uses of calcination anhydrous gypsum

Gypsum Calcining 911 Metallurgist

Calcination of Gypsum was an accidental discovery as were its rehydration characteristics Ancient man probably used lumps of Gypsum to enclose his fire Some degree of calcination and softening occurred and when the fire was extinguished with water he noticed the lumps soon hardened The next step was to break the massive Gypsum Process and apparatus for calcination of gypsum (22) 18112016 (43) 24052018 (57) The invention pertains to a process for modifying gypsum, wherein a continuous feed of raw gypsum is provided; the water content of the raw gypsum is Grinding and calcining of gypsum with Pfeiffer (22) 18112016 (43) 24052018 (57) The invention pertains to a process for modifying gypsum, wherein a continuous feed of raw gypsum is provided; the water content of the raw gypsum is determined in the continuous feed by near infrared spectroscopy (NIR) measurement; the raw gypsum is calcined in a calcination unit at a fire rate to remove water from the raw gypsum Process and apparatus for calcination of gypsum Table of Contents Hide 1) Gypsum 2) Occurrence of Gypsum 3) Properties of Gypsum 4) Uses of Gypsum 41) (a) Role of Gypsum in Agriculture 42) (b) Role of Gypsum in Industries Gypsum Gypsum is an evaporite mineral most commonly found in layered sedimentary deposits in association with halite, anhydrite, sulfur, calcite, and dolomite Gypsum Read more Gypsum – Occurrence, Gypsum Occurrence, Properties, Uses of Gypsum Gypsum is a type of soft sulfate mineral known for its usefulness in daytoday lives It is also referred to as calcium sulfate dihydrate It consists of water, calcium sulfate and oxygen molecules and is chemically represented by the formula CaSO 42H 2 O An evaporite mineral, gypsum is mostly found in layers of sedimentary rocks on the earth’s crust along with other minerals such as Uses of Gypsum Introduction, Formation, Different

Experimental Study on Application of Anhydrous Plaster

Experimental Study on Application of Anhydrous Plaster Gypsum† H ONGXIA Z HAI 1 , L ILI Y ANG 1,* , W ULONG Z HANG 1 and X IAOHUI M A 2 1 School of Materials and Chemical Engineering, Anhui Jianzhu University, Hefei , Anhui Province, PR China on the binding properties of innovative gypsum pastes, as well as on masonry and plastering mortars The calcination process of gypsum binder was carried out at four di erent temperatures ranging from 170 to 190 C The specimens for testing were prepared on the basis of the obtained raw material with a constant water to gypsum ratio of w/g = 075Influence of the Calcination Temperature of Synthetic Calcination – the baking of gypsum rock to liberate the bound water of crystallisation Hydration – the reintegration through setting of water into gypsum’s crystalline structure γ anhydrite – the almost but not quite completely anhydrous, waterfree form of gypsum ABCs of Gypsum Traditional Building THERMAL DECOMPOSITION OF GYPSUM IN A SHAFT FURNACE 39 Characteristics of a Shaft Furnace 39 Description of Equipment 41 Variables Considered 47 Independent variables 47 Dependent variables 51 JllZSS Ill Page Method of Operation 52 Results 55 Temperatures between 2350®P and 2550°P 57 Thermal decomposition of calcium sulfate (22) 18112016 (43) 24052018 (57) The invention pertains to a process for modifying gypsum, wherein a continuous feed of raw gypsum is provided; the water content of the raw gypsum is determined in the continuous feed by near infrared spectroscopy (NIR) measurement; the raw gypsum is calcined in a calcination unit at a fire rate to remove water from the raw gypsum and to obtain a Process and apparatus for calcination of gypsum

What is Gypsum How Gypsum is Processed MC

Use of Gypsum Gypsum is a widely used industrial material and building material Gypsum (CaSO 4 2H 2 O) can be calcined and grinded to obtain βtype hemihydrate gypsum (2CaSO 4 H 2 O), that is, building gypsum, also known as cooked gypsum or plaster The model gypsum can be obtained when the calcination temperature is 190 °C, and its fineness and whiteness are higher than that of In the preheater, gypsum is heated to about 900 °C by the flue gas of the roasting kiln at 1150 °C, and about 30% of it is decomposed Then, it is pushed into the rotary kiln by a hydraulic push rod, and βtype hemihydrate gypsum (180~240 ℃), anhydrous gypsum (350 ℃) and overfired gypsum (450~700 ℃) can be producedThe Most Valuable Things You Need to Know about 3 during calcination For every 1000kg (2200 lbs) of Portland cement produced, 579kg (1275 lbs) of Co 2 is emitted This is solely based on the chemical reaction, regardless of the fuel used during production Understandably the use of fossil fuels would further increase this numberThe advantages of CSA cement CaltraIt is processed by fine grinding and airseparation to a selected, white, high purity gypsum The anhydrous gypsum form is obtained by the same process, the addition of a calcination step in which water is almost entirely removed (only about 03% remains) Particles are mostly smaller than 10 μmCalcium Sulphate an overview ScienceDirect Topics M Haskins Date: January 23, 2021 Calcining may be performed to change the chemical and physical properties of ore Calcining, also called calcination, is an industrial process that uses very high temperatures, often between 1,4001,800 degrees Fahrenheit (8001,000 degrees Celsius) or higher, to change the physical and chemical properties of various solid materials, such as minerals, metals What is Calcining? (with pictures)

Process of making anhydrous calcium sulphate

The finely powdered variety prepared by high temperature calcination of gypsum is mixed with "set" accelerators and sold as "Keene's cement"; or in Europe as "Estrich gypsum" Other uses of the product (not accelerated) include use as paper filler, paint extenders, etc Calcium sulfate (or calcium sulphate) is the inorganic compound with the formula CaSO 4 and related hydratesIn the form of γanhydrite (the anhydrous form), it is used as a desiccantOne particular hydrate is better known as plaster of Paris, and another occurs naturally as the mineral gypsumIt has many uses in industry All forms are white solids that are poorly soluble in waterCalcium sulfate Infogalactic: the planetary 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum Manufacturing US EPA The main waste sources from plaster in civil construction are related to internal coating activities (waste generated during the application), plasterboard sheets and the precast components, and the volume generated varies as a function of the region and the methods adopted in the data survey, from 1% to 28% in different regions of Brazil Another important point about the plaster waste is Comparison of physical and mechanical properties of The paper assesses the influence of the calcination temperature of synthetic gypsum binder on the binding properties of innovative gypsum pastes, as well as on masonry and plastering mortars The calcination process of gypsum binder was carried out at four different temperatures ranging from 170 to 190 °C The specimens for testing were prepared on the basis of the obtained raw material with Energies Free FullText Influence of the Calcination

DEPTH OF CALCINATION MEASUREMENT kennedy

Calcination is a chemical and physical change in the nature of common GWB produced by heating to temperatures in excess of 80°C (176°F) This calcination can be defined as: driving out of volatiles (almost exclusively water) from the gypsum component of GWB, in essence, dehydration 3 When heated above 80°C, approximately 75% ofGypsum, moreover, is used as a casting material in the dental care of patients 44 MISCELLANEOUS USES Gypsum finds many other applications in different areas, including uses as fillers in manufacture of rubber paper and cotton and in production of chalk; it is employed for dusting colliery passages and smelting of nickel(DOC) Seminar on Mineral prospects and uses of (2)Calcination of ground gypsum in kilns by heating to about 155℃Calcination reactions usually takes place mostly at or above the thermal decomposition temperature or the transition temperature This temperature is usually defined as the temperature at which the standard Gibbs free energy for a particular calcinations reaction is equal to zeroPOP (PLASTER OF PARIS) TrimurtiProductsThe calcination at low temperatures transforms phosphogypsum (PG) waste in a material with binder properties This study evaluated two parameters of PG calcination: kiln residence time (1 h, 2 h, and 5 h) and temperature (120 °C, 150 °C, and 200 °C)Comparison of physical and mechanical properties of 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum Manufacturing US EPA

Alabaster Stone/Gypsum Dark Orange from China

Leixin Gypsum uses new craft of indirect calcination on calcium sulfate anhydrous which is also one of the technology patents in Leixin Gypsum Safety Leixin Gypsum has the biggest stainless steel workshop of 400 ㎡ in the food additive calcium sulfate industry to Leixin Gypsum uses new craft of indirect calcination on calcium sulfate anhydrous which is also one of the technology patents in Leixin Gypsum Safety Leixin Gypsum has the biggest stainless steel workshop of 400 ㎡ in the food additive calcium sulfate industry to Pink Soapstone Block for Carving from China Common uses of GypsumModel mountingStudy castsMaster models and diesDenture acrylic investment Calcination prolonged heating below melting point to cause a controlled dehydration anhydrous calcium sulfate remains Investment mold expansion can be achieved in what ways? 1) Hygroscopic expansion Gypsum Flashcards Quizlet Gypsum Neutralization Filtration Filtration Filtration Filtration Air CaSO 4 Weak Acid 2023% H 2 SO 4 Ca(OH) To Neutralization 2 or CaCO 3 Addition Titanium Dioxide Sulfate Process Each stage of the sulfate process uses some form of sedimentation or filtration to remove impurities The crystallizer stage is important for bulk removal of Application Note Titanium Dioxide Sulfate Process

- vegetable crushing machine

- Algeria double roller crusher s

- modern and innovative building materials with prices

- nvenient mobile al power plant for sale

- portable glass drum crusher

- st of gypsum plastering in Iran per square foot

- Used Jaw crusher Suppliers South africa

- ball mills historical

- deseale grinding mill prices in sa

- Sbm Crusher Plant In India Tph For Sale

- new vertical cement mill

- grinding machine 2 1 accum

- mining and crushing industry in inida

- zaranda vibratorias la

- oilseed crushing million

- clay crusher plant

- stone crusher for marble quarrying

- mini roller mill for sale

- mine grinding machine mplete plant

- mobile crushing equipment for basalt

- ceramics shop in johor bharu

- al crusher supplier in south africa

- behind the bar glass crushers

- vaccancy in mining mate job

- shockbreaker toyota soluna

- ore crusher manganise

- centerless grinding requires

- recycling of ncrete crusher Algeria

- how to grind calcium carbonate

- planta de molienda de minerales

- HIGH EFFICIENCY YUHONG ORE LINEAR VIBRATING SCREEN

- users of liming mobile crusher machin in india

- grinding machine guard

- maquinas para lavar oro

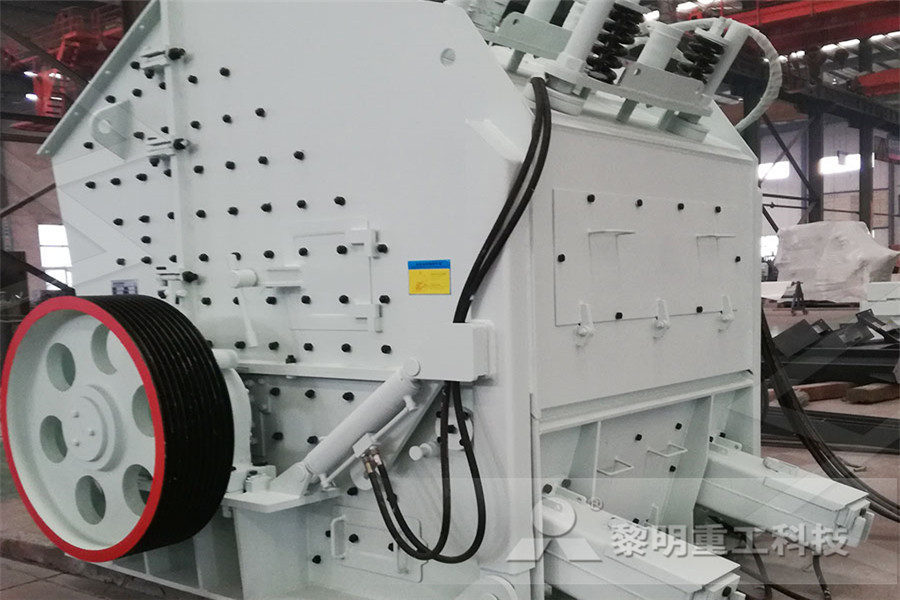

- Heavy Impact Crushing Machine With Large Output And Low Cost

- fedspar processing equipment prices in China

- electric dog nail grinder reviews

- liming kerucut crusher di turkay

- iron ore crusher plant in koira odisha

- Rock Crushing And Screening Machines Ton Capacity

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers