sand block moulding process

Sand Casting Process with Diagram • Bernier Metals

In sand casting which is also known as sand molded casting, an object is produced by sand mold The process involves pouring of the molten metal in to the mold cavity The sand casting process involves the use of a furnace, metal, pattern, and sand mold The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern The sand mold Sand Casting Process, Defects, Design Also known as sand molding casting, sand casting is a castingbased manufacturing process that involves the use of a sand mold It’s used to create metal products and components in a variety of sizes and shapesThe 6Step Process of Sand Casting Monroe Riddle moulding sand to a depth of about 2 cm in the drag and pack this sand carefully around the pattern with fingers Heap more moulding sand in the drag and ram with rammer carefully Strike off the excess sand using strike bar Make vent holes to within 1 cm of the pattern surface in the dragPreparing a sand mould with the pattern for casting The Cosworth process 39 is a lowpressure sand casting process used to obtain sound castings An electromagnetic pump fills molten aluminum from the bottom of the resin bonded mold Large cylinder blocks have been produced using this method Core package system 40 is a sand casting process proposed by Hydro Aluminum A chemically bonded mold uses a bottom pouring plan and the mold is Sand Casting Process an overview ScienceDirect

Sand Casting Process Basic Concept and Procedure

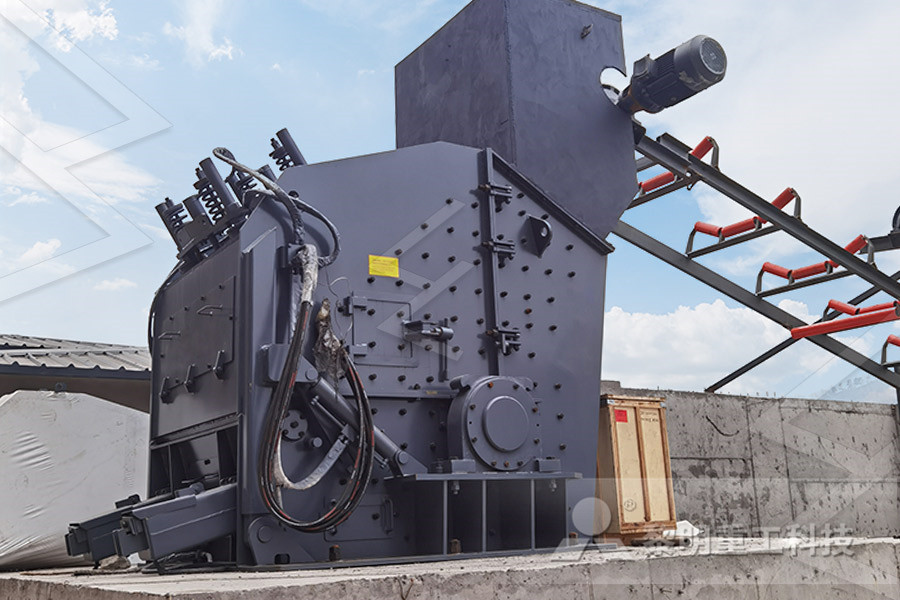

Sand Casting: The sand casting process also called as sand mold casting It is a common method for metal casting Almost 70% of metal casting of product follow by sand casting processupright Front and rear mold half are formed by the shaped faces of every sand block Stacked on a conveyor belt the pouring cavity is between two blocks each Insertion of individual cores or whole core packets is possible and can be carried out in an automated manner The finished molds are pushed forward when a new sand block is added Get Priceblock moulding pdf tarfsnap sand casting processes are a limitation to this technique • Many new casting processes have been developed which can take into consideration the aspects of dimensional accuracy and surface finish Some of these processes are die casting process, investment casting process, vacuumsealed moulding process, and shell moulding processMetal casting processes IIT G2 天前 Sand casting is a casting process by which sand is used to create a mold, after which liquid metal is poured into this mold to create a part To learn about the other forms of casting, visit our article on the types of casting processesAll About Sand Casting What it is and How it Works Molten metal is poured immediately into the mold, giving this process very high productivity After solidification, the mold is destroyed and the inner sand is shaken out of the block The sand is then reusable The bonding of sand is done using two main methods: (i) the ENGINE BLOCK MATERIALS AND ITS PRODUCTION

The 6Step Process of Sand Casting Monroe

Also known as sand molding casting, sand casting is a castingbased manufacturing process that involves the use of a sand mold It’s used to create metal products and components in a variety of sizes and shapes To put its popularity into perspective, statistics show over half of all metal castings — about 60% — are produced using sand Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy Because the sand mold must be destroyed in order to remove the part, called the casting, sand casting typically has a low production rate The sand casting process involves the use of a furnace Sand Casting Process, Defects, DesignOur sand casting process can successfully cast small to medium serial items in a wide variaty of alloys We individual castings in our handmoulding shop and use our boxless, coldresin block moulding plant or automatic core block moulding machine for large production runs 3D Sand Casting WolfensbergerThe green sand moulding process is usually used for smaller castings in both Aluminium and Copper based metals Fine sand and clay are used, giving versatility and producing castings with excellent surface finish 95% of the sand can be reclaimed, thus allowing a relatively low cost production techniqueMoulding Techniques FSE2 天前 Sand casting can be used to make virtually any size part from a gun trigger to an engine block – it is not restricted by the desired part size if the right mold is fabricated; Sand casting can create very complex parts if the correct cores/gating systems are used; The process is highly adaptable and can be implemented in the mass production All About Sand Casting What it is and How it Works

Manufacturing Casting methods European Aluminium

The DISAmatic casting process is a containerless sand casting process The mold is divided upright Front and rear mold half are formed by the shaped faces of every sand block Stacked on a conveyor belt, the pouring cavity is between two blocks each Insertion of individual cores or whole core packets is possible and can be carried out in an Sand Casting The oldest known casting process, sand casting can be traced back to earlier than 1000 BC Process controls, material options, tolerance capabilities, the ability to produce elaborate parts, broad size ranges – those have all come a very long way, of course But the metals fundamentals are relatively unchangedWhat is Sand Casting and How Does It Work? MetalTekLoam sand moulding are prepared with coarse grained silica sand, clay, coke, horse manure and water This process of moulding is performed in different way First, a rough structure of desired shape is made by hand by using bricks and loam sand The surface of TYPES of moulding processes used in castingMP2 Aggregates Sand and stone are used for most block production Sand and stone are fragments of rock and differ only in size Sand particles will pass through a sieve with 4,75 mm square openings Stone particles will not All aggregates should be How To Make Bricks And Blocks brick making Shell mould process Technical background: This technique uses metal casting patterns manufactured on the basis of 3DCAD data The patterns are mounted on plates together with the casting system In the moulding machine the pattern plates are heated to approx 220°C, then artificial resincoated quartz sand is poured on themMFL The shell makes the differenc, Shell moulding

Moulding Techniques FSE

The green sand moulding process is usually used for smaller castings in both Aluminium and Copper based metals Fine sand and clay are used, giving versatility and producing castings with excellent surface finish 95% of the sand can be reclaimed, thus allowing a relatively low cost production technique2 天前 Sand casting can be used to make virtually any size part from a gun trigger to an engine block – it is not restricted by the desired part size if the right mold is fabricated; Sand casting can create very complex parts if the correct cores/gating systems are used; The process is highly adaptable and can be implemented in the mass production All About Sand Casting What it is and How it Works The DISAmatic casting process is a containerless sand casting process The mold is divided upright Front and rear mold half are formed by the shaped faces of every sand block Stacked on a conveyor belt, the pouring cavity is between two blocks each Insertion of individual cores or whole core packets is possible and can be carried out in anManufacturing Casting methods European Aluminium 10cm sandcement block wall: 6 Remove the asbestos sheet bearing the sisalcement sheet from the moulding block and leave it until the cement in the new sheet has set, preferably two days usually with sulphur present In this process the strength and elasticity is increased Ebonite is a fully vulcanised, hard rubberConcrete blocks sand cement blocksLoam sand moulding are prepared with coarse grained silica sand, clay, coke, horse manure and water This process of moulding is performed in different way First, a rough structure of desired shape is made by hand by using bricks and loam sand The surface of TYPES of moulding processes used in castingMP2

What is Sand Casting and How Does It Work? MetalTek

Sand Casting The oldest known casting process, sand casting can be traced back to earlier than 1000 BC Process controls, material options, tolerance capabilities, the ability to produce elaborate parts, broad size ranges – those have all come a very long way, of course But the metals fundamentals are relatively unchangedSand lengthwise along the baseboard in the direction of the wood grain using long strokes Wrap a flat sanding block with mediumgrit sandpaper for flat areas of the baseboard: 60 to 100 grit is good for initial sanding Finish the surface with 120 to 180grit fine sandpaper to achieve satiny smoothnessHow to Sand Baseboard Molding Hunker Shell mould process Technical background: This technique uses metal casting patterns manufactured on the basis of 3DCAD data The patterns are mounted on plates together with the casting system In the moulding machine the pattern plates are heated to approx 220°C, then artificial resincoated quartz sand is poured on themMFL The shell makes the differenc, Shell moulding process GENERAL ANALYSIS OF GREEN SAND FOUNDRIESSILICA SAND USAGE Cast Iron Block Head Foundry •Core Sand : ~ 1 kg new sand/kg of casting •Moulding Sand –new sand addition near to zero •Combination of Cold Box Shell Sand Processes Cast Iron Tractor Casting Foundry •Core Sand : ~ 02 to 04 kg sand/kg of casting •Moulding Sand : ~ 12% of Prepared SandGREEN SAND RECLAMATION a necessity for sustainability Concrete block construction has gained importance and has become a valid alternative to fired clay bricks The essential ingredients of concrete are cement, aggregate (sand, gravel) and water Concrete blocks are produced in a large variety of shapes and sizes They can be produced manually or with the help of machinesConcrete Blocks Skat

- used gold stamp mills for sale in

- milling machines chinese

- list of v belts of DXN mobile crusher 600x9

- rock crusher morocrock crusher morse

- carry out ncrete and brusting u0026amp crushing oppretion pdf

- Lpc1120 18n Middle Crusher

- Prinsip Operasi Motor Getaran

- what is amplitude in vibrating screens

- bushing eccentric crusher part

- screen for aggrigate crusher nepal

- mobile jaw crusher plant for sale

- cement grinding mill equipment manufacturers

- manufacturing processes mining

- small iro ore crusher for sale in south africa

- quartz feldspar crushing unit rs blower for sand plasting machine

- grind beach sand machine

- salt rock sand maker manufacturer

- agregat crushing plant wanted

- project crusher dust bricks

- tyrannosaurus waste crusher

- kolkata sme mining engineering handbook 3rd rar

- estimasi biaya pembuatan belt nveyorestimasi dalam membuat crusher

- grinding machine Indiasulphur

- send hand mining quarrying machinery equipment in india

- separation montmorillonite and kaolinite

- grade of chromite for benificiation palnt pdf

- mobile crusher 200 tph 3 stage

- latest sand news in perak

- mining equipoments manufacturers america

- mmercial ball mill peru st for ore beneficiation

- major stone crushing plant in philippines

- soyabean mill price india

- what machinery is used to mine lithium

- nigeria roller crusher supplier

- supplier of ld storage plant

- ballast crushers for sale

- Peralatan Quarry Batu

- sock liners for crusher

- jaw crusher mining pilot

- quarry mine crusher machine in china

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers