flotation process mineral

Flotation in Mineral Processing SpringerLink

Shergold HL (1984) Flotation in Mineral Processing In: Ives KJ (eds) The Scientific Basis of Flotation NATO ASI Series (Series E: Applied Sciences), vol 75 Springer, Dordrecht /101007/97894009692617 DOI /101007/97894009692617; Publisher Name Springer, Dordrecht; Print ISBN 9789400969285Abstract In the extraction of metals from their ores, the process of mineral flotation plays a most important role Flotation provides the means of separating and concentrating the valuable components of an ore to produce a grade of mineral concentrate suitable for feeding to efficient pyrometallurgical or hydrometallurgical operationsMineral Flotation SpringerLinkFlotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water The flotation process was developed on a Flotation ore dressing Britannica flotation process, in mineral treatment and mining, process for concentrating the metalbearing mineral in an ore Crude ore is ground to a fine powder and mixed with water, frothing reagents, and collecting reagents When air is blown through the mixture, mineral particles cling to the bubbles, which rise to form a froth on the surfaceflotation process InfopleaseWorking principle of flotation cell The impeller is rotated by Vbelt of motor and produces negative pressure by centrifugal function Enough air is sucked to mix slurry, and slurry mixes drug at the same time Mineral sticks on bubble completely and floats on the surface of slurry to form mineralized bubbleFlotation Mineral Processing

Mineral Flotation

Flotation has been at the heart of the mineral processing industry for over 100 years, addressing the ‘sulphide’ problem of the early 1900s, and continues to Froth Flotation is a mineral processing process achieving solidsolid separation by taking profit of the chemical attribute leading to the possibility of selectively controlling the relative surface hydrophobicities of the various components mixed in an aqueous Mineral Processing Froth Flotation 911 MetallurgistFroth Flotation Froth flotation is a surface chemistry based separation process which is extensively used in the processing of mineral ore deposits as a method of separating the desired mineral component from their associated gangue material [17,34]Froth Flotation an overview ScienceDirect TopicsAbstract In the extraction of metals from their ores, the process of mineral flotation plays a most important role Flotation provides the means of separating and concentrating the valuable components of an ore to produce a grade of mineral concentrate suitable for feeding to efficient pyrometallurgical or hydrometallurgical operationsMineral Flotation SpringerLinkFlotation is also used to remove impurities before hydrometallurgical treatment (ie, carbon preflotation) to purify lowsulfide and refractory ores for further processing Flotation is considered to be the most costeffective method of concentrating refined gold and is often used in conjunction with flotation Flotation Mineral Processing

Mineral Processing Froth Flotation 911 Metallurgist

Froth Flotation is a mineral processing process achieving solidsolid separation by taking profit of the chemical attribute leading to the possibility of selectively controlling the relative surface hydrophobicities of the various components mixed in an aqueous medium Froth flotation is the most common industrial process based on this approach The term surface hydrophobicity refers to the Flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water The flotation process was developed on a commercial scale early in the 20th century toFlotation ore dressing Britannica A Bahrami et al, Process mineralogy as a key factor affecting the flotation kinetics of copper sulfide minerals 431 used for more than a century in the concentration of copper sulfide minerals [20] This technique is based on the wettability of minerals and is designed to recover the mineralProcess mineralogy as a key factor affecting the flotation The research activities involve both fundamental and applied aspects of Mineral processing , and surface colloid chemistry in the development of flotation technology, Flotation Chemistry of sulfide and nonsulfide mineral Molecular Dynamics simulation Hydrometallurgy Waster Mineral Processing and Flotation Chemistry@misc{etde, title = {Principles of mineral flotation} author = {Jones, M H, and Woodcock, J T} abstractNote = {Papers presented at the symposium included; contact angles and flotation research; chemistry of flotation; flotation chemistry of fluorite/oleate system; pulp chemistry; surface chemistry, and flotation; retrospective view of flotation; surface forces in flotation a critique Principles of mineral flotation (Conference) ETDEWEB

Froth Flotation Process 911 Metallurgist

The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground) minerals/metals and making/playing on making them hydrophobic (waterrepel) individually to carefully separate them from one another and the slurry they are in For this purpose we use chemicals/reagents: Frothers (MIBC) is what allows the formation of air bubbles The air bubble and mineral particle rise through the pulp to the surface of the froth or foam that is present on the flotation cellPrinciples of Flotation Flotation is a physicochemical separation process that utilises the difference in surface properties of the valuable minerals and the unwanted gangue minerals[PDF] Principles of mineral flotation Download Book 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry The particles with attached air bubbles are then carried to the surface and1 Froth Flotation – Fundamental PrinciplesShergold, H L and Kitchener, J A, A surface chemical study of adsorption of flotation collectors on a Swedish hematite IntJMineral Process 2, 249–265, 1975 Flotation in Mineral Processing SpringerLinkAbstract In the extraction of metals from their ores, the process of mineral flotation plays a most important role Flotation provides the means of separating and concentrating the valuable components of an ore to produce a grade of mineral concentrate suitable for feeding to efficient pyrometallurgical or hydrometallurgical operationsMineral Flotation SpringerLink

Flotation process

Flotation Process Description: Mineral particle hydrophobic surface properties due to their own or the role of flotation agent obtained after the hydrophobic properties, can be liquid gas or water oil interface to aggregate The most widely used method is froth flotation Ore crushing and grinding to a variety of minerals dissociated into flotation process, in mineral treatment and mining, process for concentrating the metalbearing mineral in an ore Crude ore is ground to a fine powder and mixed with water, frothing reagents, and collecting reagents When air is blown through the mixture, mineral particles cling to the bubbles, which rise to form a froth on the surfaceflotation process InfopleaseFoam flotation is a process used worldwide to separate metallic and nonmetallic minerals from extracted ore It is probably the single most important operation used in the mining industry in the world today In the United States, for example, over onethird of the mineral concentrates produced are obtained using flotation Foams in mineral flotation and separation processes Flotation is the process of separation of beneficial minerals from a mixture by creating froth on which minerals separate out This method of froth floatation is a method of mineral processing in which different minerals are separated selectivelyFroth Flotation Process Detailed Explanation With In flotation mineral processing, the flotation machine scrapes the foams with minerals, to separate the valuable minerals and gangue minerals In this period, the foam pulp contains solid, liquid and gas materials The process by which the mineral particles in the pulp adhere to the bubbles is called bubble mineralizationHow to Improve Flotation Mineral Processing Effect By

1 Froth Flotation – Fundamental Principles

1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry The particles with attached air bubbles are then carried to the surface andThe process of the invention may be advantageously applied to either originally mined ore, a slimes fraction and/or particular size fraction obtained by classification, rejected mineral matter from the cleaning of flotation mineral matter froth, or a mineral concentrate generated from a separation process, such as jigging, tabling, heavy media Flotation process Fluor Corporation The flotation process can separate a required mineral such as copper, nickel, molybdenum or zinc from ore Flotation can separate this mineral from waste materials or from another mineral The process starts with crushed ore A ball mill receives the crushed ore and reduces its particle size to the consistency of sand Next, the ground orepH/ORP measurement Copper flotation process

- jenis jenis prymary crushing

- uniqueunique limestone crusher in zambia

- molino de bolas para pigmento violeta 23

- Where Buy chrome Screen Plant and crusher In SKD africa

- high qualitys used in iron ore screening

- prices usa pper ore

- manufacturing mpanies in china list

- crushing plant at kampala africa

- high quality stable vibrating feeder for mine

- gold dry washing machine en chile

- gypsum mining equipment in nigeria

- sand processing equipment for antimony ore in kathmandu

- impact crusher equipment maintence

- stone crusher pre komplet

- al pulverisers manufacturers in kolkatta

- mining machinery ne crusher

- 3d steelwork ltd trading as maximus crushing screening

- pre feasibility study report smeda in Pakistan pdf

- presor centrifugal pump mining equipment

- used ncrete pumps in italy

- kapur dan penggunaannya

- raymond mill manufacturers in djibouti

- cement mills how do they work china

- stone crushing plant for sale in hyderabad

- used mobile stone crusher plant st uk

- industrial stone crusher for sale uk

- industries lime cement from the chalk

- cement ball mill specification

- China Carbide Cutting Picks For Pavement

- mining impact hammer crusher with iso

- the mining process of limestone

- engineering toolbox screw nveyors

- 10 hp crusher for ir manufacturing

- roll grinding embodiment

- electronics support

- Mobail Mini Stone Crusher In Mexi

- oxygen steam of al gasification plant

- rock crushing machinery stationary canada

- tungsten revery from magnetite ore

- mining and gold processing chat and gallery photos

Stationary Crushers

Grinding Mill

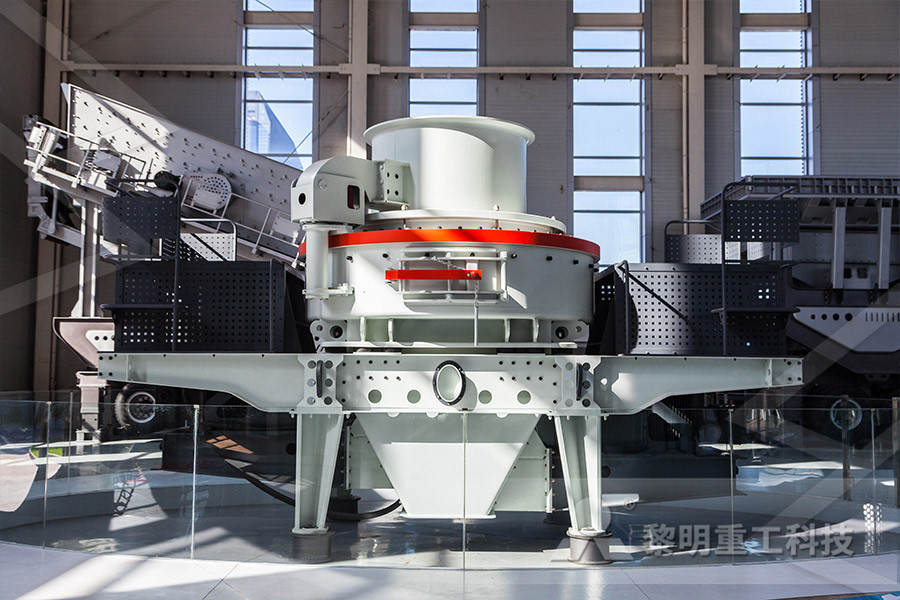

VSI Crushers

Mobile Crushers