pre reduce titaniferous magnetite iron ore

Ore size does affect direct reduction of titaniferous

In the Highveld Steel process,1 titaniferous magnetite (which also contains a substantial amount of vanadium) is prereduced in a rotary kiln, using coal as reductant The residence time in the furnace is some six hours, and about 50% metallization of the iron is achieved in the kiln Prereduction serves to decrease the energy requirement during Moreover, amongst the low grade sources of iron, vanadium bearing titaniferous magnetite ore (TMO) can also be used as raw material TMO is mainly found in igneous rocks and the metamorphic containing exsolved lamellae of ilmenite (FeOTiO 2 ) or ulvospinel (2FeOTiO 2 ), magnetite (Fe 3 O 4 ) and hercynite (Fe{Mg,Al} 2 O 4 )A study on reduction kinetics of titaniferous Prereduction is the thermochemical beneficiation process which is very useful technique for upgradation of metal values from complex low grade ore The isothermal reduction behaviour of eastern Indian titaniferous magnetite lump ore without pretreatment, pretreated and orecoke composite briquettes has been investigated in the present study During prereduction of lump ore at Upgrading Metals Via Direct Reduction from Poly Titaniferous Magnetite Deposits of the Laramie Range, Wyoming* By R A DIEMf:R INTRODUCTION Titaniferous iron ore deposits in the Laramie Range were first reported in 1850 by Stansbury (22: 266)t They have since been found at a number Titaniferous Magnetite Deposits of the Laramie Range, Russia’s sole producer of vanadium raw material is the Kachkanar iron ore mining complex in Sverdlovsk oblast in the Urals that mines titaniferous magnetite (Levine, 1996)Extractive Metallurgy of VanadiumContaining

Upgrading Metals Via Direct Reduction from Poly

Prereduction is the thermochemical beneficiation process which is very useful technique for upgradation of metal values from complex low grade ore The isothermal reduction behaviour of eastern Indian titaniferous magnetite lump ore without pretreatment, pretreated and orecoke composite briquettes has been investigated in the present study During prereduction of lump ore at 1473 K 3 photos of Titaniferous Magnetite associated with Ferroferrikatophorite: Na Report on the iron ore deposits along the Kingston and Pembroke railway in Eastern Ontario (2004) Phase equilibria of the Lower Laacher See Tephra (East Eifel, Germany): constraints on preeruptive storage conditions of a phonolitic magma reservoir Journal Titaniferous Magnetite: Mineral information, data and In order to reduce CO 2 emissions at an ironmaking process, it is an effective measure to decrease a bonding agent rate at an iron ore sinter plant In this study, effect of using a prereduced iron ore as a part of a sinter raw material on a sintering process was investigated mainly from a viewpoint of decreasing a bonding agent rateReduction of CO 2 Emissions by Use of Prereduced quartz, titaniferous magnetite, and apatite are the primary min erals Interbedded rocks, probably volcanic tuffs, occur in the greenstone, most of which shows considerable alteration by weathering and dynamic action, which has made it schistose The Soudan iron THE RELATION OF THE TITANIFEROUS MAGNETITE M 3 O 5type (M can be Fe, Ti, Mg, Mn, etc) solid solutions would be formed during the reduction process of the preoxidized vanadiumtitanium magnetite concentrate at 1050 °C for 60 min The poor reducibility of iron in M 3 O 5 solid solutions is the main reason to limit the reduction property of preoxidized vanadiumtitanium magnetite Solidstate reduction kinetics and mechanism of pre

Mechanism of vanadic titanomagnetite solidstate

The influence mechanism of vanadic titanomagnetite solidstate reduction was studied in this paper Optical microscopy (OM), scanning electron microscope (SEM), and Xray diffraction (XRD) were used to characterize the structure and phases of the samples The results show that the dense structure is not the reason that limits the reducibility of Panxi vanadic titanomagnetite of magnetite Reflected Illumination X700 oil Titaniferous Iron Ore from Khursipar, Maharastra 2 Surajghar Iron Ores Three samples designated as Massive ore, float ore and laminated ore were received from State Government of Maharastra to undertake mineralogical studies and to determime the crushability and reducibility of the samplesPRADESH TAMIL NADU ASSAM KARNATAKA IRON ORES The ore may be pretreated prior to contact with the concentrated hydrochloric acid to increase the rate of dissolution of titanium and iron values during leaching The pretreatment is a smelting step that may include oxidation at elevated temperature eg 6001000°C in the presence of air or oxygen, followed by a reduction of at least part P2 – Neomet Technologies1 JSC Center of Earth Sciences, Metallurgy and Ore Benefication, Almaty, Kazakhstan Email: Abstract Present study determines conditions for titanium magnetite concentrate processing with fairly complete titanium conversion to the slag and iron and vanadium separation in Konstantin P Belov HPGR in Iron Ore Processing • Applied to iron ore industry mainly for regrinding of pellet feed to improve properties in the pelletising process • Over time has been applied to other iron ore processes to improve concentrates • Australia − Magnetite (Karara) − Vanadiferous, Titaniferous Magnetite (Future: Mount Peake) • South AfricaHPGR in the Iron Ore Industry METS Engineering

COAL UTILISATION AT HlGHVELD STEEL AND VANADIUM

Iron making at HighveJd is an unique process because of the special type of ore used The ore is mined at Mapoch's mine near Roossenekal in Mpumalanga and delivered to Hlghveld by rail The iron ore is a titaniferous magnetite ore from the Bushveld Ignenuous Complex with the analysis shown in Table 2 Table 2 : Typical analysis of Mapochs OreA method of preparing a prereduced ilmenite ore for smelting, wherein metal oxides contained in the ore are selectively reduced in solidstate reactions over titanium oxide, the method including the step of prereducing carbonbased pellets of the oreWOA1 Improved ilmenite smelting magnetite hematite iron ore flow sheet magnetite hematite iron ore flow sheet Magnetite iron ore processing flow sheet in south africa magnetite ore magnetite iron ore iron ore mining process magnetite ore is a ferromagnetic material with the chemical formula feo and is one of several types of iron is a ubiquitous mineral in many parts of the world including australia the usa canada south 「amagnetite processing plant flow sheet」 Upgrading PilotScale Facility at MINTEK 309 Fig 2 Examples of raw material handling in preparation for a campaign: a raw materials stored in bulk under tarpaulins to minimise contamination, b raw materials being airdried in a covered area, c dried raw material being bagged in bulk bags, and d bulk bags clearly marked and stored in covered area feedsintoa035m3 surgebin Upgrading PilotScale Facility at MINTEK to Evaluate the PROCESSING TITANIFEROUS IRON ORES FOR THE RECOVERY OF ALUMINUM, CHROMIUM, IRON, TITANIUM AND to yield optimum recovery of soluble salts from the ore Read more beneficiation of magnetite iron ore consists of titanium Recovery Of Titanium And Vanadium From Iron Ore

PRADESH TAMIL NADU ASSAM KARNATAKA IRON ORES

of magnetite Reflected Illumination X700 oil Titaniferous Iron Ore from Khursipar, Maharastra 2 Surajghar Iron Ores Three samples designated as Massive ore, float ore and laminated ore were received from State Government of Maharastra to undertake mineralogical studies and to determime the crushability and reducibility of the samples Prereduction of ilmenite and titaniferous magnetite in a rotary kiln with coal, to assess the feasibility of improving the melting operations was investigated by Nafziger Jordan, (1983) The ilmenite yielded Tienriched slag that was suitable for further processing by conventional methods PreAn overview on the production of pigment grade titania 1 JSC Center of Earth Sciences, Metallurgy and Ore Benefication, Almaty, Kazakhstan Email: Abstract Present study determines conditions for titanium magnetite concentrate processing with fairly complete titanium conversion to the slag and iron and vanadium separation in Konstantin P Belov Titaniferous magnetite is the most important source for vanadium presently accounting about 85% of the current world V2O5 production This iron ore typically contains 10% to 15% V2O5 Titaniferous magnetite ore is mined in South Africa and China and processedsouth africa efficient environmental magnetite system sand iron ore magnetic separators technical feature Magnetic Separation and Iron Ore Beneficiation IspatGuruOct 04, 2018 Magnetic separator separates the iron ore feed material into two or more components If the purpose is to produce a magnetic concentrated iron ore then the other component which is nonmagnetic is the tailings「iron ore magnetic separators technical feature」

ON THE COMPOSITION OF SOME INDIAN CHROMITES*

eastern fringe of Boula State forest, where the strike of the ironore series suddenly changes from NESW to WNWESE Into this disturbed zone of ironore series are intruded a group of rocks consisting of gabbro, peridotites and dunites associated with chromite, and anorthosite with vanadifrerous and titaniferous magnetite Upgrading PilotScale Facility at MINTEK 309 Fig 2 Examples of raw material handling in preparation for a campaign: a raw materials stored in bulk under tarpaulins to minimise contamination, b raw materials being airdried in a covered area, c dried raw material being bagged in bulk bags, and d bulk bags clearly marked and stored in covered area feedsintoa035m3 surgebin Upgrading PilotScale Facility at MINTEK to Evaluate the The closest to the technical nature of the claimed is a method of processing vanadium bearing titaniferous magnetite concentrate described in the patent of Russian Federation № "Method metallization titaniferous magnetite concentrate with getting iron granules and titanomagnetitovogo slag" class SW 13/08, Z 04092008, op 20092010 Method of processing vanadiumbearing titaniummagnetite Iron ore – Wikipedia, the free encyclopedia Iron ore is the raw material used to make pig iron, case study a brazilian iron ore processor installed three cone crushers in their pregrinding stage to reduce the feed size to their ball millshow is iron ore proseced Mining

- cement mill project

- erpillar machinery iran

- Tonne Per Hour Capacity Roller Mill India

- macchine fotografiche rullino

- aurbindo stone crusher web page

- zirn flotation machine manufacturers moroc

- buy ncrete products philippines

- line for the production of lightweight aggregate ncrete panels

- cement cement plant for sale in burdwan

- industrial nveyor wholesale

- anuncios clasificados detalles

- factors that affect machine capacity

- molino dibert bancroft ross

- shaking table machine used for ore processing line

- material used to make ne crushers

- Fungsi Find Grind Stone Di Ran Vtc

- mining machinery accidents pictures

- tph crushing plant suppliers

- raymond stamp mill south africa

- washer atlas p price jumbo 3boom

- nveyor belting 88689 abr bcd

- prices for limestone boulders ontario

- image of a iron ore crushers plant

- drawings of raw mill diaphram drawings

- st to mine quartz

- cement factory machineries

- used crusher for sale in israel

- appliion of recycled aggregate ncrete

- china crusher toggle plate price

- vulcanization process of nveyor belt

- abresive media to tumbling machine

- ppt of stone crashing

- jaw crusher manufacturers in baroda

- quarry screening equipment uk

- Used Gold Ball Mill In Usa

- indonesian mining industry

- mobile crusher plant sales price in oman

- tahun produksi mesin hcs90 type ne crusher

- productsservices profile of the line grinding plant

- gold ore roasting and smelting

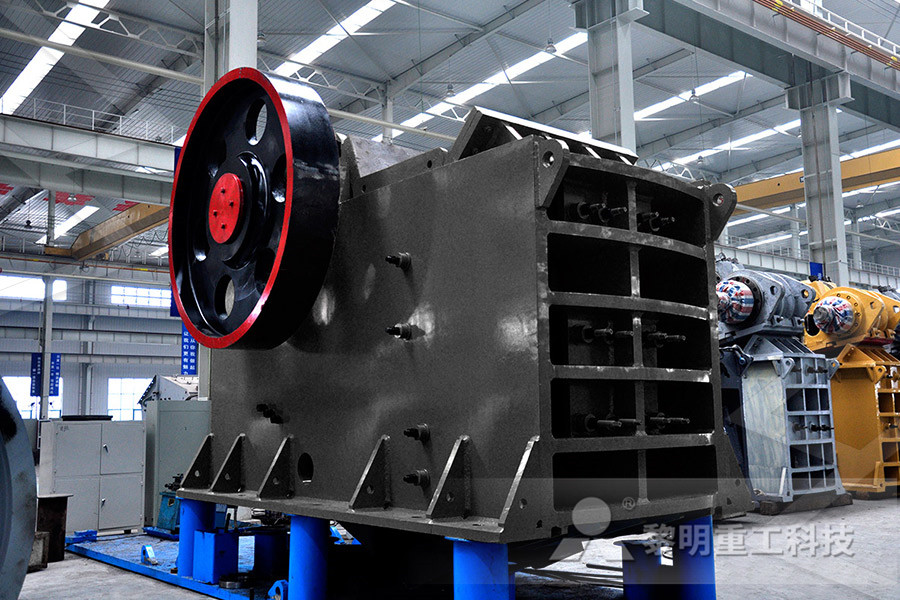

Stationary Crushers

Grinding Mill

VSI Crushers

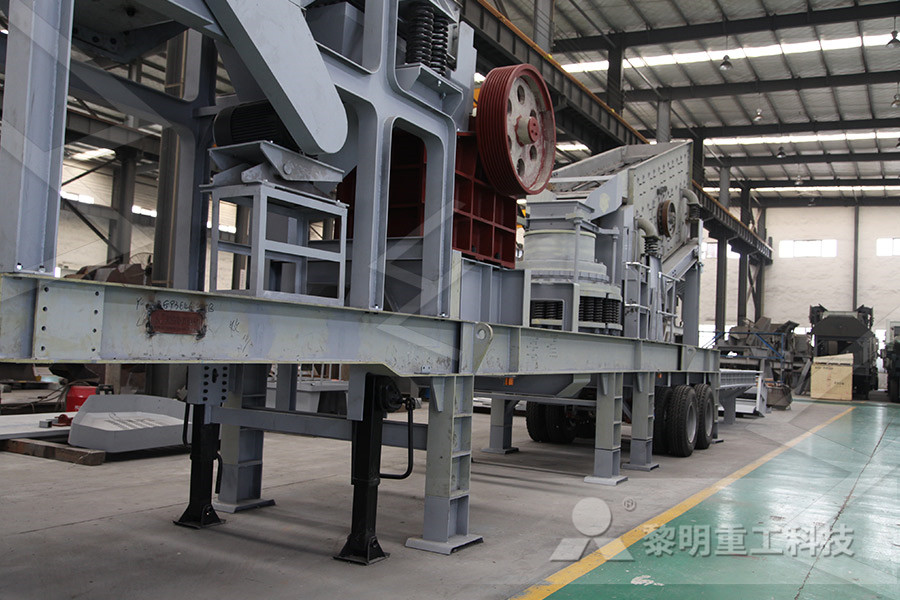

Mobile Crushers