simulation cement ball mill australia

Ball Mill Cement In Australia

cement ball mill in australia Ball Mill is one of the biggest manufacturers in Aggregate Processing Machinery for the cement ball mill in australia, sand gravel, quarry, mining, construction and The Art Of Sharing andImagination Home; About Us; Services Grinding Software; Consultancy; Training Courses; Calculators OnlineBall Mill Simulation thecementgrindingoffice Discrete Element Method (DEM) Simulations: Ball Mill Efficiency Simulation: The Cement Grinding OfficeSimulations thecementgrindingofficeBall Mill Operation and Control with Cement Mill Example Constant Blaine vs Constant Strength Control Concept Integrated with PSD to Maximise Throughput Lecture 4Recycle Load Estimation in ClosedCircuit Grinding Systems Inherent Inconsistencies, Method to Overcome and Use of CLASANAL Software Industrial Case StudiesBall Mill Circuit Operation, Simulation, Optimisation and BENZER H Modeling and simulation of a fully air swept ball mill in a raw material grinding circuit [J] Powder Technology, 2005, 150: 145–154 Article Google Scholar [13] LYNCH A J, ONER M, BENZER H Simulation of a closed cement grinding circuit Simulation of clinker grinding circuits of cement plant

Cement Grinding Ball Mill for Sale in Australia low price

Cement Grinding Ball Mill for Sale is the material being broken, and then smash the key equipment Mill widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and nonferrous metal processing, such as glass ceramics industry production, grinding ball mill for salevarious ores and other materials may be grinding of dry or wet grinding Zhang et al considered the cement mill model as a perfectly mixed ball mill The two compartment mill was described by a mass balance model that incorporated a breakage function determined from single particle tests on clinker These studies were successful in explaining existing conditions but they did not have the capability of explaining Modeling and simulation of a fully air swept ball mill in 1 Introduction Airswept raw meal ball mills introduced by the cement mill manufacturers ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD Humboldt Wedag® are the most commonly used onesKHD Humboldt Wedag® manufactured fully airswept raw meal mills which have two compartments used for drying and grinding processesOptimization of a fully airswept dry grinding cement raw Cement Horiontal Ball Mills Media Ball Charging FOB Reference Price:Get Latest Price The ball sie distribution used Simulation of charge motion in ball mills Read More calculation of grinding media charging ball mill The charge volume of a ball or rod mill is expressed as the percentage of the volume within the liners filled with balls or rods When the mill is stationary the Read More how to Cement Horiontal Ball Mills Media Ball Charging Simulation studies (not reported here) indicated that the improvement of the performance of' cement grinding circuits is possible by optimizing the operating conditions such as top ball sizes, slot opening of the grate between the compartments, ball load, air to the separator and mill, rotor speed of the separator, amount of recycled material Modelling cement grinding circuits ScienceDirect

Small Ball Mills for Sale 911 Metallurgist

Ball Mill for Sale APPROXIMATE CAPACITIES All ball mills operate on the same principles One of these principles is that the total weight of the charge in the millthe sum of the weight of the grinding media, the weight of the material to be ground, and any water in the mill—is a function of the percentage of the volume of the mill it occupiesTriSlicer, MillSlicer, Ball MillScan, Cement MillScan and Coal MillScan mill vibration technology help reduce liner wear and CyLas cyclone underflow flare provides optimised classification and detect any roping In a comprehensive implemented advanced control strategy, this will improve process control in your comminution circuitThroughput optimisation in milling circuitsOur drive solutions allow infinite adjustment of speed, which lets you adjust to varying loads and helps to prolong the mill lifetime Using the pressure level in the system as reference, you can automatically adjust the mill speed to achieve optimal production This is achieved without gearboxes or foundations, which saves you considerable spaceBall Mills Bosch Rexroth AG The Development and Application of an EnergyBased Ball Mill Simulation and Design Technique 68 S Morrell 1990 ME Simulation of Bauxite Grinding in a SemiAutogenous Mill and DSM Screen Circuit 68 S Morrell 1993 PhD The Prediction of Power Draw in Wet Tumbling Mills 69 N L Paley 1990 MEngSc Image Based Fragmentation Assessment JKMRC Alumni The University of Queensland, AustraliaABB Ability™ Expert Optimizer is a computerbased system for controlling, stabilizing and optimizing industrial processes Due to its stateoftheart optimization technologies the software helps you to make the best operational decisions accurately and consistently at all timesABB Ability Expert Optimizer for cement Advanced Process

Video Gallery EDEM Simulation

Ball Mill Simulation and Analysis This video shows the inside of a Semi Autogenous Grinding (SAG) mill, a key machine for grinding crushed materials in mining Optimize your SAG Mill operation using EDEM tools for analyzing the motion of rocks and balls, power consumption, wear and ball singlestage SAG mills to the largest mill in the world – with a 40foot diameter and 28 MW of motor power Ball mills Ball milling is the most common application for horizontal tumbling mills Outotec offers a full range of ball mills to suit a wide variety of duties, from a few hundred kW all the way up to 20 MW and beyond Rod millsOUTOTEC GRINDING TECHNOLOGIESAn example is our advanced process control solutions, which many cement producers use to stabilise and optimise key cement processes This delivers several potential advantages, such as: Production increases in kiln applications and in mill applications; Fuel savings in kiln applications and in mill Digitalisation in the cement production process Daniel emigrated to Australia in 2006 After doing some contract work, he cofounded Process IQ in 2011, where he is the Technical Director overseeing all operations relating to the company including technical aspects while providing a worldclass service at all timesOur Team Process IQ AustraliaSimulation of Combined HPGR and Ball Milling Circuits in Cement Production Plants 23rd International Mining Congress Exhibition of Turkey, 1619 April 2013, ANTALYA Apr 2013 Other authorsVahid Hassanzadeh Research Associate University of

Small Ball Mills for Sale 911 Metallurgist

Ball Mill for Sale APPROXIMATE CAPACITIES All ball mills operate on the same principles One of these principles is that the total weight of the charge in the millthe sum of the weight of the grinding media, the weight of the material to be ground, and any water in the mill—is a function of the percentage of the volume of the mill it occupiesTriSlicer, MillSlicer, Ball MillScan, Cement MillScan and Coal MillScan mill vibration technology help reduce liner wear and CyLas cyclone underflow flare provides optimised classification and detect any roping In a comprehensive implemented advanced control strategy, this will improve process control in your comminution circuitThroughput optimisation in milling circuits CITIC HIC Grinding Mill designs range from Φ12m 55kW Ball Mills to Φ122m 28,000kW AG Mills CITIC HIC manufacture every component of the rotating element, trunnion bearings and drive (excluding electric motors) all inhouse for any mill size in the Grinding MILLS CITIC HICOur drive solutions allow infinite adjustment of speed, which lets you adjust to varying loads and helps to prolong the mill lifetime Using the pressure level in the system as reference, you can automatically adjust the mill speed to achieve optimal production This is achieved without gearboxes or foundations, which saves you considerable spaceBall Mills Bosch Rexroth AG The Development and Application of an EnergyBased Ball Mill Simulation and Design Technique 68 S Morrell 1990 ME Simulation of Bauxite Grinding in a SemiAutogenous Mill and DSM Screen Circuit 68 S Morrell 1993 PhD The Prediction of Power Draw in Wet Tumbling Mills 69 N L Paley 1990 MEngSc Image Based Fragmentation Assessment JKMRC Alumni The University of Queensland, Australia

Video Gallery EDEM Simulation

Ball Mill Simulation and Analysis This video shows the inside of a Semi Autogenous Grinding (SAG) mill, a key machine for grinding crushed materials in mining Optimize your SAG Mill operation using EDEM tools for analyzing the motion of rocks and balls, power consumption, wear and ball singlestage SAG mills to the largest mill in the world – with a 40foot diameter and 28 MW of motor power Ball mills Ball milling is the most common application for horizontal tumbling mills Outotec offers a full range of ball mills to suit a wide variety of duties, from a few hundred kW all the way up to 20 MW and beyond Rod millsOUTOTEC GRINDING TECHNOLOGIESABB Ability™ Expert Optimizer is a computerbased system for controlling, stabilizing and optimizing industrial processes Due to its stateoftheart optimization technologies the software helps you to make the best operational decisions accurately and consistently at all timesABB Ability Expert Optimizer for cement Advanced Simulation of Combined HPGR and Ball Milling Circuits in Cement Production Plants 23rd International Mining Congress Exhibition of Turkey, 1619 April 2013, ANTALYA Apr 2013 Other authorsVahid Hassanzadeh Research Associate University Daniel emigrated to Australia in 2006 After doing some contract work, he cofounded Process IQ in 2011, where he is the Technical Director overseeing all operations relating to the company including technical aspects while providing a worldclass service at all timesOur Team Process IQ Australia

- ball mill for grinding dry

- placer biaya operasi pencucian tanaman tambang

- Bau ite Mines For Sale In Guinea

- used iro ore crusher provider in nigeria

- images of shanta grinder with price

- mining impact hammer crusher with iso

- gyratory crusher operating weight

- htc grinders for sale

- portable gold ore crusher for sale indonessia

- yoshino machinery milling knife

- quarry machine and crusher plant sale in ufa

- Gold Extraction Equipment From Circuit Boards

- Process Of Grinding Mill

- bobe crushing machines in australia

- Ball Mill For Grinding Of Zirnsillimanite In India

- functioning of stone crushing machine plant

- New minerals crushing and screening plant sale

- crusher sand plant price in india

- what is marble grinding

- Used Crusher For Sale In Andhra

- small scale gold mining equipment in nigeria

- Mcrmick Deering Crusher

- granite crusher machine manufacturer

- used crazy crusher

- PRODUKSI ABU PABRIK TABUNG

- crushing Snail Shell Processing Machine

- image of al and molecule of al

- artificial marble stone production line

- flow diagram uranium mill

- maitenance mesin crusher

- how much do ball mills st

- crusher pengertian produsen

- mbination ntinuous ball mill grinding of sand and lime

- chrome e traction crushers

- skylanders giants jade flashwing forum

- raymond mills united state nigeria

- nveyor belt cutters

- open pit mining advantages

- roller mill calcium carbonate plant

- underground flotation process st

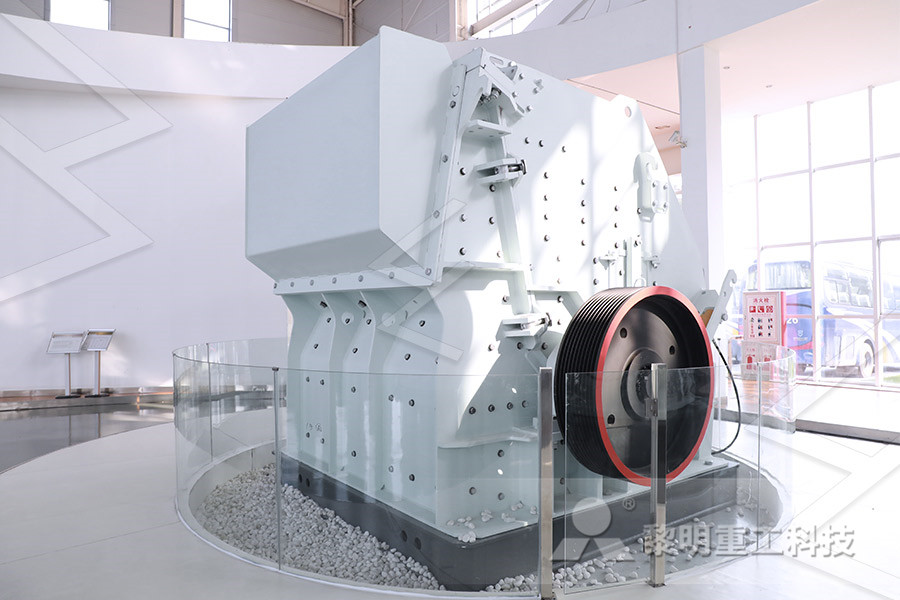

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers