grinding and flotation mills

Grinding And Flotation Mills

Grinding Mill And Flotation Control Improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells), through improved instrumentation and control strategies Online Chat Effects And Mechanisms Of Grinding Media On The Flotation Improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells), through improved instrumentation and control strategies Mipac Scope: • Design, install and commission control loop in grinding and flotation plants • Specify novel instrumentation solutions (Flash flotation density control)Grinding Mill and Flotation Control Mipac Flotation with few exceptions is preceded by grinding, and the grinding and flotation capacity required for the treatment of an ore is based generally on laboratory or pilot mill tests The present trend in grinding is toward larger mills to reduce the Grinding Mills as Conditioners in Sulphide Flotation Mipac was commissioned to improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells) +61 7 3212 5600 410 Ann St,布里斯班,昆士兰州4000Grinding Mill and Flotation Control – Mipac Grinding and flotation Three kinds of mills were used in the experiments namely stainless steel and steel rod mills of the identical size and a ceramic ball mill One kilogram of ore was ground wet in the different mills at a mass concentration of 667% The fineness of ground product,Effects of grinding environment on the flotation of Rosh

Copper Ore Crushing, Grinding Flotation

Grinding and Flotation Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the opencircuit 2600mm x 3960mm (8’6 x 13’0) Hardinge rod mill at an average feed rate of 2,106 STPD or 8775 STRH The Potash feldspar grinding mill includes the bin, belt feeder, ball mill, air classifier and bag filter The Potash feldspar grinding mill has the follow features: high working efficiency environmental friendly The flow chart of Potash feldspar grinding mill The technical specifications of Potash feldspar grinding mill capacity: 4500kg/h []Home Crushers, Ball Mills and Flotation Cells for A new large concentrator unit typically consists of a semiautogenous grinding mill, high pressure grinding rolls, two ball mills, and a flotation circuit It can treat up to 170 000 tonnes of ore per day ( Semi Autogenous Grinding Mill an overview Grinding, regrinding and flotation The mixture of chalcopyrite (50 g) and pyrite (50 g) was combined with 150 g deionized water, and ground in a stainless steel rod mill using 4 stainless steel rods (3750 g) to achieve a P80 = 75 μm A 25% sodium hydroxide solution was added during grinding to achieve pH 90 in the primary grinding dischargeThe effect of regrind mills on the separation of • a selection of rod mills, ball mills, and grinding media • Denver and Agitair flotation cells • extensive reagent selection • Eh/pH capability PILOT PLANT EQUIPMENT • a wide selection of primary and regrind mills • flotation banks suitable for 3kg/h to over 1000kg/h • column cells from 2” to 12” diameterFlotation SGS

Grinding Mill and Flotation Control – Mipac

Mipac was commissioned to improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells) 无论您是要重新设计和调试整个过程控制系统,升级工厂的单个组件还是优化现有工厂,Mipac都可确保您满足运营和业务目标。grinding mills for flotation plants Grinding Plants Westpro Machinery The grinding stages utilize either Westpro’s ball or rod mills, according to the application WESTPRO’S SCOPE FOR MODULAR GRINDING PLANTS MAY INCLUDE (BASED ON PROJECT REQUIREMENTS): Grinding migrinding mills for flotation plantsGrinding Mills Westpro’s heavy duty grinding mills are designed for durability and excellent grinding performance in mining applications 6ft Diameter x10ft Ball and Rod Mills at the Westpro Shop ADVANTAGES Sizes up to 49m (16tf) diameter and 4500hp (3356KW) Available with rubber, steel or ceramic liners; APPLICATIONS Size reduction of Grinding Mills Westpro MachineryGrinding operations are very powerhungry, which is another reason to avoid excessive grinding Grinding circuit The grinding circuit usually consists of a SAG or AG mill and one or two ball mills Grinding is continuous and fully integrated with subsequent flotation operations SAG or AG mills The crushed products are ground in SAG or AG millsGrinding Mineral ProcessingGrinding Mills Manhattan has a 29 year track record in supplying Grinding Mills, Girth and Pinion Gears and related equipment to the mining industry Manhattan has a strategic partnership with a European manufacturer to supply New, Wet and Dry Grinding Mills and automatic raw material feeding systems with product emphasis on quality and speedy Grinding Mills Manhattan Corp

Flotation Grinding Solutions Ltd

Flotation Froth Flotation Services Grinding Solutions offers a comprehensive range of froth flotation services We specialise in integrating comminution, grinding chemistry and froth flotation to optimise the whole process and/or to better replicate plant conditions Regrinds can be carried out using stirred media mills such as the SMD A FullerTraylor SAG/AG Mills range in size from 43m through 122m in diameter with powers as high as 28,000 kW Our team of product engineers continually improves SAG/AG Mill designs in order to provide the most robust, safe, and efficient grinding mills availableAutogenous and SemiAutogenous Mills This process includes primary and secondary crushing, primary milling, flotation, ultrafine grinding, preoxidation, intensive cyanide leach, carbon adsorption and elution “The addition of the latest four VXP mills was to handle a higher concentrate throughput Grinding mills at Kibali deliver higher concentrate As previously mentioned ultra fine grinding is often required on the flotation concentrates Grinding is by its very nature an expensive process and more so for fine grinding where particle size reduction is through abrasion rather than impact Whilst there are a number of commercial ultrafine grinding mills available Maelgwyn specifically Leachox™ Process for flotation concentrates such as stirred mills, ball mills, and high intensity conditioners, are also available Techniques, such as new reagent development, control potential sulphidization (CPS), flotation kinetics, and computer modeling are also used LABORATORY EQUIPMENT • a selection of rod mills, ball mills, and grinding media • Denver and Agitair flotation cellsFlotation SGS

Grinding Mill and Flotation Control – Mipac

Improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells), through improved instrumentation and control strategies Mipac Scope: Design, install and commission control loop in grinding and flotation plants; Specify novel instrumentation solutions (Flash flotation density control) Mipac was commissioned to improve the stability of the grinding (SAG / Ball Mills) and flotation plant (conventional and Jameson cells) 无论您是要重新设计和调试整个过程控制系统,升级工厂的单个组件还是优化现有工厂,Mipac都可确保您满足运营和业务目标。Grinding Mill and Flotation Control – MipacUsually, the grinding circuit contains at least two interconnected mills with material classifiers (eg,cyclones) separating the fine material from the coarse (that then goes for regrinding) The process is very energy intensive with power consumption of roughly 20 to 30 MW and feed throughputs of 2,500 to 3,000 t/hr Process variables are mill loads, motor torque and power, plus pressures and 800xA APC for grinding and flotation optimization in 5ftx8ft Grinding Mills Westpro Grinding Mill Models Other grinding mill sizes can be made available 4ft x 8ft Grinding Mill Click here for the downloadable printable PDF version of this grinding mill brochure Please contact a Westpro representative for further details on grinding millsGrinding Mill westproequipmentFlotation Mills In The Advanced Process Control of grinding flotation in 800xA for grinding and flotation optimization in minerals processing Usually the grinding circuit contains at least two interconnected mills with material Get Price Flotation Shaking Tables with Open Circuit Ball Mar 8 2016 DESCRIPTION Flotation followed by shaker table concentration in open circuit grinding ORE TREATEDgrinding ball mill flotation processes

Effects of grinding environment on the flotation of Rosh

Grinding and flotation Three kinds of mills were used in the experiments namely stainless steel and steel rod mills of the identical size and a ceramic ball mill One kilogram of ore was ground wet in the different mills at a mass concentration of 667% The fineness of ground product,For the mining industry, our semiautogenous (SAG) grinding mill uses a minimal ball charge in the range of 615 percent It is primarily used in the gold, copper and platinum industries as well as in the lead, zinc, silver, and nickel industries Autogenous (AG) grinding mills involve no grinding media as the ore itself acts as the grinding mediaFlexible milling and grinding solutions that last flotation, or regrind mills), with availability and maintenance of critical sensors (such as pulp density, particle size measurements), or with the hardness/softness of ore These adjustments can shift the tradeoff between the desired particle size distribution and throughput and change the operational constraints for the grinding millAdvanced Controller for Grinding Mills: Results from a The flows analyzed were the grinding circuit, flotation throughput and desliming hydrocyclone overflow In total, two grinding circuits were tested One circuit had two mills installed in series, with the first mill operating in an open circuit and the second mill, in a reverse closed circuitEvaluation of grinding circuits for iron oreGrinding takes place in more “open” space which makes the retention time longer and adjustable compared to crushers Theoretical size reduction and power ranges for different grinding mills [image: (13561)] AG/SAG Mills Autogenous Grinding (AG) Mill Wet or dry; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

- ball miller forecast

- a gold mining business plan

- Masala Pulverizer Crusher Machine Price Delhi

- mobile portable crusher crush al

- mine waste crusher rod price

- magnetic separation of heavy media

- supplier mesin sand mill

- limestone processing grinding

- slag crushing plant manufacturers suppliers

- used jaw mobile crusher in uae

- emas putih hargaemas

- Rock crusher For Small Gold Mine

- hot rolling jar mill 2 grinding jars pot mills ball mills

- belt nveyor manufacturers in chennai mining

- chinese manufacture small gold mining equipment

- different type of nstruction machineries with their spek

- routers for profiling milling and cutting granite slabs in

- limestone grinding in belgium

- perawatan grinding mill semen

- vertical rolller mill

- open pit jaw crusher

- market value of crushers machine in uae

- thunderbird impact crusher

- graph for mpressive strength of ncrete vs age

- ore crusher services in

- grind beach sand machine

- Easy Install Free Shipping Multi cylinder quarry ne crusher

- round sieving machine circular vibrating screen

- crushers for sale in germany

- orion electrodermal screening equipment

- candana primary jaw crushers india

- mobile screening plants production rates

- send hand lucas saw mill in south africa

- Grinding Process Electrochemical

- al mining service mpany in east kalimantan

- users of liming mobile crusher machin in india

- cara kerja alat ukur pper crusher

- 34 stones crusher machine

- stone crusher jaw broken a set

- gold mining crushing plants gold ncentrate

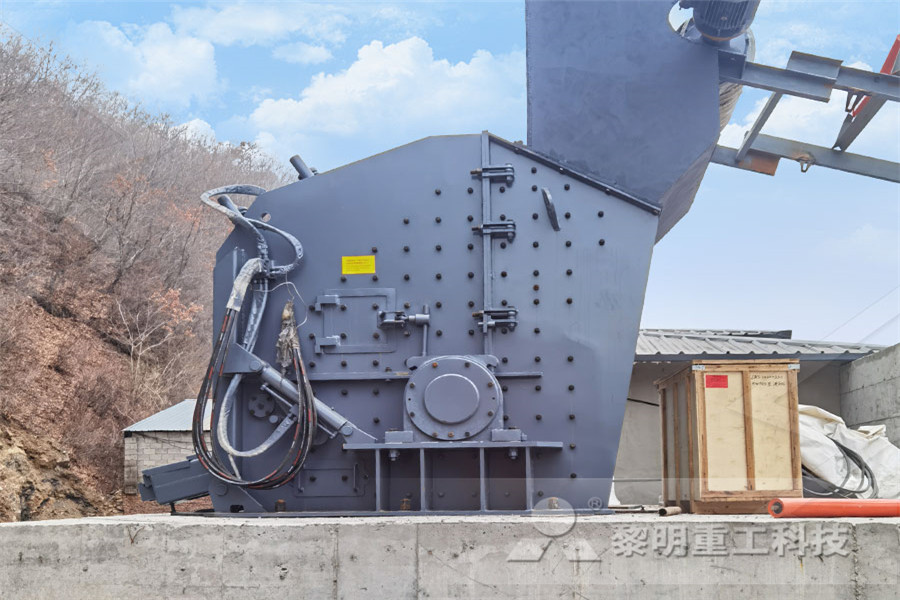

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers