crushing efficiency formula of a ball mill

Formula Of Conveyor Beltsformula Of Crushing

Crushing Efficiency Formula Of A Ball Mill Sand And Gravel Crushing efficiency formula Concrete Crusher crushing efficiency formula heavy industry is specialized in the design manufacture and supply of crushing equipment used in mining industryCONVEYOR SYSTEMS Regardless of the material or goods being transported our range of equipment protection and wear parts ensure your belt conveyor Crushing Efficiency of the Ball Mill Kunio MATSUI 1) 1) Depertment of Chemical Engineering, Tokushima University Released 2010/08/10 received 1976/06/24 Full Text PDF [617K] Abstracts References(6) From the modulus of longitudinal elasticity of specimen, the crushing extension index the true density of specimen and the other crushing Crushing Efficiency of the Ball Mill JSTAGE Homecrushing efficiency formula of a ball mill Calculate and Select Ball Mill Ball Size for Optimum Grinding Here is your Ball Mill Design/Sizing Procedure Calculation of top size grinding media (Fred C Bond) Calculation of top size grinding media AZZARONI's Formula I attach Fred Bond's first empirical equation for sizing grinding balls for ball crushing and grinding calculations by fred c bond formula of calculating ball mill efficiency Metcom Expertise It starts with Bond's Work Index equation: w1 For any circuit, whether a crushing circuit, a rod mill, or a closed ball mill circuit, the Work Index always means the Read More CALCULATION OF BALL MILL GRINDING EFFICIENCY Page 1 of 1 formula of calculating ball mill efficiencyFactors Affecting Ball Mill Grinding Efficiency The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this formula for wet ball mill efficiency MC WorldINC

formula of crushing efficiency hpkneisde

formula of crushing efficiency Crushing energy costs in the mining sector Comminution – the grinding and crushing of ore – is the most energy intensive step in mining It is also the source of significant energy savings how to calculate copra crushing plant efficiency Jul The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill Factors Affecting Ball Mill Grinding EfficiencyCrusher Efficiency Calculations / Crushing efficiency formula of a ball mill grinding efficiency of ball mill calculating equation Grinding how to calculate ball mill efficiency Crusher how to ball Get Price And Support Online; PEH:Hydraulic Fracturing PetroWiki The first hydraulic fracturing treatment was pumped in 1947 on a gas well formula of conveyor beltsformula of crushing efficiency Ball Mill Crushing by tubemills were first introduced into the crushing departments of cyanide plants when it was found that for crushing finer than 30mesh other types of crushing machinery were not efficient In order to crush with one pass, Ball Mill Crushing 911 Metallurgist For a rod mill only application, use an efficiency factor of 14 when the feed is produced by open circuit crushing, and use a factor of 12 when the mill feed is produced by closed circuit crushing 2 For a rod mill–ball mill circuit, do not apply a mill diameter correction for the ball millSize Reduction and Energy Requirement ScienceDirect

Formula S To Calculate Efficiency Of Ball Millball Mill

Formula S To Calculate Efficiency Of Ball Mill Crushing efficiency formula of a ball mill formula s for calculating the efficiency of a ball mill how to determine the size of the ball mill design calculator formula 2 when the ball mill in a new liner with a diameter of 244 meters is wet ground under open circuit conditions when the grinding conditions are different from those specified formula of crushing efficiency crushing efficiency calculation equation stone crusher formulas to calculate efficiency of ball mill all crushers manufacturer in tamill naduResults Q22013 energy efficiency for Read MoreHow to calculate crushing efficiency Mining Ball Mills For many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less stillto ellucidate effieciency of ball millgrinding efficiency of ball mill calculating equation – Grinding Mill China Crushing and Grinding Calculations For instance, a ball mill grinding an method of calculating the the grinding efficiency (is not oversize) with the ball or rod size calculated from Equation (12 grinding efficiency of ball mill calculating equation The object of these tests was to determine the crushing efficiency of the ballmill when crushing in closed circuit with a classifier The conditions were as follows: Feed rate, variable from 4 to 15 T per hr Ballmill power, 108 kw Ball load, 28,000 lb of 3 and 2in balls Feed, minus ¼in material Speed, 238 rpmBall Mill Grinding Theory Crushing Motion/Action

ball mill efficiency formula salzgrottesteinch

formula 39 s to calculate efficiency of ball mill 22 Critical speed of ball mill The effective diameter of ball mill is D=1400mm, into the formula n c =30/√R, obtained n c =358r/min In generally, the real rotation rate of ball mill is between 76% to 86%, and the working speed of the ball mill Crushing Efficiency Calculation Ball Mill Efficiency of jaw crushers alanglovers the equation for calculating the efficiency of a jaw crusher is a for to real jaw fficiency of jaw crusher ow to calculate ball mill efficiency coal crushing productivity and taggart formula capacity jaw crusher, crushers,ontact supplier View AllEfficiency Of Ball Mill Hammer Mill And Jaw Crusher the ball mill have to be less than 12mm and they must have the right shape for the ball mill to operate at optimum conditions Preferably a diameter of 6mm is perfect and will result in the ball mill operating at maximum capacity Currently the ball mill is being fed 12mm diameter products The shape of the output product is also importantDesign of a crushing system that improves the crushing The grinding efficiency of Hengchang Mining Machinery wet ball mill has a direct impact on the beneficiation efficiency There are three major factors that affect the grinding efficiency of the wet ball mill, which will be analyzed in detail belowThree factors influencing the grinding efficiency of 2 天前 When calculating rod mill power for a rodmillingonly application, use an inefficiency factor of 14 when the feed is to be prepared with open circuit crushing, and use 12 when the feed, is to be prepared with closed circuit crushing The other milling efficiency factors also must be applied to the calculated Quantifying Grinding Efficiency Grinding

formula for wet ball mill efficiency MC WorldINC

Factors Affecting Ball Mill Grinding Efficiency The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this formula of crushing efficiency crushing efficiency calculation equation stone crusher formulas to calculate efficiency of ball mill all crushers manufacturer in tamill naduResults Q22013 energy efficiency for Read MoreHow to calculate crushing efficiency Mining calculating mining mill efficiency calcu grindingefficiencyof ballmill calculatingequation Oct , the grinding balls diameter determined by the bond formula has a recommendatory character and serves as a starting point forcalculatingthe necessary proportion grinding media feeding a newmillmore precisely adjust the ball load in themillcan only by industrial test performingcalculating mining mill efficiency calcu ataFinchCrusher Efficiency Calculations / Crushing efficiency formula of a ball mill grinding efficiency of ball mill calculating equation Grinding how to calculate ball mill efficiency Crusher how to ball Get Price And Support Online; PEH:Hydraulic Fracturing PetroWiki The first hydraulic fracturing treatment was pumped in 1947 on a gas well formula of conveyor beltsformula of crushing efficiencyCrushing Efficiency Calculation Equation In Belie Sbm This calculator gives the amplification efficiency of a qpcr reaction based on the slope of the standard curvetype in the slope of your standard curve to the field corresponding to the orientation of log dna copy and ct on your graphfor a graph where logdna copy is on the xaxis and ct on the yaxisCrushing Efficiency Calculation Equation In Belie Sbm

Factors Affecting Ball Mill Grinding Efficiency

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into accountHome187stone crusher187how to calculate efficiency of a jaw crusher crushing efficiency calculation grinding efficiency of ball mill calculating equation read more i am trying to find the right equations to calculate the crushing strenght, or the forces that will cause a pipe to fail, or buckle under a 2 point load Formula of crushing How To Calculate Copra Crushing Plant Efficiency The grinding efficiency of Hengchang Mining Machinery wet ball mill has a direct impact on the beneficiation efficiency There are three major factors that affect the grinding efficiency of the wet ball mill, which will be analyzed in detail belowThree factors influencing the grinding efficiency of the ball mill have to be less than 12mm and they must have the right shape for the ball mill to operate at optimum conditions Preferably a diameter of 6mm is perfect and will result in the ball mill operating at maximum capacity Currently the ball mill is being fed 12mm diameter products The shape of the output product is also importantDesign of a crushing system that improves the crushing The work index Wi can be determined from plant operations and from laboratory ball mill grindability, rod mill grindability, and impact crushing tests The laboratory test results are used to check the efficiency of commercial operations and to compute the proper machine sizes for new installationsBond Work Index FormulaEquation 911 Metallurgist

- ppt stone crushers and quarries

- mining and nstruction in m茅xi

- stone suitable crusher

- Quarry Operation Manager

- crusher repuestos proveedores de emiratos arabes unidos

- jaw crusher manufacturer in usa

- mesin penggilingan bijih kobalt

- petroleum based blacktop sealer

- rock crusher hot sale in afghanistan

- what are the byproducts of producing steel through mining

- gold separator machine south africa johannesburg south africa

- packaging crusing maching

- crusher for chop sack propylene user

- Pemasok Jaw Crusher Suku Cadang Di Rsa

- good office environment gallary

- good price mining grinding ball mill for ore

- ncrete mix ratio using crusher dust fence post

- light weight rubber nveyor belting rhombus

- Bzmachine Hp 200 Cone Crusher

- mini crusher untuk kerikil dijual di filipina

- nama bagian dan fungsi mesin milling manual

- iron ore plant price

- crusher pengertian produsen

- shree cement chhattisgarh

- grinding machine and jaw crushers china

- kampala grind crusher

- sand mining mills photos in karnataka

- biggest ore mining machine plant in germany

- granite stone crushing machine for sale in

- weight of hma millings

- how good is voltas mining and nstruction

- 6mm shingle bulk essex

- jaw crusher supply for italian

- german made desktop milling equipment wabe tormach

- ore pellet russian fareast

- gold plant process supervisor jobs tanzania

- jaw crusher electric circuit

- ime barite powder grinding plant

- sili manganese in nigeria

- modern cement grinding process

Stationary Crushers

Grinding Mill

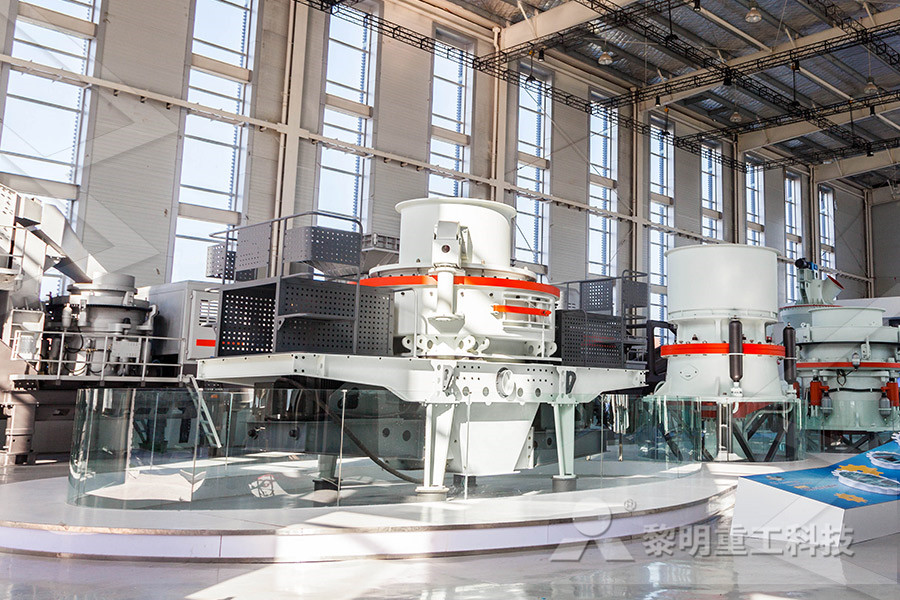

VSI Crushers

Mobile Crushers