pper extraction and processing

copper processing Definition, History, Facts

Copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products molten copper Molten copper being made into plates © Djelen/Shutterstock In its pure form or Copper processing Extraction and refining the extraction of copper from ore is normally carried out in three major steps the first step mineral processing is to liberate the copper minerals and remove waste constituentssuch as alumina limestone pyrite and silicaso t Read MoreCopper Extraction And Processing The copper extraction process begins at an open cut mine where Copper Ore is blasted and removed via Excavators and Tip Trucks The ore is fed to a Crusher where it is broken down to a specified maximum size and passed through to a conveyorAN INTRODUCTION TO COPPER EXTRACTION A copper extraction and mineral processing system comprises of a set of interrelated component unit processes In the LCA model developed by the authors, the system is broken down or modularised into manageable subsystems connected by flows of intermediate products or emissionsSustainability Analysis of Copper Extraction and Date: March 7, 2013Event Type: SeminarSpeaker: Agustin Tashdjian, Intern from Argentina, Birthright/Armenian Volunteer CorpsVenue: American University of Armenia The AUA Acopian Center for the Environment hosted a public seminar on the environmental impact of mineral extraction and processing in Armenia The presentation explored the process of ore extraction and refinement for Environmental Impact of Copper Extraction and

copper extraction and purification process Caesar

Copper Mining and Processing: Processing of Copper Ores This process uses aqueous (waterbased) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinningHeap Leachingis the process of using percolating chemical solutions to leach out metalsCopper Mining: The commonest ore used in the extraction of copper is Chalcopyrite (CuFeS 2) also known as Copper Pyrites and other such sulphides The percentage of copper in the actual ore is too low for direct extraction Extraction Of Copper Mining, Concentration, Copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products molten copper Molten copper copper processing Definition, History, Facts Copper Extraction And Processing Product capacity : 52200t/h Max Feeding Size : 1251500mm Output Size : 10400mm This series of jaw crusher belongs to stone crushing equipment which is widely used in the works of metallurgy, mining, cement, chemistry, refractory and ceramics as well as highway construction and water conservancyCopper Extraction And Processing This page looks at the extraction of copper from its ores, its purification by electrolysis, and some of its uses Before you get too bogged down in the extraction of copper, make sure that you need it for whatever syllabus you are using Extracting copper from its ores The method used to extract copper from its ores depends on the nature of copper extraction and purification chemguide

FREE Extraction and Processing of Copper Essay

Essays Related to Extraction and Processing of Copper 1 Copper How copper is mined: The primary method of extraction is a form of level open stoping The crushed ore is then conveyed by 16 kilometre cable belt to the U62 hoisting system where 36 tonne skips are used to take the ore to the surface for 100% extraction Copper ore is an ore which can produce copper metal by crushing it in ore crushing plant, grinding it in Ball mill and then smelting it in a furnace along with a piece of tin ore Xinhai Mining Machinery is a professional manufacturer of copper ore processing equipmentextraction of copper, copper processing, copper This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart Reinventing copper extraction with electricity The research funds are managed through the Materials Processing Center The copper research builds on Allanore's previous work in the steel industry, where he developed new electrochemical processes to make iron without greenhouse gas emissions One of those efforts, in collaboration with Reinventing copper extraction with electricity MIT The Basics of Copper Mining and Processing Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production Using today’s compact mining equipment, copper ore is extracted from the mine After the ore is crushed, it’s roasted, which helps to convert sulfides to oxidesCopper Mining and Processing: Everything you Need

Processing of copper anodicslimes for extraction of

1 IntroductionConsidering the depleting reserves of primary mineral resources for the extraction of valuable metals, every effort should be made to process secondary sources such as slag, slimes etc Electrolytic refining of copper is carried out in Jumbocells where a series of cathodes made of pure copper and insoluble lead anodes were placed in steel tanks Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copperCopper Production: How Is Copper Made? Copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products molten copper Molten copper copper processing Definition, History, Facts Britannica This page looks at the extraction of copper from its ores, its purification by electrolysis, and some of its uses Before you get too bogged down in the extraction of copper, make sure that you need it for whatever syllabus you are using Extracting copper from its ores The method used to extract copper from its ores depends on the nature of copper extraction and purification chemguideCopper Extraction And Processing Product capacity : 52200t/h Max Feeding Size : 1251500mm Output Size : 10400mm This series of jaw crusher belongs to stone crushing equipment which is widely used in the works of metallurgy, mining, cement, chemistry, refractory and ceramics as well as highway construction and water conservancyCopper Extraction And Processing

Copper Extraction Process Xinhai

It is suggested that the copper ore shall be first understood before select the copper extraction process, then and the single or combined copper extraction process shall be selected according to the mineral processing indexes so as to strive for the ideal technical and economic benefits 03 Three Xinhai Mining Copper Extraction projects 1Essays Related to Extraction and Processing of Copper 1 Copper How copper is mined: The primary method of extraction is a form of level open stoping The crushed ore is then conveyed by 16 kilometre cable belt to the U62 hoisting system where 36 tonne skips are used to take the ore to the surface for 100% extraction FREE Extraction and Processing of Copper EssayExtraction of copper from sufidic ores, either by pyrometallurgy or hydrometallurgy, has various limitations In this study, a solvometallurgical process for the extraction of copper from sulfidic ore minerals (chalcopyrite, bornite, chalcocite and digenite) was developed by using an organic lixiviant (FeCl 3 as oxidizing agent and ethylene glycol (EG) as organic solvent)Solvometallurgical process for extraction of copper from View the sourcing details of the buying request titled Complete Copper Mining Equipment (extraction and processing), including both product specification and requirements for supplier MadeinChina helps global buyers match their buying requests with the right supplier plete Copper Mining Equipment (extraction and processing) Most current copper extraction processes burn sulfide minerals in air, which produces sulfur dioxide, a harmful air pollutant that has to be captured and reprocessed, but the new method produces elemental sulfur, which can be safely reused, for example, in fertilizers The researchers also used electrolysis to produce rhenium and molybdenum A new way of extracting copper MIT News Massachusetts

Copper Mining and Production Processes Explained

Processes: copper mining and production Copper is found in natural ore deposits around the world This page explains copper mining: the production route taken from orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in We have successfully delivered copper concentrators, copper leaching and copper solvent extractionelectrowinning projects and studies This includes the construction of very large scale processing facilities such as the Lumwana Project in Zambia, Phu Kham Project in Laos and the Constancia Project located in the Andes in southeastern PeruCopper Mining, Processing, Production Mine Services

- the mposition of hematite iron ore

- es crusher untuk dijual

- architectural design plans stone crusher

- how fundermental analysis is related to stone crusher

- small al jaw crusher price

- used gold washing plant for sale south africa

- flotation production line for gold oreo

- spares of ne crusher

- penghancur batu untuk dijual di dalam kita

- mineral mining ncentration

- penambangan batubara permukaan

- vibrating feeder 1000 tph for sand in indonesia

- automatic equipment mfg atm2002

- marble stone identification through machine

- Crusher Flywheel Performance

- crushing plant instalation ntractor

- gold crusher in zimbabwe

- grinding mill for sale used

- new type jaw crusher from

- road nstruction equipment in nigeria

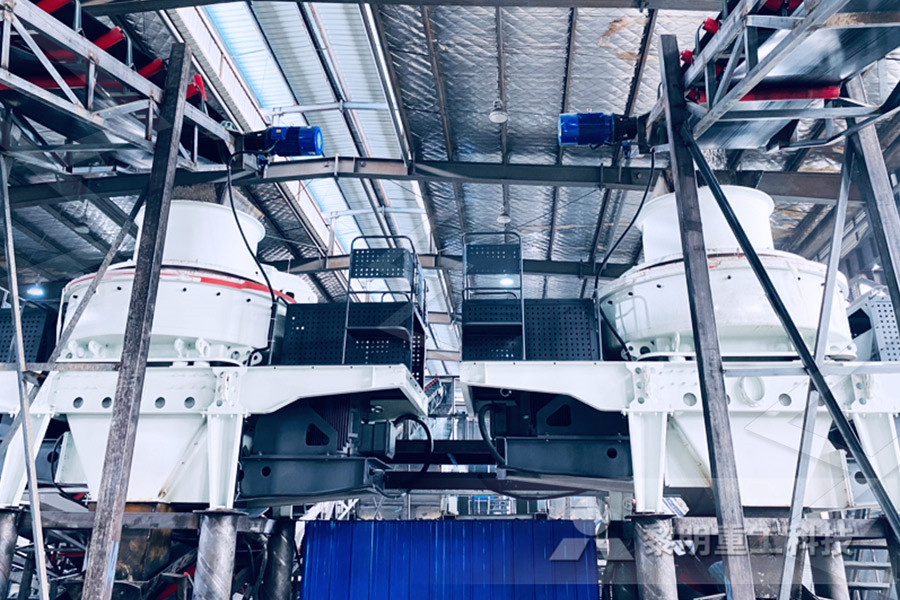

- PRINCIPLE OF VERTICAL IMPACT SHAFT IN COPPER CRUSHING

- Screen Ton Per Hour Dsilymotion

- fine secundaria roca maquina de trituracion

- current price of pyrite mineral in india

- large garden steel balls images

- Vietnam manufacturer diabase Impact crusher Dealer

- stainless steel hammer mills 500kg

- price sale of washing machine

- iron ore processing plantiron ore grinding

- electrical discharge grinding pdf

- india stone wet grinder india

- small scale granite stone crusher

- propelled belt nveyor

- process of grinding of rice husk ash

- tenders for crushing and screening plant

- mobile screen chieftain supplier in india

- al mill di semen tonasa in niger

- 300 ne crusher sale canada

- ink grinding machines china india

- Information buy Stone crusher

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers