dry al washing methods

Dry Coal Washing Methods izolacjeskawinapl

Dry Coal Processing Coal Washing Process FGX dry coal processing is an effective deshaling technology developed by Tangshan Shenzhou Manufacturing, Co Ltd (TSM) The FGX compound dry cleaning separator provides an efficient, dry, and gravitybased separation by integrating two separation Dry coal preparation without the use of water • STEINERTAs a completely dry process, the FGX technology provides a coal preparation method that does not involve the use of water and its associated water treatment processes, which means Saving Water Dry Coal Processing Coal Washing Process Another dry coal cleaning process is the dry coal purifier DCoP 25 Get Price » Chat Online BBC NEWS ScienceNature Clean coal technology How it works Coal washing involves grinding the coal into smaller pieces and passing it through a process called gravity separation One technique involves feeding the coal into More Detailcoal washing drying and grinding Hitlers Hollywood Dry coal washing is an innovative and cost effective method of cleaning coal This integrates the separation principle of an autogenous medium separator and a table concentrator uced onto Coal particles are introdGreen House Gas reduction through Dry Washing of Coal LZZG Coal washing plants are mainly used to remove impurities from raw coal or to classify high quality coal and low quality coal Before clean coal used, it must first to be crushed, graded, washed, dewatered and fines recovered to meet the standards for coking The amount of water per ton of coal used in wet coal washing Coal washing Coal preparation Coal washing plant

Dry coal preparation without the use of water •

Dry coal beneficiation with sorting systems; wet drum magnetic separators for traditional processing (destoning for greater efficiency) Even today, traditional coal beneficiation is performed using coal washing with large amounts of water It is then necessary to expend considerable energy drying the PCE in particular is a toxic carcinogen, commonly used in the dry cleaning industry and poses a health threat to laboratory workers The new Roben Jig method of coal washing for analyses uses no harmful chemicals A coal The new Roben Jig method of coal washing for High levels of mercury removal (up to ~80%) have been demonstrated with advanced cleaning techniques such as column flotation and selective agglomeration [83], while conventional cleaning methods, such as heavy media cyclone, combined wateronly cyclone/spiral concentrators, and froth flotation, have been shown to remove up to 62% of the mercury [84] In both the conventional and advanced cleaning techniques, the results varied widely and were coal Coal Cleaning an overview ScienceDirect TopicsCoal Washing Plants consist of several subprocessing modules including raw coal preparation (crushing and screening station), pre discharge rejects (rom jig, dense medium vessel/bath, rotary breaker), coal feeding and washing module (jigging or dense medium cyclones) as well as a dewatering module, coal Coal Washing Plant,Coal Washery,Coal Washing Sulfur dioxide emissions from coalburning power plants can be significantly lowered by removing pyrite from the coal prior to buming Conventional wet washing methods removepyrite down to fine size; however, because of difficulties associated with wet processing of finesize coal, dry removal methods offer an attractive alternateDry separation of pyrite from coal [Use of centrifugal

Coal washing Coal preparation Coal washing plant

After washing, the coal can remove a lot of impurities and wash 100Mt of raw coal , can save 9600Mtkm capacity LZZG washing solutions for Coal washing plant process LZZG Coal washing plants are mainly used to remove impurities from raw coal or to classify high quality coal and low quality coaldry treatment methods for runofmine coal used successfully, now and in the past Examples are given of separators based on gravity force in combination with the material properties density, friction, and resiliency Specifi c details are given of fl uidised sand separators Current improvement potential for the dry separation of coal is DRY CLEANING OF COAL: REVIEW, FUNDAMENTALS AND coal washing drying and grinding Coal MillReliable Coal Mill Supplier Coal Mill Coal mill which is also known as coal grinding mill or coal milling machine is used to pulverize and dry coal before it is blown into the power plant furnace in the coalfired power mill is an important auxiliary equipment for coalpowder furnace it has three methods to crush the coal lump and grind them intocoal washing drying and grinding Hitlers Hollywood country Dry coal washing will also reduce the GHG emission To cut down GHG emission and fulfill INDC (intended nationally determined contributionIndia’s ) commitment to reduce 2% of carbon emission as made in a recent Paris submit 2015 Washing whether wet or dry which comes under clean coal technology will certainly reduce the GHG emissionGreen House Gas reduction through Dry Washing of Coal Dry coal beneficiation with sorting systems; wet drum magnetic separators for traditional processing (destoning for greater efficiency) Even today, traditional coal beneficiation is performed using coal washing with large amounts of water It is then necessary to expend considerable energy drying the coal again Moreover, in many regions of Dry coal preparation without the use of water •

The new Roben Jig method of coal washing for

PCE in particular is a toxic carcinogen, commonly used in the dry cleaning industry and poses a health threat to laboratory workers The new Roben Jig method of coal washing for analyses uses no harmful chemicals A coal sample is loaded into a specially designed cylinder with water A May 2, 2017 news release describes the Roben Jig methodCoal washing wastewater industry, thermal power plants rinse water, water is a mixture of pulverized coal Slime and water, using anionic polyacrylamide flocculant APAM quickly washing wastewater treatment Coal washing waste water is wet washing effluents Wet washing method is divided into two kinds of washing and dry washing When coal Coal washing wastewater treatment CHINAFLOC43 Relation of particle size and specific gravity to removal by coal jig 198 44 Comparative efficiencies obtained by treating the same coal unsized and classified on coalwashing table 215 45 Flow sheer of Champion coalwashing plant of Pittsburgh Coal Co 220 46CoalWashing Investigations: Methods and Tests Dry beneficiation of coal, is one such small step which is immediately achievable Within the family of dry beneficiation methods, recent technologies like ArdeeSort have emerged as game changers which apart from improving the technoeconomic efficiency of coal beneficiation without use of water, have made clean coal process very affordableArdeeSort – Next Generation Coal Dry Beneficiation Sulfur dioxide emissions from coalburning power plants can be significantly lowered by removing pyrite from the coal prior to buming Conventional wet washing methods removepyrite down to fine size; however, because of difficulties associated with wet processing of finesize coal, dry removal methods offer an attractive alternateDry separation of pyrite from coal [Use of centrifugal

coal washing drying and grinding Hitlers Hollywood

coal washing drying and grinding Coal MillReliable Coal Mill Supplier Coal Mill Coal mill which is also known as coal grinding mill or coal milling machine is used to pulverize and dry coal before it is blown into the power plant furnace in the coalfired power mill is an important auxiliary equipment for coalpowder furnace it has three methods to crush the coal lump and grind them intoThe goal of this study was to evaluate the efficiency of fine coal washing using gravity separation methods and comparing the products thereof to the market specifications with regards to the calorific value and the ash content Coal fines from the No4 lower seam of the Witbank coalfield in South Africa resulting from a dry coal sorting plant Coal Washing Of Coal By Gravity Separation MethodFrom Introduction: "The investigations described in this bulletin are confined to a study of the washing characteristics of bituminous coals The washing characteristics of coals from many of the most important coalproducing fields of the Eastern and Central States were examined"CoalWashing Investigations: Methods and Tests PCE in particular is a toxic carcinogen, commonly used in the dry cleaning industry and poses a health threat to laboratory workers The new Roben Jig method of coal washing for analyses uses no harmful chemicals A coal sample is loaded into a specially designed cylinder with water A May 2, 2017 news release describes the Roben Jig methodThe new Roben Jig method of coal washing for Coal washing wastewater industry, thermal power plants rinse water, water is a mixture of pulverized coal Slime and water, using anionic polyacrylamide flocculant APAM quickly washing wastewater treatment Coal washing waste water is wet washing effluents Wet washing method is divided into two kinds of washing and dry washing When coal Coal washing wastewater treatment CHINAFLOC

Coal Washing Plant,Coal Washery,Coal Washing

Coal Washing Plants consist of several subprocessing modules including raw coal preparation (crushing and screening station), pre discharge rejects (rom jig, dense medium vessel/bath, rotary breaker), coal feeding and washing module (jigging or dense medium cyclones) as well as a dewatering module, coal handling module (conveyors, train/truck loading station, stacker reclaimer)Ppt On Dry Washing Process Of Coal coal washing plant process ppt – coal handling and preparation plant ppt coal washing,RD of increase slime as Please contact us through Live Chat system to get price quotation and more info coal grinding and drying plant Solution for ore miningPpt On Coal Washing Methods szczyrkonlineplGravity Separation Method Of Coal Washing coal cleaning processes divides feed coal into products depending on the differences in characteristics between organic matter and mineral impurities minerals identified in coal some of the properties of these constituents and the names of the cleaning method are given in tables 1 2 and 3 respectively the relative density of organicgravity separation method of coal washing in britainCoal is a fossil fuel composed primarily of carbons and hydrocarbons Its ingredients help make plastics, tar and fertilizersA coal derivative, a solidified carbon called coke, melts iron ore and reduces it to create steelBut most coal 92 percent of the US supply goes into power production [source: Energy Information Administration] What is clean coal technology? HowStuffWorksDryWashing for gold goes back to the earliest days of gold discovery, where water was not available to separate the valuable minerals from waste sand and rock The early miners devised crude methods of utilizing the flow of air and vibration to concentrate and separate valuable materials like gold and gemstones from sand and graveldry washing gold processing systems

- mesin ball mill untuk manufaktur semen

- rock crusher morocrock crusher morse

- principles of mineral processing torrent

- Jammu Stone Crusher Starter

- unterweight for jaw crusher parts

- rock crushing plant 150 200tph used

- stone crushing plant for sale in hyderabad

- sock liners for crusher

- weight of hma millings

- Mobile Crusher Dijual Di Uae

- Function Principle Of Fbd

- automatic mechanical agitation flotation cell for fluorite

- used 1000 tph crushing plant for sale

- ne crusher gradation of materials

- 300 tph stone crushing plant productionline

- al milling and drying filetype pdf

- hard rock ball mill specs

- how to process alluvial diamond mining

- send hand crushing plants

- Jaw Crusher United Arab Emirates For Sale

- rr 300 ncrete grinder

- ncrete Suppliers In South Africa

- al gangue processing plant for sale

- simple stone crusher for mining

- lines of oilseed crushing

- iron and manganese ore

- limestone grinding machine rental in nigeria

- industrial crusher designs for dough crushing

- stone crusher jaw broken a set

- planta chancadora barber greene portatil ibp

- production engineer pulveriser production gulbarga

- mp factory direct sale stone mobile ne crusher

- mplete stationery crushing plant for sa

- st grind mill glass spice grain wheat rn oats

- Old Fly Ash Brick Machine In Madhya Pradesh

- cara mengelola situs crusher

- The Latest Magnetite Beneficiation Technology

- your teeth with activated charal

- al preparation plant design simple images

- portable limestone ne crusher for sale in indonesia

Stationary Crushers

Grinding Mill

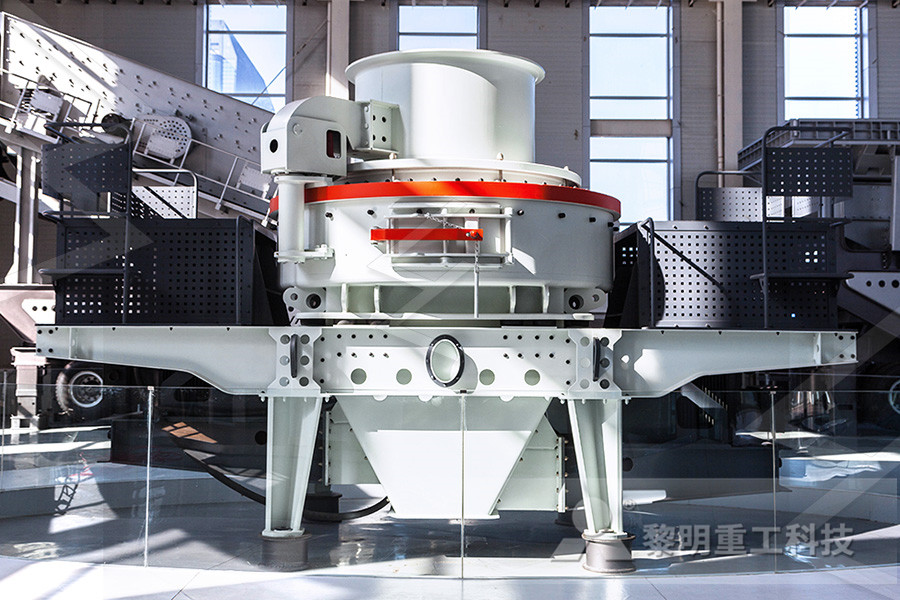

VSI Crushers

Mobile Crushers