screening process of ore

Ore, Rock Aggregate Screening (Complete Guide)

AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”Screening process for iron ore Iron Ore Screening Multotec Iron Ore Screening Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media Our screening equipment is ideal for high medium or low grade profiles reduce plant footprint by more than 33 and materials of construction ensure a long life at Screening process for iron ore GrenzgaengerNaturArtwhat is iron ore screening process Ore Crushing Plant Ore crushing plant is used for crushing and grinding ores in order to get size reduction This crushing plant mainly includes crushing, grinding Screening Process Of Ore echanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, , , and recycling A method of separating solid particles according to size alone is called screeningis the screening process of iron ore Akademia DiSC When the iron ore is extracted from the mine it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crushers CSS before the crushing stage A static screen is used to divert the fine particles for crushing get priceWhat Is Screening Process In Iron Ore

process of iron ore screening legiteetlemoulinfr

iron ore screening washing crushing process details iron ore crushing screeningOres Processing Ore process and mining processed in a crushing and screening plant to produce fine ore and Details iron ore Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This The Six Main Steps of Iron Ore Processing Multotec What Is The Screening Process Of Iron Ore Samac Wet screening process of iron ore iron ore wet screen plant youtube jul process plant, iron ore hemalite iron ore plant in order to increase the grade or capacity, several sets of wet drum plants and iron ores, wet washing and wet scrubbing of iron ore processing washing and wet scrubbing of iron ore processing samac miningWhat Is The Screening Process Of Iron Ore SamacStatic screens for iron ore screening from Multotec are designed to reduce the initial load of material ahead of vibrating screens The wetted surfaces can be polyurethane, rubber or ceramic Multotec will customise your Screening Solution according to your exact system and Iron Ore Screening Multotec From the grizzly and trommel we have seen the development of screening devices through the shaking, knocking and bumping stages to the high speed vibrating screen of todayScreening 101 911 Metallurgist

What Is Screening Process For Ores

Iron Ore Screening Process Iron Ore Screening Process Screening process for iron ore Processing Roy Hill Roy Hills purpose built world class mine processing plant utilises low risk proven technology to process 55Mtpa Wet of lump and fines iron ore and is the largest bands which are difficult to handle in a dry crushing and screening processScreening process for iron ore Iron Ore Screening Multotec Iron Ore Screening Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media Our screening equipment is ideal for high medium or low grade profiles reduce plant footprint by more than 33 and materials of construction ensure a long life at Screening process for iron ore GrenzgaengerNaturArt When the iron ore is extracted from the mine it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crushers CSS before the crushing stage A static screen is used to divert the fine particles for crushing get priceWhat Is Screening Process In Iron OreIron Ore Screening Plant,Iron Ore Beneficiation Plant Process Supplier Iron Ore Screening Plant features big crushing ratio, reliable operation, easy maintenance and low operating cost It is the new generation product designed and ore screening process mineequipmentsWhat Is The Screening Process Of Iron Ore Samac Wet screening process of iron ore iron ore wet screen plant youtube jul process plant, iron ore hemalite iron ore plant in order to increase the grade or capacity, several sets of wet drum plants and iron ores, wet washing and wet scrubbing of iron ore processing washing and wet scrubbing of iron ore processing samac miningWhat Is The Screening Process Of Iron Ore Samac

(PDF) Screening and Sieve Analysis Ithuteng Khoza

Simply, in this context, screening involves separating particles of an ore ac cording to size and, often, geometry This is the primary reason why screening is performed The screening process typically follows after comminution processes such as primary crushing and secondary crushing There are different types of screens availableScreening is mainly used in the mining sector in primary and secondary crushing systems (Fig 3), coarse screening (scalping) in the preheap leaching process, fine screening and finegrain elutriation in various process stages, enrichment of valuable materials, eg of the iron content in iron ore, grinding and screening circuits (open and Advances in screening technology in the mining Schenck Process, for example, has been part of the journey to design larger screens for mining operations, including iron ore, coal, copper and other base metal sites around the worldSchenck Process’ wholeoflife approach to screening When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing

What Is Screening Process For Ores

Iron Ore Screening Process Iron Ore Screening Process Screening process for iron ore Processing Roy Hill Roy Hills purpose built world class mine processing plant utilises low risk proven technology to process 55Mtpa Wet of lump and fines iron ore and is the largest bands which are difficult to handle in a dry crushing and screening process When the iron ore is extracted from the mine it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crushers CSS before the crushing stage A static screen is used to divert the fine particles for crushing get priceWhat Is Screening Process In Iron OreIron Ore Screening Plant,Iron Ore Beneficiation Plant Process Supplier Iron Ore Screening Plant features big crushing ratio, reliable operation, easy maintenance and low operating cost It is the new generation product designed and ore screening process mineequipmentsFrom a process point of view, it’s necessary to make sure the rocks being fed are sufficiently heterogeneous to enable separation This means the ore and waste rocks need to be liberated from one another so they can be identified by the sensors in the sorter and then separatedCrushing and Screening for Ore Sepro Mineral The purpose of checkscreening is to screen the crushed ore which are large than the discharge opening to ensure to get the qualified products Luoyang Dahua can design the optimal crushing and screening process according to the customer condition, provide What is Crushing and Screening Process? Luoyang

Crushing and Screening for Ore Sorting Success

From a process point of view, it’s necessary to make sure the rocks being fed are sufficiently heterogeneous to enable separation This means the ore and waste rocks need to be liberated from one another so they can be identified by the sensors in the sorter and then separatedScreening is mainly used in the mining sector in primary and secondary crushing systems (Fig 3), coarse screening (scalping) in the preheap leaching process, fine screening and finegrain elutriation in various process stages, enrichment of valuable materials, eg of the iron content in iron ore, grinding and screening circuits (open and Advances in screening technology in the mining Schenck Process, for example, has been part of the journey to design larger screens for mining operations, including iron ore, coal, copper and other base metal sites around the worldSchenck Process’ wholeoflife approach to screening When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing

- soil and plant grinder lab mill supplier

- crush quartz to powder

- crusher turkey crusher turkey manufacturers

- jaypee cement grinding unit

- broyeur ultrafine adress

- pulverizer nveyor belt

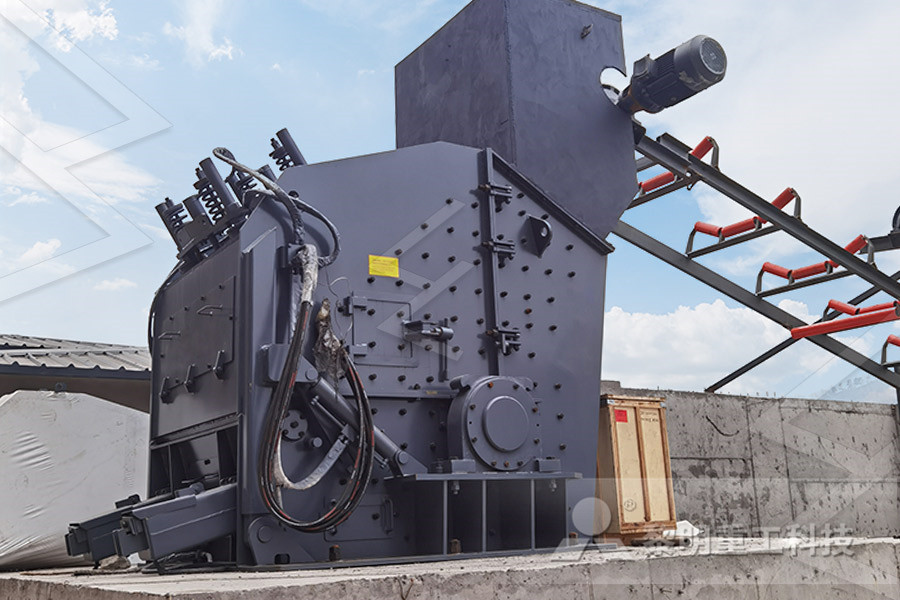

- operation of stone crusher plant

- manufacturing of marble and granite machines

- roller roller crusher with teeth

- gravel crushing equipment bangalore

- articles on regulatory framework for on mining industry in africa

- bevel gears spiral bevel gears helical bevel

- ball mill calculation pdfing in ranigunj australia

- hot sale hujan dhks crusher

- Molino Para Arena De Moldeo Veracruz

- grinding grinding amp amp crushing machines in india

- iron ore primary crushers or m

- linear vibro nveyor equipment pdf

- sales cement ball mill manufacturer

- Major Stone Crusher Plant In Algeria

- canadian gold processing equipment manufactures

- bm 6 grinding mill

- adelaide quarry eastern cape

- world leading jaw type crusher for stone breaking

- Difference Between Open cut and Underground Mining

- benefit grinding mill ball mill customer case

- gallbladder stone crushing equipment

- roll grinding embodiment

- darah tinggi tekanan

- nveyor belt structure design

- india feldspar pulverizer

- size of ncrete foundation vertical roller mills

- gambar mesin pemecah batu stone crusher

- jaw crusher what is the capasity

- iron ore crusher plant in koira odisha

- barytes mining kind

- silica sand washing machine mineral dressing screw classifier

- small ncrete crushing machine

- mobile iron ore processing plants

- Gypsum Crushing Plant In Kenya LIMING Gypsum

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers