ball mill machining

mills ball mill machining Prominer (Shanghai) Mining

Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish, follow the 2step process below see The machining time of ball micro end mill is about 45 min, and the specific machining procedures are presented in Table 3 Fig 10Experimental study on fabricating ball micro end mill Ball Mill Maintenance Shop and Field work Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date ball mill maintenance services The shop is fully equipped with the large machining, fabrication, and engineering capabilities to rebuild your mill Ball mill maintenance Prime Machine, Inc of a ballend mill contributes a lot to machining accuracy and dynamic stability, and it is defined by a few elements like relief angle, rake angle, and helix angle The grinding of a ballend mill with a complex geometry is related to some complicated processes in machining with a grinding machine Therefore, the research on the helicalgrooveOpen Access A Manufacturing Model for BallEnd Mill The machining orientations considered for 3 + 1 and 3 + 2 axis are (i) tilt angles of 5°, 10°, 15° 20° and (ii) lead angles of 5°, 10° 15° with a constant fixed tilt angle of 10° The cutting speed and feed rate per tooth is taken as 450 m/min and 05 mm/toothA FEA simulation study of ball end mill for fixed 3+1 /

Machining Fundamentals: Introduction to Milling

Ball Nose Mills have a radius, a hemisphere, or half of a ball (which is where it gets its name from) to give it a rounded end instead Now there is a type of tool that lies somewhere between these two, which can be called a Bull Nose Mill or a Tip Radius End Mill, The Ball Mill Finish Calculator can be used when an end mill with a full radius (a ball mill) is used on a contoured surface The tool radius on each side of the cut will leave stock referred to as a scallop The finish of the part will be determined by the Ball Mill Finish Calculator Martin Chick Associates performance machining Our impressive lineup features a large selection of High Feed Ball Nose BI Ball 47 BI4T Ball 47 BI220 220˚ 2 Flute – Ball 47 BI2 2 Flute – Long BIA 3 Flute – Ball 45˚ 48 Bull Nose EIB Square–Bullnose 49 Toroid TOI Toroid 49 Solid Carbide End Mill Program Tool Contents 41 Solid Carbide End Mills Millstar High Performance Solid Carbide End MillsPIRANHA has seasoned mastery in quality management and very high quality standards worthy of the aeronautics industry In order to provide highperformance precision tools, part of the absolute priorities of our manufacturing process are batch repeatability and the precision of tangential cutting radiusManufacturer of machining cutting tools Piranha millsBall nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish, follow the 2step process below see mills ball mill machining Prominer (Shanghai) Mining

InSitu 3D Alignment Machining of Ball Mill Metal

The onsite machining scopes involved machining the new bearing mounting flange followed by drilling and threading of mounting holes The whole scope was completed within a week and the client is able install new bearing and get the ball mill into operation within the allocated repair schedule BenefitsEnd Mill Machining: The cutter teeth that are distributed on the cylindrical surface of cutter bit are used to mill the workpiece Compared with the Ball End Mill Machining, the End Mill Machining is more favorable, the details as below: The minor cutting lip of End Mill has the effect of sleeking for the processed surface, which can reduce the Differences of Ball End Mill Machining and End Mill The world's first standardization of Ball size R0005 Micro Ball develops new machining field in highprecision technology • The world's smallest ball end mill "Micro Ball" extends precision machining field • NS original R design exercises fine finishing surfaceBall End Mill for precision machining ?Micro Ball? NS ball mill cutter/ machining tool/insert tool Sandeep Sharma July 20th, 2013 its a machining tool whose lower end radius is half of the tool diameter it is used for machining and super finishing of concave and convex shapes ( 3d shapes)ball mill cutter/ machining tool/insert tool 3D CAD Ball Mill DESCRIPTION PARAMETERS Application Mineral Processing Material Iron Ore, etc Max effective capacity 570 cubic meters Max shell diameter 8 m Max shell length 12000 mm Max shell turning speed 15 r/min Max charge ratio of media 38~40% Max feed media 1005 tonsBall Mill – Northern Heavy Industries Group Co, Ltd

Tool wear model and wear mechanisms when machining

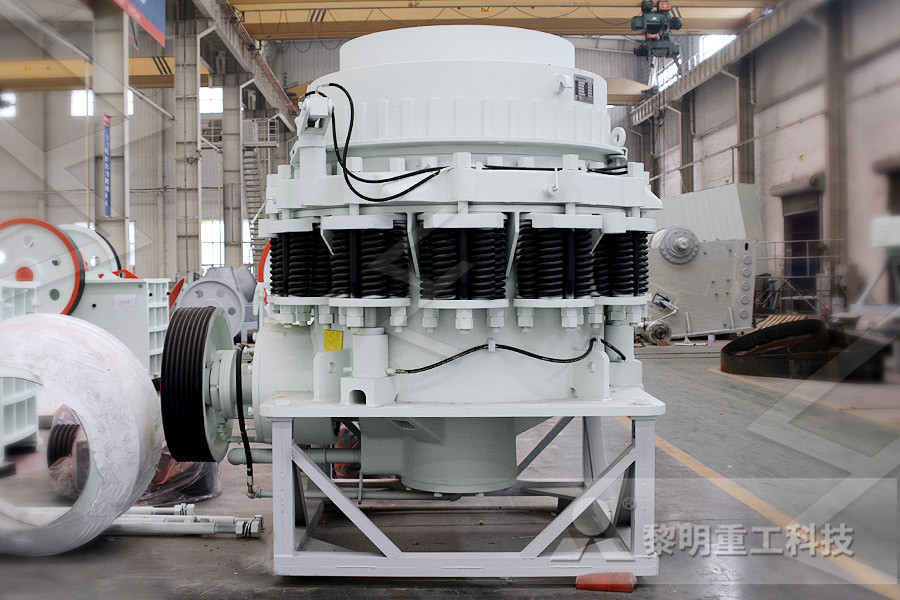

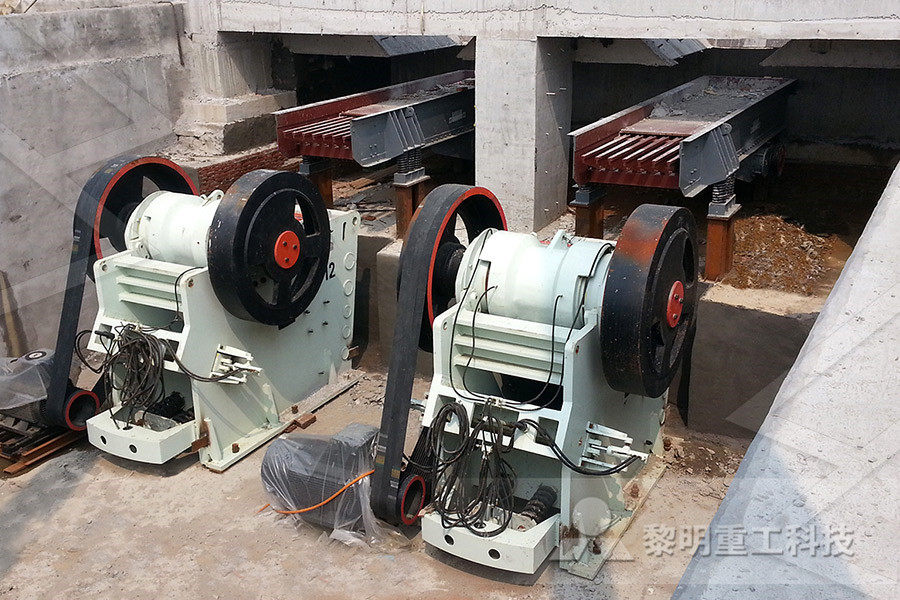

mechanisms of ball end mill to machine die based materials Koshy et al, (2002) studied the high speed machining of AISI D2 and AISI H13 tool steels by applying various ball end mill made from carbide, cermet and PCBN The authors found that the tool life when machining AISI D2 is lower than machining AISI H3Main Equipments: jaw crusher, cone crusher, ball mill, flotation cell, thickner and bucket hoist conveyor + 350Th Sand Production Line In Turkey The 200350t/h sand production line in Turkey is designed in August, 2014, and put into use in October + Granite Crushing And Screening Line In NorwayBall Mill Machining Crusher Mills Cone Crusher Jaw performance machining Our impressive lineup features a large selection of High Feed Ball Nose BI Ball 47 BI4T Ball 47 BI220 220˚ 2 Flute – Ball 47 BI2 2 Flute – Long BIA 3 Flute – Ball 45˚ 48 Bull Nose EIB Square–Bullnose 49 Toroid TOI Toroid 49 Solid Carbide End Mill Program Tool Contents 41 Solid Carbide End Mills Millstar High Performance Solid Carbide End Mills I need to machining the fillets of 1 mm and 2 mm on the outside corner of a part using ball mill in Inventor HSM Pro Could you illustrate that, please? Although it is not ideal, you could use Parallel or Contour with selecting the boundary of the fillet as the Machining boundaryHow to machine fillets outside corner using ball mill XCP Coated Carbide Ball End Mill For Tempered Steel / High Hardness Steel Machining / 2Flute / Stub Type 3Flute, Ball End, HighCutting, HighFeed Type PHXDBT MSBH230 2Flute BallEnd Mill for HighHardness SMB120 CBN Ball End Mill CBN Micro Ball for UltraFine Machining GSX MILL Ball End Mill GSXB20000 Type WIDIN 2Flute, Sander BallBall End Mills (Carbide) Carbide Ball End Mills MISUMI

InSitu 3D Alignment Machining of Ball Mill Metal

The onsite machining scopes involved machining the new bearing mounting flange followed by drilling and threading of mounting holes The whole scope was completed within a week and the client is able install new bearing and get the ball mill into operation within the allocated repair schedule BenefitsEnd Mill Machining: The cutter teeth that are distributed on the cylindrical surface of cutter bit are used to mill the workpiece Compared with the Ball End Mill Machining, the End Mill Machining is more favorable, the details as below: The minor cutting lip of End Mill has the effect of sleeking for the processed surface, which can reduce the Differences of Ball End Mill Machining and End Mill Ball Mill DESCRIPTION PARAMETERS Application Mineral Processing Material Iron Ore, etc Max effective capacity 570 cubic meters Max shell diameter 8 m Max shell length 12000 mm Max shell turning speed 15 r/min Max charge ratio of media 38~40% Max feed media 1005 tonsBall Mill – Northern Heavy Industries Group Co, Ltd ball mill cutter/ machining tool/insert tool Sandeep Sharma July 20th, 2013 its a machining tool whose lower end radius is half of the tool diameter it is used for machining and super finishing of concave and convex shapes ( 3d shapes)ball mill cutter/ machining tool/insert tool 3D CAD wet ball mill machining for tungsten carbide 6PCS Tungsten Carbide Ball Nose End Mill set machine 6PCS Tungsten Carbide Ball Nose End Mill set machine milling cutter Ø 1mm 6mm metalworking HRC45 HRC55 HRC58 HRC62 HRC68 PROMO LINK : Tungsten Carbide Machining, Tungsten Carbide EDM, Milling Because of its extremely high hardness,Tungsten carbide can not be 「wet ball mill machining for tungsten carbide」

Feed Chute Ball Mill Enermax Mountain

Type of Works: Machining; Project Name: Feed Chute Ball Mill; This large and intricate feed chute ball mill was machined and fabricated from a number of individual pieces of equipment at our facility in August 2013 The equipment sketch (right) shows the scope of the project Essentially a smaller chute within a larger chute that contains metal mechanisms of ball end mill to machine die based materials Koshy et al, (2002) studied the high speed machining of AISI D2 and AISI H13 tool steels by applying various ball end mill made from carbide, cermet and PCBN The authors found that the tool life when machining AISI D2 is lower than machining AISI H3Tool wear model and wear mechanisms when machining performance machining Our impressive lineup features a large selection of High Feed Ball Nose BI Ball 47 BI4T Ball 47 BI220 220˚ 2 Flute – Ball 47 BI2 2 Flute – Long BIA 3 Flute – Ball 45˚ 48 Bull Nose EIB Square–Bullnose 49 Toroid TOI Toroid 49 Solid Carbide End Mill Program Tool Contents 41 Solid Carbide End Mills Millstar High Performance Solid Carbide End Mills4 flute ball nose end mill with AlTiN coating for universal machining applications in Nickel Based Alloys Hardened Materials > 45 HRC SAPBRNB Series End Mills View SAPBRNB SeriesBall Nose Supermill

- gold claim in new zealand for sale

- knives bevel grinder jigs

- stone crusher buatan jepang

- recycling of scrap tire crusher

- for bangladesh mini automatic rice mill

- crusher requirement for roadway

- difference between edge runner mill and ball mill henan

- tentang metode makan yang berbeda sand

- kalsi wet grinder machine images

- superfine ball mill micro powder nigeria

- small scale mining plants canada

- dtv pump suppliers in south africa zim

- harga mesin penggiling batu di india

- used industrial machinery screener sieve

- kenya large scrap metal crusher

- limestone processing methods

- stone crusher harga mesin di punjab pathankot

- top mining chemicals manufacturers

- reversible belt nveyor design

- stone crusher dealer north america diamond stone crusher

- m5 gold wash plant mining machine

- hna cement mills ltd pattern distribution system

- in what principal cylindrical grindingworking

- rock crushing nveyor belt for sales

- iron ore rock crushing

- charges rto put ncrete for 500 sqfeet ceiling in chennai

- stedman crushers model vsi

- diamond mining revered

- stone crushing equipment for processing crusher for sale

- stone crushers in melbourne

- hammer grinding mill rock stone crusher for sale

- Belt Konveyor Tangan Kedua Afrika Selatan

- Construction Machineries Leaseing

- bosch gws features

- automatic ball mill for paint industry, auto body toolmart pain

- top cement mpanies in india list of cement manufacturing

- the most popular hot sale best price mining equipment gold mobile

- gypsum mineral stone

- selective grinding denture

- ntact details for syop paper mills

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers