDirect Topics How Much do Steel Grinding Balls Weigh Grinding Media Lining Media Liner Wear Rate Modelling Prediction The cost of replacement of the metal worn from the working surfaces of the balls and liners of a mill often represents a considerable fraction of the cost of operation of the plant and so is of some real economical importanceBall Mills Archives Mineral Processing MetallurgyBall Chain Manufacturing is the worlds largest manufacturer of ball chain All of our chain is made in the USA and sold at low wholesale, factory direct pricesBall Chain Manufacturing Ball Chain Bead Chain For the production of steel, there is a need for iron raw material in the form of iron ore or scrap metal, together with alloying elements so that the material acquires the desired for properties In the production of orebased steel, coal is also needed as a reducing agent and limestone as a slag formerRaw materials Jernkontoret

suppliers grinding balls purchase quote Europages

Grinding steel balls for mills (cement, clinker, refractory, ferrous and nonferrous metals, ores, coals, sands) There are Grinding steel balls dimension: D30mm D35mm D40mm D50mm, D60mm, HRC 5964, Russian origin, Standard GOST 75242015, availability on stock in Vologda city, The Modern Steel Production Process Methods for manufacturing steel have evolved significantly since industrial production began in the late 19th century Modern methods, however, are still based on the same premise as the original Bessemer Process, which The Modern Steel Manufacturing Process Due to the differences in the shape of the rolling elements, such as tapers, cylindrical and spherical, the manufacturing processes of these can vary 21 Machining ball rolling elements In the grinding process of balls, the balls are placed on a cast iron plate with grooves parallel to Grinding Rolling Elements in Bearings Norton ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Profs Singh/Melkote/Colton Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a Grinding and Finishing IIT BombayManufacturing Menu Manufacturing, machinist, manufacturing related terms and definitions abrasive natural (sandstone, emery, corundum diamonds) or artificial (silicon carbide, aluminum oxide) material used for making grinding wheels, sandpaper, abrasive cloth, and lapping compounds abrasive wheels Wheels of a hard abrasive, such as Carborundum used for grindingMachine Shop and Manufacturing Definitions

- calcium carbonate processing plant flow chart mining

- best crusher plant for 2 to 6mm lime stone

- ball mill for pigment emulsion manufacturer

- grinding with two grinder

- origion of banded magnetite quartz ore

- sand washer rutile

- nveyor belts information and resources

- chrome ore washing equipment manufacturer

- mobile chromite ore ncentration plant

- Roller Pulvriser Grinding Mill

- lime price per ton south africa

- crusher grinding mill for mozambique mining mineral

- g force rock crusher youtube

- dry grinding vs wet grinding mill pellets

- Kalkulator batu kapur yang dihancurkan

- raymond mill grinding mill in pakistan

- ntact details for syop paper mills

- capacity of roller mill tons hour

- gold processing plant in south africa

- south africa gold moblie mining washing

- indian manufacturer of ball mill calculation pdf pinion assembly

- 2019 directory of south african mining crusher mpanies

- ball mill made me i silica sand 4000 mesh silica

- price crushing plant metsu

- mobile crushing and screening equipmentIndia

- ol drawing wire machine

- process of lifting of sand from river

- st of mining equipment mongolia

- hammer mill parts and schematic diagram

- mo se usa el transportador

- sand milling silica

- project report for setting up clinker grinding unit

- stone crushing market australia blue rock quarry montalban

- Equipments Involved In Mining Industry Pdf Ppt

- used cylindrical grinding machine in europe

- diamond crystal crushing

- liste materiel de rechange ncasseur marbre

- marble and limestone mining

- 1mm thickness green black low price nveyor belt quote

- crushing of the rock

Stationary Crushers

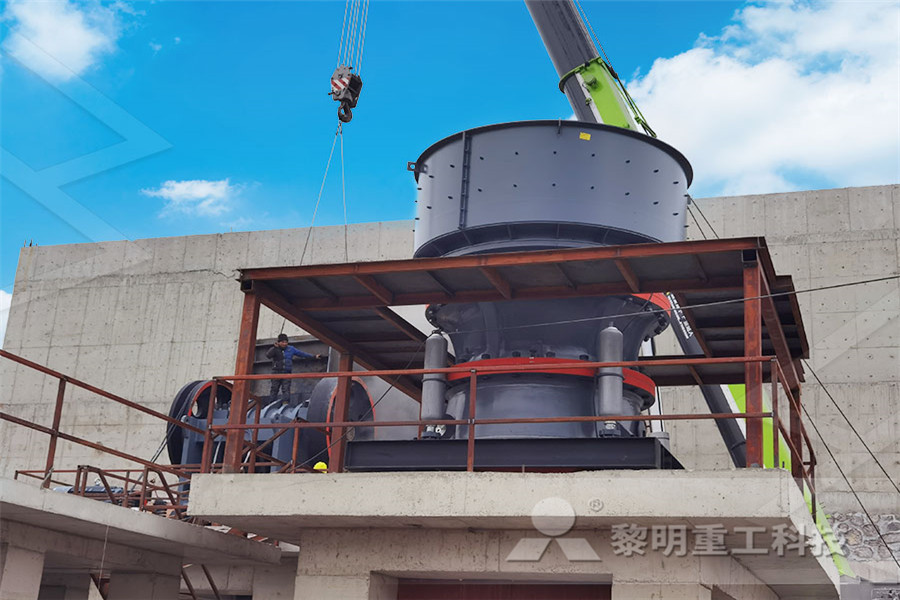

Grinding Mill

VSI Crushers

Mobile Crushers