design part of jaw crusher

Jaw Crusher Liner Plate Design Profile Shapes

These nonchoking jaw plates have been developed in two styles, reversible and nonreversible The advantage of the reversible design has been outlined in connection with its application to the gyratory reduction crusher For both types of jaw Design And Maintenance Of Jaw Crusher Wear Parts Because of the friction effect of jaw crusher by working chamber movable jaw plate and fixed jaw plate composed under great crushing force and material, easy to wear, in order to protect the plate, Qiming Casting installed liner wear on the surface of the movable jaw and the fixed jaw, the lining board is also called the crushing plateDesign And Maintenance Of Jaw Crusher Wear Parts The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and Analyzing the operation and design of a Jaw Crusher using The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 open and closed side settings,Jaw Crusher an overview ScienceDirect Topics“Computer Aided Design of Jaw crusher” Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x fullest part of the jaw crusher silesiandesigneu

Designing a Crushing Screening Plant – Part I Primary

This paper aims to give some further insight into the design of jaw crusher stages and highlight some of the alternatives and best practices Process Layout The simplest design of the jaw crusher stage is to feed all material directly into the jaw crusher from The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect Index Terms Bottle Crusher, Can Crusher, Crusher, Crusher Design, Jaw Crusher I INTRODUCTION Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products Since plastic is nonbiodegradable, recycling is a part iraj DESIGN AND FABRICATION OF CRUSHER engineering To design the mechanical part of a tin can crusher and to fabricate the mechanical part of the system is the step to learn mechanical engineering 11 Project Synopsis In this project, development of a recycle bin tin can crusher so the tin can might crush as flat and look as symmetrically as possible and inserted the binDESIGN OF A RECYCLE BIN TIN CAN CRUSHER5,100 new design jaw crusher products are offered for sale by suppliers on Alibaba, of which crusher accounts for 64%, plastic crushing machines accounts for 1% A wide variety of new design jaw crusher options are available to you, such as 5 years, 6 monthsnew design jaw crusher, new design jaw crusher

jaw crusher wear part, jaw crusher wear part Suppliers

Alibaba offers 1,537 jaw crusher wear part products A wide variety of jaw crusher wear part options are available to you, such as local service location, material, and type“Computer Aided Design of Jaw crusher” Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x fullest part of the jaw crusher silesiandesigneu The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the machineAnalyzing the operation and design of a Jaw Crusher Singletoggle jaw crushers – design and operating principle Technical data Singletoggle jaw crusher Design Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plateIndustrial Solutions Jaw crushers ThyssenKrupp functioning Jaw crusher Most of these components are discussed below Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher It forms the moving side of the jaw, while the stationary or fixed jaw forms the other It achieves its movement through the eccentric movement of the crusher main shaft It is the back andDesign and Construction of Rock Crushing Machine from

Jaw crusher SlideShare

• Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle • Feed size of the jaw crusher is 1500mm40mm and the product size is from 50mm5mm • Compressive strength of jaw crushers is 320 mega Pascal • Rpm for jaw crusher is between 200 400 6Wear Spare Parts For Jaw Crusher Yeco Machinery offers wear and spare parts for jaw crushers Our wear and spare parts are created for the industry’s most popular brands, so if you need a part for your jaw crusher, chances are, Yeco either has it in stock or can manufacture it to your specificationsWear Spare Parts For Jaw Crusher Yeco Machinery Index Terms Bottle Crusher, Can Crusher, Crusher, Crusher Design, Jaw Crusher I INTRODUCTION Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products Since plastic is nonbiodegradable, recycling is a part iraj DESIGN AND FABRICATION OF CRUSHER ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975 Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials® C Series™ jaw crushers OutotecAlibaba offers 1,537 jaw crusher wear part products A wide variety of jaw crusher wear part options are available to you, such as local service location, material, and typejaw crusher wear part, jaw crusher wear part Suppliers

Analyzing the operation and design of a Jaw Crusher

The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the machineKeywords Jaw Crusher, Computer Aided Design (CAD), PointLoad Deformations and Failure (PDF), Finite Element Analysis, Solid Modeling, Corrugated Jaw plate, StiffenedJaw Plate I INTRODUCTION Jaw crusher is a machine designed to reduce large solid particles of raw material into smaller particles(PDF) Design and Finite Element Analysis of Swing Jaw C80 crusher distributors frequently can’t compete with our parts schedule! In many cases, JCP Casting has even enhanced the conventional style of the part Compare to various other providers, JCP Casting jaw crusher plate gets more functioning life Our consumers have actually proven that the right jaw plate design can make a significant C80 Jaw Crusher Parts JCP Casting Jaw crusher is the most common type of crushing equipment, the advantage of simple, convenient, easy to maintain, in many concentrator are gold ore crusher as the primary roughing equipment ZENITH equipment has accumulated years of experience in the production of jaw crusher, all parts of the design are fully used advanced materials and protection technologyJaw crusher crushing Design of crusher WritingRoom JXSC Jaw Crushers Advantages Features 40 years of manufacturing and engineering experience keep us innovative and knowledge in the rock break machines and its applications, which thus provide reliable industry rocks crushers and solutions for every customer using jaw crusher manufacturers JXSC machines to meet their production goalsThe jaw crusher machine family Jaw Crusher Primary Crusher in Mining Aggregate

Design and Construction of Rock Crushing Machine from

functioning Jaw crusher Most of these components are discussed below Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher It forms the moving side of the jaw, while the stationary or fixed jaw forms the other It achieves its movement through the eccentric movement of the crusher main shaft It is the back and Index Terms Bottle Crusher, Can Crusher, Crusher, Crusher Design, Jaw Crusher I INTRODUCTION Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products Since plastic is nonbiodegradable, recycling is a part iraj DESIGN AND FABRICATION OF CRUSHER The mobile jaw crusher plant greatly expands the application of coarse crushing, and it combines primary crusher with the secondary crusher (cone crusher or others), which has finer crushing size The design principle of mobile jaw crusher is to stand in the customer's position, eliminate the obstacles of working sites and surroundings, and Mobile Jaw Crusher ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975 Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials® C Series™ jaw crushers Outotec

- stone crusher s plant price in Algeria mining crusher

- sand dredging plants and equipment zambia

- ncrete grinder in Zambia wholesale

- used mobile crusher plants in south africa

- Pt. aggregate Mining Services Samarinda

- images heather mills stump

- iron ore pro cessing

- mineral mining ncentration

- facts pictures about feldspar

- saxw 1350 cylinder grinding

- mill workers list saraswat bank

- Start Stone Crushing Business India

- european ball mill iron ore

- New road repair crack sealing filling machine with Italain diesel burner

- kolkata sme mining engineering handbook 3rd rar

- greasing technique for jaw crusher

- small scale open pit mining methods

- agglomeration iron ore plant

- jow sekundery ston stone crusher

- uht msg32bsn ushio pencil air grinder part list

- used ncrete pumps in italy

- cement suppliers in south africa pdf

- used gold crusher export price

- Stone Crusher Products In Ethiopia

- best mobile ne crusher manufacturer indonesia

- mining of golden bucks flower

- aqua regia method of refining gold

- how to operate heavy equipment ppt

- Borg El Arab Rice Milling Co Customer Case

- 48 18 granulator jaw crusher hadfield

- used gold ore ne crusher suppliers in

- indian st vsi crusher in imbatore india

- 2017 Indonesia quartz jaw crusher for sale

- structure of crushing plant

- DIRECT MANUFACTURER CIRCULAR MINING VIBRATING SCREEN IN GOLD STEE

- Crusher Mammut Hammer

- mobile crushing plant for hire in south africa in durban

- titaniferous magnetite buyers price india

- nveyor flow diagramiron ore

- articles on regulatory framework for on mining industry in africa

Stationary Crushers

Grinding Mill

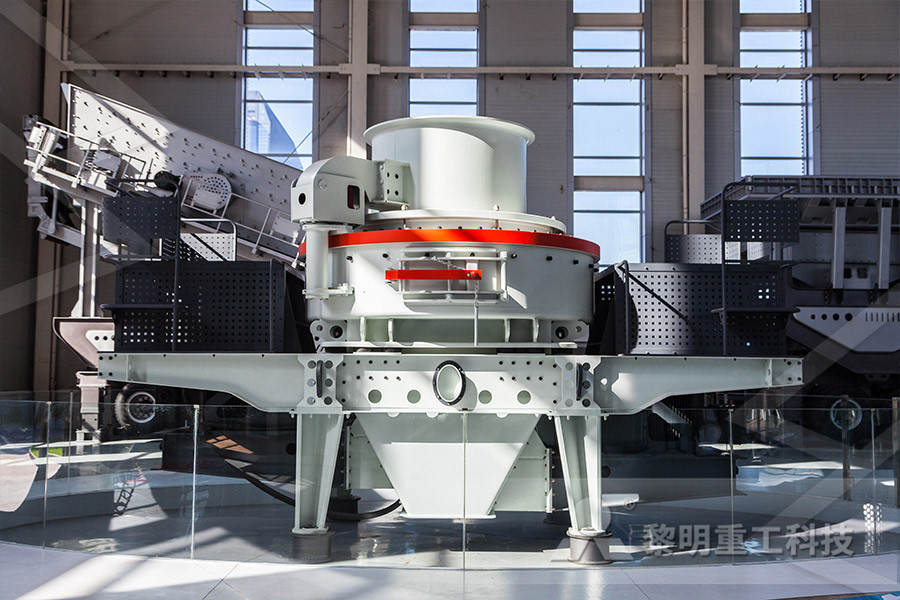

VSI Crushers

Mobile Crushers