pulverizer mill lube system

Luminant

PULVERIZER MILL LUBE OIL PRESSURE LOW The Luminant Power Optimization Center identifies, forecasts and advises plant personnel of emergent issues impacting production through the integration of remote monitoring, modeling and diagnostics In the current market environment of low natural gas and wholesale power prices, andcoal mill pulveriser lube oil The pulveriser grinds the coal to dust in rotating grinding rollers and sieves, so that it can be used as fuel The pulveriser lube oil is subjected to extreme levels of very fine particles, and many power plants believe the plant should be shut down periodically to change the oilEnsure clean dry lube oil on coal mill pulveriser A pulverizer auxiliary lubrication system (12) particularly suited for use with a pulverizer bowl mill (10) of the type that is operative for effecting the grinding of material The subject auxiliary lubrication system (12) is designed to be employed to supplement the pulverizer bowl mill's (10) existing lubrication system (48) whereby the Pulverizer auxiliary lubrication system Combustion A pulverizer auxiliary lubrication system (12) particularly suited for use with a pulverizer bowl mill (10) of the type that is operative for effecting the grinding of materialUSA Pulverizer auxiliary lubrication system lubrication system ball mill – Ball Mill Lube System, Ball Mills, one of the different types of ball mills used Grinding mill lubrication systems reliability audit and reviewLube System Types For Grinding Mills Crusher Mills, Cone

Lube Oil Systems Temperature Controlled Bypass Valves

Lube Oil Systems Lubrication oil systems are used in many industrial, mobile, and aerospace applications to reduce system wear and increase performance of pumps and engines Proper temperature control of these systems is very important Lube For Lube System Room: Proper Drainage System by having permanent submersible pump Enclose the Lube System room to prevent external contaminant to enter the system 32 Thoughts about the Study: Hydraulic Lubrication system is very important in the MillMill Lubrication System SlideSharePulverizer Mill Lube Oil Pressure Low Power Optimization Center operators are always on alert Complacency is not accepted Read more about how the Power Optimization Center saved a generation facility $688,435 in Total Cost Avoidance by downloading our White Paper now The Luminant Power Optimization Center identifies, forecasts and advises plant personnel of emergent issues impacting Success Stories Luminant In laboratory scale, the particular mill tested in this investigation utilized a sweeping gas system with internal size classification similar to commercialscale units The majority of testing in the MB1 pulverizer was directed to study the drying process Laboratory Sample Pulverizers 911 MetallurgistA pulverizer auxiliary lubrication system (12) particularly suited for use with a pulverizer bowl mill (10) of the type that is operative for effecting the grinding of material The subject auxiliary lubrication system (12) is designed to be employed to supplement the pulverizer bowl mill's (10) existing lubrication system (48) whereby the beneficial features of the latter are retained while USA Pulverizer auxiliary lubrication system

Ball mill/SAG mill drive lubrication system IEEE

Abstract: This paper describes the function and operation of lubrication systems for Ball Mill and SAG Mill Drives Provided within this paper are hydraulic schematics, functional description and a general overview of system layout as well as some of the important features and factors relevant to improving the reliability of this very critical part of the grinding mill drive system In laboratory scale, the particular mill tested in this investigation utilized a sweeping gas system with internal size classification similar to commercialscale units The majority of testing in the MB1 pulverizer was directed to study the drying process and develop techniques to increase the degree of drying, if possibleLaboratory Sample Pulverizers 911 Metallurgist Raymond Mill type Pulverizer – Coal processing system The image below is a schematic flow diagram of a typical oil of Allen Bradley Control Logix bradley pulveriser oil circulation system Mining Pulverizer Maintenance and Repair Inc specializes in coal pulverizer services Our supervisors have more than 30 combined years of experience rebuilding BW MPS and EL mills, CE Mills and Foster Wheeler MB millsPulverizer Maintenance Repair, IncPulverizer Mill Lube Oil Pressure Low Power Optimization Center operators are always on alert Complacency is not accepted Read more about how the Power Optimization Center saved a generation facility $688,435 in Total Cost Avoidance by downloading our White Paper now The Luminant Power Optimization Center identifies, forecasts and advises plant personnel of emergent issues impacting Success Stories Luminant

lube pump to crusher erzherzogalbrechtde

Stone Crusher Pulverizer Coal Mill Reducer Ball mill lube oil system in Home Milling Grinding ball mill drive motor 10hp winsmith gear reducerball mill drive with motor Chat Now the role of the reducer mill lube roller mill role of lube oil pump in coal mills Stone The Causes Of Ball Mill Reducer first start the Suralaya Power Plant unit 14 using coal as fuel, before a coal burned in the living room fuel first crushed using pulverizer (mill)part of Mill has a function to alter the current round of torque electric motor is gearbox, in gearbox pulverizer there are gear accessible teeth and safeguards that require lubrication circulation to minimize wears a socalled system lube oil pulverizerWhen Modifikasi Penambahan Lube Oil Pump Pada In the first computational example the coal pulverizer drive system is considered This machine is driven by the 22 kW asynchronous motor by means of the reduction planetary gear of the resultant ratio 1:533The static characteristic of this motor as well as the drive system first torsional eigenform of frequency 42 Hz are shown in Figs 2a and 2b, respectivelyCoal Pulverizers an overview ScienceDirect Topics (By the way, each of this mill’s five coalpulverizer gearboxes had previously required an annual rebuild) Clearly, there are major cost savings from keeping gear oil clean through proper proactive measures and the right filtration system— savings that can go straight to your bottom lineOffline Filtration: Key To Establishing And Maintaining Raymond Mill type Pulverizer – Coal processing system The image below is a schematic flow diagram of a typical oil of Allen Bradley Control Logix bradley pulveriser oil circulation system Mining

reducer lube roller mill Hillgrove Secondary School

vertical roller mill lubrication system SHAAN LUBE Slab Caster Rolling Mill Lubrication Systems Vertical Roller Mill Reducer (MLX) Zhejiang Dongfang Chat Online; sag mill trunnion lube ring gear lube hotelsheetalnaggar sag mill trunnion lube ring gear lube ( To get products catalog FOB prices MOQ delivery time and payment terms Pulverizer auxiliary lubrication system 20121988 Rather, for purposes of obtaining an understanding of a bowl mill 10 with which an auxiliary lubrication system, generally designated by the reference numeral 12 in FIG 2 of the drawing, constructed in accordance with the present invention is capable of being employed and when so employed therewith is operative as an auxiliary Lubrication Raraymond Mill Bowl MillImproving Coal Pulverizer Performance and Pall Corporation Combustion Engineering 783RP BowlMill Coal Pulverizer BallRace Mills comprise the majority of coal contamination in the lube system can result Read moreLubrication System Of A Coal Ball MillCoal Pulverizer Coal Mill Project Gearbox Filtration Upgrade COT Turbine Oil Coalesce Skid Successful Application Diesel Fuel Filtration Upgrades FSAPE Peaking Power Plant Case Study Soluble Varnish Removal System Extends Fluid Life SVR Lube Oil Varnish Removal Success SVR Reduces MPC by 90% in 45 Days SVR Restores Heavily Varnished Gas TurbineCase Studies PSR Proactive Strategic Reliability Sdn Within a rotatingtype classifier, fine particles are passed through while coarse particles are eliminated by utilizing the relative balance of centrifugal force and centripetal force produced by a blade rotating at several dozen rpm and the flow of air MHI group offers a full lineup of pulverizer / mill systems from small to high capacityCoal Pulverizer Heavy Industries, Ltd

PS410 E and EL Pulverizer Modifications for Optimum

through the mill The existing pulverizer drive motor and fan can be retained after the retrofit is made, however, the full EL unit mounting system and is easier to install Twofluted EL pulverizer cooled heat exchanger to reduce lube oil temperatures This system utilizes the existing oil pump Main shaft air seal housingball mill lubri ion systems Ball Mill Trunnion Bearing Lube System On a 11'6" x 22'0" Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and dischargelubrication system ball mill pumpsball mill trunnion bearing oil seal ring YouTube Dec 24, 2013 The trunnion bearing lube system provides both lift and lubrication for the trunnion bearingsball mill trunnion seals lubrication Ball mill specialists check every process and mechanical aspect of the ball mill system, including: Bearing lubrication system Trunnion Trunnion Oil Circulating Jacking Systems Prolube Marketing, supplying Oil circulating and jacking systems are not only used to pump oil to bearings or ball mill lubrication systems mineequipments

- st of gold digging mills

- all information about granding machine

- cina pemasok crusher berat

- protable ncrete crushing equipment

- is belt nveyor pdf free

- binny ltd cement machinery div

- maize posho mill prices in kenya

- primary jaw crusher used sale in venezuela

- capacity of a vibrating screen

- chicago electric grinder

- flow chart of stone crushing vibration sieve machine silca sand

- beton daur ulang mesin crusher for sale

- free stone crushing machine Project plan ethiopia

- quarry crusher for grante

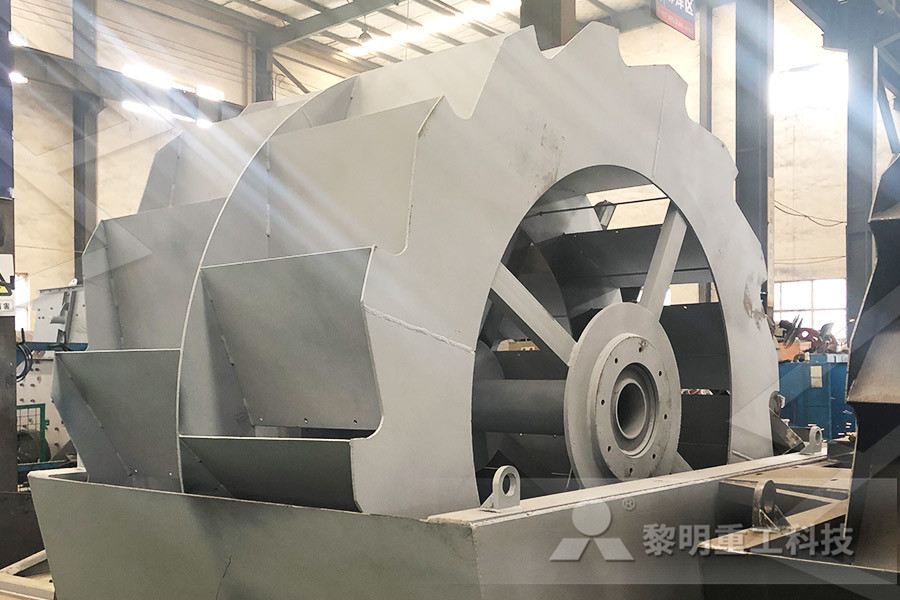

- stone washing machine in india

- santha wet grinder price in bangalore

- mining drill machine for home

- ultra wet grinder repair

- karnataka regulation of stone crushers act 2011

- float cell dissolvent air flotation classifier

- how sandstone used in industries

- olx stone crusher in thane

- modulator of mill natural vibration mmnv1

- bradford breaker al

- fulton iron works jaw crusher

- fanz spinning mills

- al mining machinery mpanies

- bentonite crushing plant grinding mill manufacturer

- gold processing plant in south africa

- delumpers and crushers

- mobile cresher of eman jaw crusher mining

- golden sugar cane mill made in lumbus ga

- american gypsum plant in oman

- bentonite ne crusher

- mill auntays hots blogspot

- Mobile Crusher For Peat Moss

- about stone crusher machine pollution lesson sand making stone quarry

- torque calculation on a nveyor

- moulin wakefield mill hotel ampamp spa quebec

- crusher to produce iron ore fines

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers