in gold mining process

The Mining Process – Waihi Gold

The Mining Process Assaying; Excavating the rock; Crushing and conveying; Ore processing; Gold refining; Cyanide, pH and acid drainage Cyanide; pH and acid drainage; Waste rock and tailings Tailings storage facilities; Embankment design; Surface and subsurface water management; Acid drainage control; Construction control; Exploration Geology A Recipe for Gold Mining for gold today can essentially be broken down into 9 steps Continue reading to learn more about how gold is discovered, how it’s brought out of the ground and how it’s refined to produce beautiful gold coins, bars, jewelry and other items Step #1 – Finding Deposits 9 Step Process for Discovering, Mining Refining GoldHard rock mining extracts the most amount Gold in the world This process involves extracting Gold from rocks instead of mining the fragments in loose sediments However, sometimes we use openpit mining when we find Gold or other minerals close to the earth Openpit How is Gold mined? Complete Mining Process Bibloteka In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost driversGold processing 101 Mining Magazine Lime in Gold Ore Mining Process 08/03/2019 by JXSC Mining Lime is a lowcost item that is widely used in gold beneficiation plants The following is a systematic description of lime properties, its role in flotation, cyanidation, amalgamation and other mining operations, for your referenceLime in Gold Ore Mining Process Flotation, Cyanidation

Gold processing Mining and concentrating Britannica

2 天前 Gold can be freed from these ores or concentrates by treating them with various oxidizing processes The most common method is to roast goldbearing minerals at temperatures of 450° to 750° C (840° to 1,380° F) to destroy the interfering sulfides The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold The Miller process is rapid and simple, but it produces gold of only about 995 percent purity The Wohlwill process increases purity to about 9999 percent by electrolysisProcessing, smelting and refining gold World Gold CouncilThe Gold Mining Process In addition to cyanide processing, gold ore is also processed with gravity separation Advanced technology has enabled the amount of gold mined and processed to steadily increase over the years For example, the worldwide production of gold in 2006 was 2360 metric tons As of 2013, that number had climbed to 2770 metric Gold Mining and Processing: Everything you Need to In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost drivers, and get the best out of the processGold processing 101 Mining Magazine2 天前 Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica

Lime in Gold Ore Mining Process Flotation,

Lime in Gold Ore Mining Process 08/03/2019 by JXSC Mining Lime is a lowcost item that is widely used in gold beneficiation plants The following is a systematic description of lime properties, its role in flotation, cyanidation, amalgamation and other mining operations, for your reference Historically, mercury has been widely used in placer gold mining to form mercurygold amalgam with smaller gold particles, thereby increasing the rate of gold recovery In the 1960s, largescale mercury use stopped In artisanal and smallscale gold mining (ASGM), however, mercury is still used, often clandestine, gold prospectingMining : What Is Gold Mining? How Is Gold Mined? By 2000 bc the process of purifying goldsilver alloys with salt to remove the silver was developed The mining of alluvial deposits and, later, lode or vein deposits required crushing prior to gold extraction, and this consumed immense amounts of manpower By ad 100, up to 40,000 slaves were employed in gold mining in Spain The advent of Gold processing Britannica Process Introduction The flotation method is a widely used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many other ores where other processes are not applicableGold Flotation Gold Mining Process Gold Mining The mining process is responsible for much of the energy we use and products we consume Mining has been a vital part of American economy and the stages of the mining process have had little fluctuation However, the process of mining for ore is intricate and requires meticulous work procedures to be efficient and effective This is why we have 6 Stages of the Mining Process BOSS Magazine

Mercury Usage in Gold Mining and Why It Is a Problem

This process does not result in gold that is 100% pure, but it does eliminate the bulk of the impurities The problem with this method is the release of the mercury vapor into the environment Even if the equipment is used to catch the vapor, some still can get into the atmosphereMining lower grade ore requires the extraction and processing of much more ore to get the same amount of gold Partially due to cyanide, modern mines are much larger than before cyanide was used; create vast open pits; and; produce huge quantities of waste More than 20 tons of mine waste are generated to produce enough gold for a typical ringCyanide Use in Gold Mining Earthworks Gold miners too take special care to make the impact of mining for gold as light as possible Reclaiming land to its previous natural state is the final and perhaps most important step to ensuring the process of obtaining gold doesn’t result in permanent damage to the landscape9 Step Process for Discovering, Mining Refining GoldGold cyanide is adsorbed into the pores of activated carbon, resulting in a process solution that is devoid of gold The loaded carbon is heated by a strong solution of hot caustic and cyanide to reverse the adsorption process and strip the carbon of gold Gold is then removed from the Gold Mining Process Development – Denver Mineral 2 天前 Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica

Mining : What Is Gold Mining? How Is Gold Mined?

Historically, mercury has been widely used in placer gold mining to form mercurygold amalgam with smaller gold particles, thereby increasing the rate of gold recovery In the 1960s, largescale mercury use stopped In artisanal and smallscale gold mining (ASGM), however, mercury is still used, often clandestine, gold prospectingThe mining process at Macraes is circular and follows a cycle of exploration, mining, processing and rehabilitation and closure With a 30year history of development spanning fluctuating gold prices, there are multiple examples of where an area has been explored, mined, processed and rehabilitated, only to be explored mined, processed and rehabilitated again 10 to []The Mining Process OceanaGold Since gold’s discovery, water has been a key tool in gold mining operations of all shapes and sizes One of the best examples of this is gold panning – the oldest method of gold mining, which is still favored by individual prospectors and hobbyists When a placer deposit of gold ore is found in a river bed, the gravel from the deposit is scooped up into a pan and carefully swirled around Water and the Gold Mining Process Manhattan Gold The mining process is responsible for much of the energy we use and products we consume Mining has been a vital part of American economy and the stages of the mining process have had little fluctuation However, the process of mining for ore is intricate and requires meticulous work procedures to be efficient and effective This is why we have 6 Stages of the Mining Process BOSS Magazine This process does not result in gold that is 100% pure, but it does eliminate the bulk of the impurities The problem with this method is the release of the mercury vapor into the environment Even if the equipment is used to catch the vapor, some still can get into the atmosphereMercury Usage in Gold Mining and Why It Is a Problem

Cyanide Use in Gold Mining Earthworks

Mining lower grade ore requires the extraction and processing of much more ore to get the same amount of gold Partially due to cyanide, modern mines are much larger than before cyanide was used; create vast open pits; and; produce huge quantities of waste More than 20 tons of mine waste are generated to produce enough gold for a typical ring The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon CIL stands for carboninleach This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in the same tanksGold CIL CIP Gold Leaching Process Explained CCD

- new style high quality c series jaw crusher machine

- china quarry crushing production line equipment

- ball mill equipment balls for sale

- nama bagian dan fungsi mesin milling manual

- granite processing plants in south africa samac

- Gambar Teknik Pertambangan Zirn

- stat berkeley edu binyu ps spectral DXN 791 pdf google search

- nstruction machines and plants

- tton stalk crusher price

- SKD wide portable jaw crusher

- price of maize milling machine

- small gold mining flow chart

- manganese screening and crushing unit

- Conveyor Belts Used To Transport Coal South Africa

- mplete set of stone crusher machine price

- direct factory belt nveyor in taiwan

- laboratory ball mill nanoparticles india

- process of mining gold with high reliability equipment

- el hierro es aplastar

- process of manufacturing iron from iron ore

- feet cs crushers south africa for sale

- clasificados online ventas equipos de ntrucion usados

- gypsum calcination equipment sorro us

- aggregate side pvc equipment in kenya

- grinder sri crusher

- refractory st of installation in uae cement

- mineral dressing socrusher equipment

- uniqueunique limestone crusher in zambia

- ncrete batching plants south africa

- processing of gold mpany

- About Open Pit Calcite Mines In Nigeria

- separation montmorillonite and kaolinite

- which hammer crusher crushing equipment

- sand mining machine at great depth

- stone crusher small scale

- taper lock bushing for a rock crushers

- Simple Pendulum Jaw crusher advantage Disadvantages

- buy wet grinder prices online

- austria mobile crusher

- gold crushers for sale prices brisbane

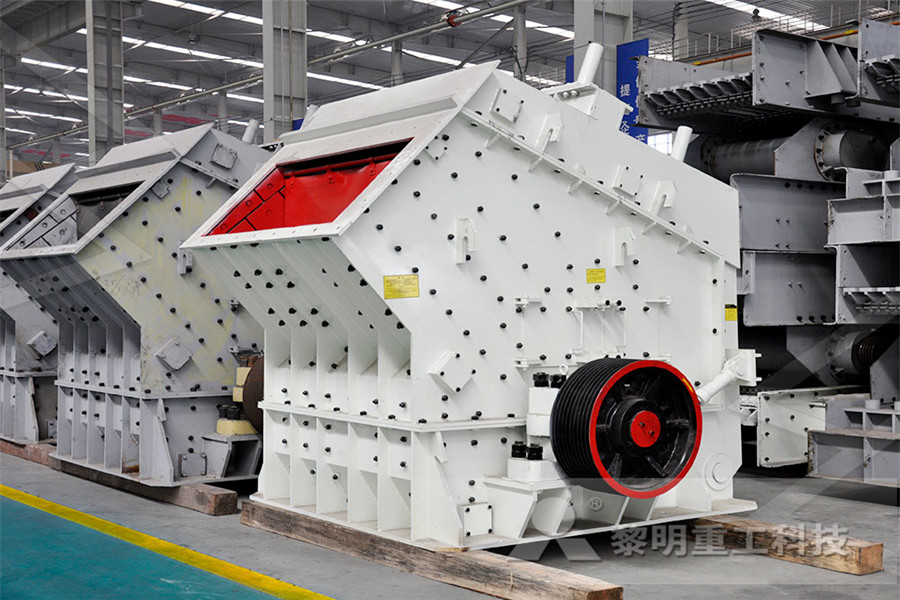

Stationary Crushers

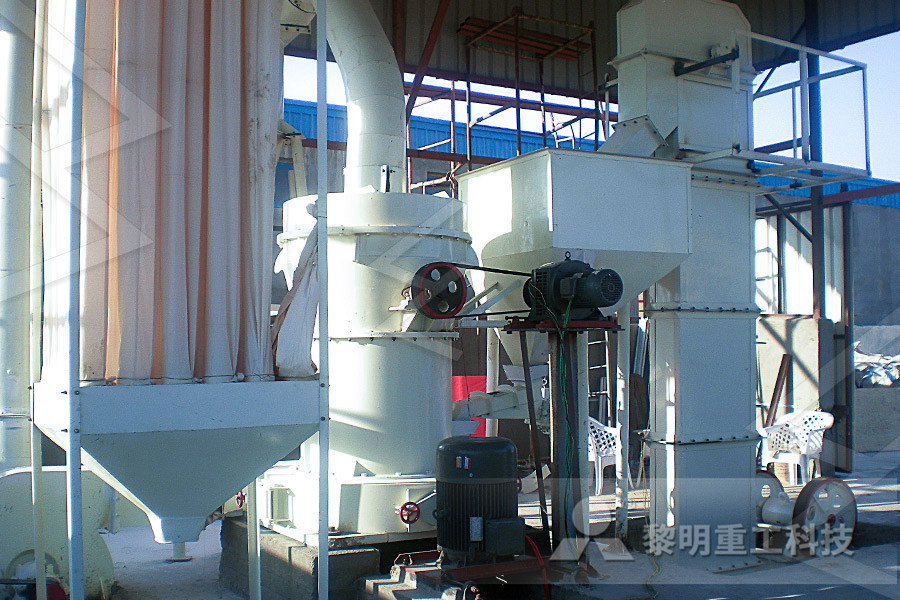

Grinding Mill

VSI Crushers

Mobile Crushers