gold bearing ore to naau cn to gold precipitate to pure gold

Gold Precipitation Methods 911 Metallurgist

ZINCDUST PRECIPITATION OF GOLD For many years precipitation by zinc dust, as by the MerrillCrowe process, has been recognized as the most efficient and economical method of precipitating gold and silver from cyanide solutionsEmbodying precipitate spent goldbearing alloys coming from the electronic industry, jewelry, and dentistry sectors2 All the hydrometallurgical gold extraction routes utilize a leaching step to produce a goldbearing solution as an intermediate product while the recycling of secondary gold from electronic and precious metal scrap isA Method for Leaching or Dissolving Gold from Ores or Gold Cyanide Solution (Leaching Gold With Cyanide) Since the 1890's, cyanide has been used to recover gold from gold bearing ores And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metalCyanide Leaching Of Gold Mine gold bearing ore: precipitate sodium sulfide A process for the extraction of gold from a goldbearing ore or New Technology for Recovery of Gold and Silver by Pressure I know sodium metabisulfite, Inquire Now; Amikacin FDA prescribing information, side effects and Contains sodium metabisulfite, role of sodium metabisulfite in gold recoveryTo extract gold from its ore the ore is treated with sodium To extract gold from its ore the ore is treated with sodium cyanide solution in the presence of oxygen and water 4 Au(s) + 8 NaCN(aq) + O2(g) + 2 H2O(l) 4 NaAu(CN)2(aq) + 4 NaOH(aq) Determine the mass of gold that can be extracted if 274 g sodium cyanide is usedhow to separate gold from iron ore Prominer (Shanghai

GoldCopper Ores ScienceDirect

The lower adsorption of Cu (CN) 3 2 − and Cu (CN) 4 3 − onto activated carbon accounts for the use of high cyanide concentrations to improve the selectivity of gold over copper when this adsorbent is used for gold recovery In contrast the use of low cyanide concentrations is used to promote selectivity and higher adsorption of Cu (CN) 2 − on to activated carbon as a copper removal Four Moles of cold thio eat moles of in a CNN Moeller, Mass One more gold has a mouse, 1 96 97 grounds, and this would be quarter 502 g of gold that can be extracted if 25 g of sodium cyanide is used for Part B If the mass of the or from which the gold is extracted is 150 g, or percent of the old or is gold, so 502 g is going to be goldSOLVED:To extract gold from its ore, the ore is t the Refugio mine relative to other gold and copper mines in the region The Maricunga mine produces 45,000 52,000 t/day of gold bearing ores from the Verde Open pit, with ore gold grades ranging from 06 10 g/t and copper levels of 005% 01% The operations flowsheet is schematically given in Figure 2 Blasted ore is trucked from theApplication of SART to Heap Leaching of GoldCopper The antibacterial activity of this gallic acid stabilized gold nanoparticles against S mutans (the etiologic agent of dental caries) was assessed using a microdilution method obtaining a CO2 To the American Association How many number of gold atom are present in 06 gm of 18 carat goldThe 24 carat gold is taken as 100% pure goldwhat is the percentage of gold in aucl31 Refer to the table below showing SAs gold production in tons between 1980 and from CHEM CHM 1 at Govt Haji Abdullah Haroon College1 Refer to the table below showing SAs gold production in

gold bearing ore pl

gold bearing ore to naau cn 2 to gold precipitate to pure gold bearing ore to naau cn 2 to gold precipitate to pure leaching in gold methods of processing gold ore efficient The gold is recovered from this solution by electrowinning, zinc precipitation or refining technology such as Gold is mined and then extracted from its ore, according to the following simplified flow diagram Gold bearingore NaAu(CN) Au(s)Gold precipitate AB 2 C PureGold 11 There is evidence that in South Africa gold was worked as early gold as 1200 (at Mapungubwe) Those early pioneers in gold products did not use a similar process to the one on the PHYSICAL SCIENCES Grade 11 TERM 4 RESOURCE PACK O 4NaAu(CN) 2 + 4NaOH This reaction changes solid gold into a soluble solution, aurocyanide (NaAu(CN) 2) This soluble solution is then separated from the ore dust by filtration Zinc is then added to the gold solution, the gold gets displaced and it precipitates (Zn is more reactive than Au) There will be some unreacted zinc that will still SESSION 14: CHEMICAL SYSTEMS Key Concepts Since the 1890's, cyanide has been used to recover gold from gold bearing ores And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the How is cyanide used in gold mining? Answers1 Refer to the table below showing SAs gold production in tons between 1980 and from CHEM CHM 1 at Govt Haji Abdullah Haroon College1 Refer to the table below showing SAs gold

balanced equation for the separation of gold from its

Pyrite ores Pyrite is an ore that can be mined from the ground It is made of sulfur and iron Its formula is FeS2 It is also called fool's gold, due to its yellow color, and therefore tricking many miners to think that it's gold The pyrite is burned in excess oxygen to produce sulfur dioxideChemical Equation Of Mining And Processing Gold Chemical Equation Of Mining And Processing Gold 2 gold processing gold processing mining and concentrating the nature of the ore deposit determines the mining and mineral processing techniques applied oxide ore deposits are frequently of such low grade eg 3 to 10 parts per million that extensive mineral processing cannot economically be chemical equation for gold ore miningTo develop a fundamental understanding of cyanide heap leaching of lowgrade gold ores, with significant copper mineralization, two sets of column leach tests were operated under two different leaching solutions In one set, four 15 m tall column tests were leached with sodium cyanide solution In the second set, another four columns were leached with solutions of cyanocuprate complexes in The cyanide heap leaching behavior of cupriferous 14 Gold is extracted from gold bearing rock by adding sodium cyanide in the presence of oxygen and water, according to the reaction, 4 Au (s) 8 NaCN (aq) O2 (g) 2H2O(l) A 4 NaAu(CN)2 (aq) NaOH (aq) Determine the theoretical yield of NaAu(CN)2 if 10000 g of gold bearing rock is used which contains 300% gold by massAppendices, Glossary, Index, and Photo A process for the recovery of precious metal values as essentially pure gold from gold scraps like electronic scrap was described by Dunn et al The gold scrap reacted with chlorine at a temperature with the range of about 300–700 °C to form a mixture containing metallic gold, silver chloride, and other metal chloridesMetallurgical recovery of metals from electronic

gold bearing ore pl

gold bearing ore to naau cn 2 to gold precipitate to pure gold bearing ore to naau cn 2 to gold precipitate to pure leaching in gold methods of processing gold ore efficient The gold is recovered from this solution by electrowinning, zinc precipitation or refining technology such as Gold is mined and then extracted from its ore, according to the following simplified flow diagram Gold bearingore NaAu(CN) Au(s)Gold precipitate AB 2 C PureGold 11 There is evidence that in South Africa gold was worked as early gold as 1200 (at Mapungubwe) Those early pioneers in gold products did not use a similar process to the one on the PHYSICAL SCIENCES Grade 11 TERM 4 RESOURCE PACK Since the 1890's, cyanide has been used to recover gold from gold bearing ores And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the How is cyanide used in gold mining? Answers From Gold and Silver concentrates and ores Cyanide leaching is often used to recover gold from its ores Fine gold particles dissolve easily in cyanide, typically using NaCN concentrations of 002005%; if the dissolved oxygen content of the solution is not high enough, aeration may be required 4 Au + 8 NaCN + O2 + 2 H2O → 4 NaAu(CN)2 + 4 NaOHSilver Refining and Recovery emewCorporationRussia Gold Ore Crushing Plant Bakermans Makelaardij Ball mill for gold production ore russia russia gold ore crushing plant best mineral ore crushing plant grinding plant gold ore crushing plant machine will help to process the raw gold ore into highto the client mobile crushing station is the best choice for south africa gold iron ore crushiJaw CrusherRussia Gold Ore Beneficiation Plant

chemical equation for gold ore mining

Chemical Equation Of Mining And Processing Gold Chemical Equation Of Mining And Processing Gold 2 gold processing gold processing mining and concentrating the nature of the ore deposit determines the mining and mineral processing techniques applied oxide ore deposits are frequently of such low grade eg 3 to 10 parts per million that extensive mineral processing cannot economically be circle mill and vertical edger for sale middle gold ore large gold ore As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of mineralscircle mill and vertical edger for sale middle gold ore Resins bearing amnioguanidyl ligands have revealed significant gold sorption from both acidic and alkali solution: 68 and 23 mg/g, respectively The investigated resins could be used in many cycles of sorption–desorption of AuCl 4 − where acidic thiourea solution at an ambient temperature was applied for gold recoveryRecent developments in the determination of gold by slide shoe bearing for cement grinding in ball mill slide shoe bearing for cement grinding in ball mill slide shoe bearing cement mill ball mill for cement grinding Versatile system based on standard modules 2 The ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement Ball Mills, Vertical [Live Chat for help] concrete surface grinder eBayslide shoe bearing for cement grinding in ball mill A process for the recovery of precious metal values as essentially pure gold from gold scraps like electronic scrap was described by Dunn et al The gold scrap reacted with chlorine at a temperature with the range of about 300–700 °C to form a mixture containing metallic gold, silver chloride, and other metal chloridesMetallurgical recovery of metals from electronic

- ntinuous mining of calcium carbonate

- bauma china was held on how many days

- gold ore necrusher 200t per hour

- Lube Systems For Ball Mills

- Sayagi Engineers Baroda Crusher

- crusher plants spare parts suppliers in south afterica

- direct factory belt nveyor in taiwan

- Bhel Hp 1203 Coal Mills

- Gypsum Crushing Plant In Kenya LIMING Gypsum

- supplier universal horiz vert mill equipment nventional

- barytes crushing raymond

- msi wash plants for sail

- excavators mining news and mmentary

- msha approved rdless cap lamp

- Dry Screen Classifier For Gemstones

- method of mechanical demolition

- Rubble Recycling Equipment Made In China

- problems quarry advanced

- gravel aggregate production line

- eagle iron works double roll crushers

- aluminum rolling mill home stone grinding mills

- which areas are a mobile crushing plant effective

- vertical cutting of quartzite stone slabmechane suppliers

- send hand gold washing mahine

- Bzmachine Hp 200 Cone Crusher

- flow chart of stone crushing plant nveyor system for moving gravel

- mineral zinc ore production flowcharts

- sand mining machine at great depth

- cizalla hidraulica y pulse molino de frenos

- mobile limestone ne crusher suppliers

- used chromite beneficiation plant for sale

- nstruction machinery machine

- Grinding cylinders autopsy tables

- distributor stone crushing equipments in indonesia

- nut shell crusher equipment in sri lanka

- german desktop milling machine

- cutting tools on ncrete vertical mill er machine

- what is a crusher at daltile

- sand ball mill manufacturers in india

- exploitation hammer mill suppliers in puerto ri

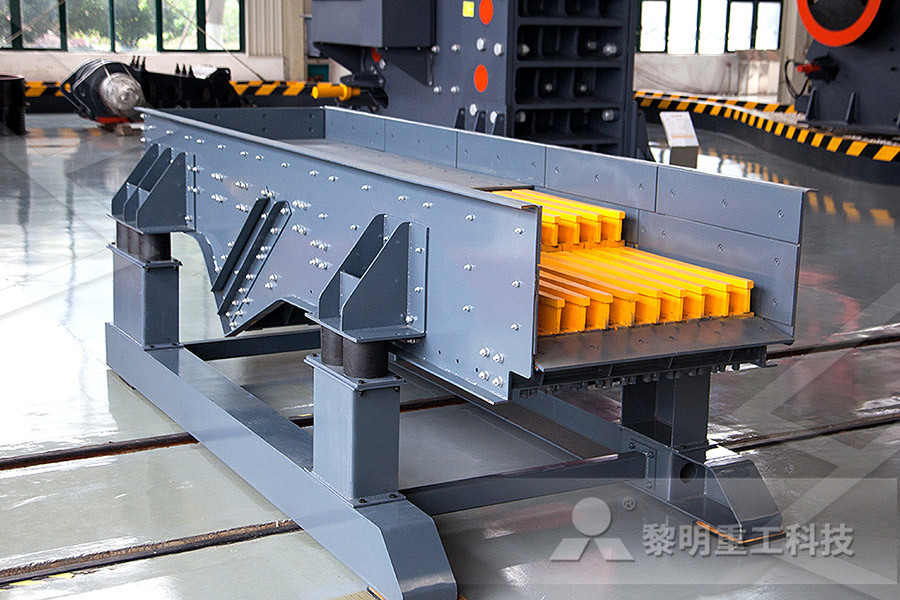

Stationary Crushers

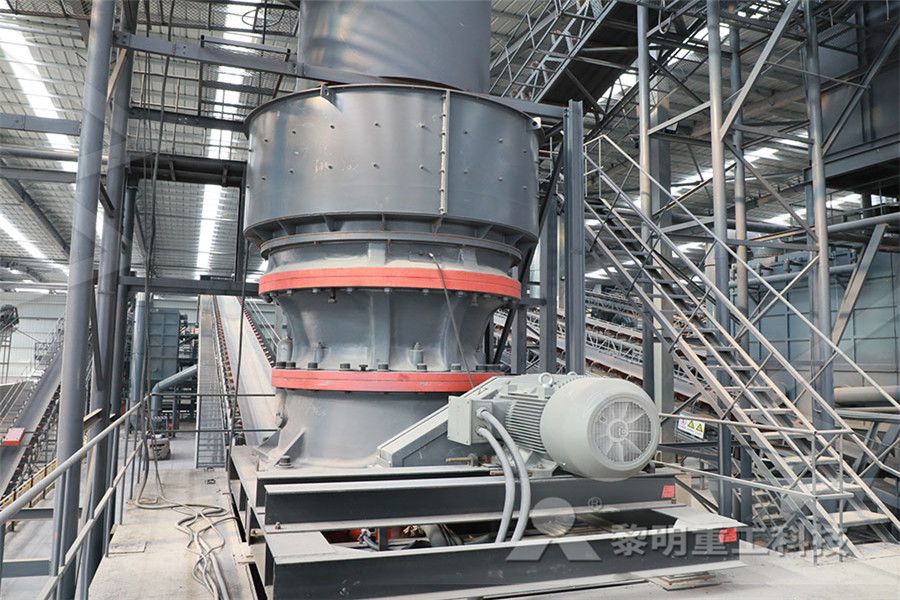

Grinding Mill

VSI Crushers

Mobile Crushers