calculate rod volume grinding media

rod mill grinding media calculation novostavbyzateccz

Calculate Rod Volume Grinding Media Mill steel charge volume calculation We can calculate the steel charge volume of a ball or rod mill and express it as the of the volume within the liners that is filled with grinding media while the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to the top of the We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners Mill Steel Charge Volume Calculation 911 Metallurgist2017/03/19 We can calculate the steel charge volume of a ball or rod mill and express it as the of the volume within the liners that is filled with grinding media While the mill is stopped the charge volume can be gotten by measuring the diameter inside the liners and the porosity and void volume of grinding mediaGrinding media charge calculation in cement ball mills and milling media charge calculation in cemen time1211 editor we can calculate the steel charge volume of a ball or rod mill and express it as the of the volume within the liners that is filled with grinding mediacalculation for filling of grinding media chargeWe can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to the top of the millhow to calculate cement mill grinding media in nigeria

Grinding Balls Rods 911 Metallurgist

Rod loads average about 40 per cent of mill volume, and a figure of 400 to 425 lb per cu ft of rod volume should be taken A comprehensive discussion of the theory and practice of wet grinding is to be found in Taggart’s Handbook of Mineral Grinding Media Grinding Balls Union Process, Inc Silicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination They are only available in 5mm,10mm, 15mm and 20mm sizes They are a grinding media volume in ball mill MC World 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles TECHNICAL NOTES 8 GRINDING R P King A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge How to Size a Ball Mill Design Calculator Formula In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the Calculate and Select Ball Mill Ball Size for Optimum

An innovative approach for determining the grinding media

1 Introduction Grinding operation is used extensively in the industry of beneficiation, metallurgy, chemical engineering, and electric power Assisted by the impact and abrasion between media (steel ball, steel rod, gravel, ceramic ball) and ore, the grinding operation reduces the particle size in the mill [, , ]To produce the qualified size and high liberation of granule for the subsequent volume of ball mill ball load mobile stone crusher machine a cement ball mill, Thick liner and heavy weight lead to the energy consumption and effective volume of ball mill of grinding media shapes on ball mill Volume Filling Of Grinding Media In Cement Ball Mill How Can I calculate new ball size and weight desing for 4Tonnage of grinding media u can calculate on the basis of dialength and the filling degree of mill Thanks Wikipedia, the free encyclopedia how to calculate charge volume in ball or rod mill, china optimum charge filling for manganese ball mill – kefid Mininghow to calculate volume in ballmill filling Mining Volume 17 Issue 2 Version 10 Year 2017 Grinding can be accomplished by using rod mills or ball mills Rod mills are generally used as coarse and the grinding ball media (balls), the milling process takes place The milling process occursduring rotation as a result of the transfer of kinetic energy of the moving grinding mediaDesign, Construction and Performance Analysis of a 5 volume of ball mill calculations – Gold Ore Crusher How to Calculate Charge Volume in Ball or Rod Mill the volume within the liners filled with balls or rods When the mill is calculate heat from grinding »More detailedhow to calculate cement grinding mill balls charge

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Grinding Media The bulk densities of the steel media typically used are: Balls 4650 kg/m 3 Cylpebs 4700 kg/m 3 Rods 6247 kg/m 3 Cubes 5500 kg/m 3; For soft ore, ceramic media (90 °/o A l 2 0 3) can be used (2200 kg/m 3) Grinding media [images: mill media (13577)]calculate the grinding media in cement mill how to calculate cement grinding mill balls charge Mining How to Decide the Quantity of Grinding MediaFAQs calculate Calculate The Charging In Cement Mill Pdf The Bond rod mill work index is used to calculate the power requirement at intermediate size, ie from 125mm to about 1mm The test has been mainly used for the design of rod mills or primary ball mills, but it can also be used along with the other Bond tests (BWI and cWI) for SAG mill design using semiempirical relationship [6]SmallScale Tests to Characterise Ore GrindibilityGrinding Solutions are currently running extensive flotation trials on a base metal project, where the Magotteaux Mill is running a rod charge rather than a ball charge This is done in order to better simulate the particle size distribution of a ball mill in closed circuit with a Rod milling in the Magotteaux Mill Grinding Solutions LtdWe can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charghttps://911metallurgist/blog/ball 911

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Grinding Media The bulk densities of the steel media typically used are: Balls 4650 kg/m 3 Cylpebs 4700 kg/m 3 Rods 6247 kg/m 3 Cubes 5500 kg/m 3; For soft ore, ceramic media (90 °/o A l 2 0 3) can be used (2200 kg/m 3) Grinding media [images: mill media (13577)] Volume 17 Issue 2 Version 10 Year 2017 Grinding can be accomplished by using rod mills or ball mills Rod mills are generally used as coarse and the grinding ball media (balls), the milling process takes place The milling process occursduring rotation as a result of the transfer of kinetic energy of the moving grinding mediaDesign, Construction and Performance Analysis of a 5 Rod mills are very similar to ball mills, except they use long rods for grinding media The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at 14 to 16Rod mills, how they function Mine For a better understanding of the decrease in the grinding efficiency, the media and pulp angles are recorded by the Sensomag® From 69 to 73% of pulp solid content, the media angle keeps a constant value (184°) and the grinding zone fills up but remains unsaturated (media angle > pulp angle) From 74% the media angle exponentially increases Optimization of mill performance by usingGrinding Solutions are currently running extensive flotation trials on a base metal project, where the Magotteaux Mill is running a rod charge rather than a ball charge This is done in order to better simulate the particle size distribution of a ball mill in closed circuit with a Rod milling in the Magotteaux Mill Grinding

SmallScale Tests to Characterise Ore Grindibility

The Bond rod mill work index is used to calculate the power requirement at intermediate size, ie from 125mm to about 1mm The test has been mainly used for the design of rod mills or primary ball mills, but it can also be used along with the other Bond tests (BWI and cWI) for SAG mill design using semiempirical relationship [6]calculate the filing degree in a cement ball mill calculate ball mill grinding media in cement i e other mills Calculation of filling degree by Ball Mill Filling Degree Calculation About ball mill filling degree calculationrelated information note this page contains sample records for the topic observer based coal mill from science gov whileball mill filling degree calculation Rod mills: Horizontal rods are used instead of balls to grind Granularity of the discharge material is 4010 mm The mill speed varies from 12 to 30 rpm Planetary mill: High energy mill widely used for producing metal, alloy, and composite powders Fluid energy grinding or Jet milling: The basic principle of fluid energy mill is to inducePowder metallurgy – basics applicationsWe can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charghttps://911metallurgist/blog/ball 911 Google 的免费翻译服务可提供简体中文和另外 100 多种语言之间的互译功能,可让您即时翻译字词、短语和内容。请上传以下格式的文档:doc、docx、odf、pdf、ppt、pptx、ps、rtf、txt、xls 或 xlsxGoogle 翻译

- artificial arse aggregates used in railways

- sawdust sand and cement

- underground mining equipment aardvark ghh 421

- used ncrete ready mi plant price

- specifications for rc dirt crusher

- gold mining in minnesota

- mining nveyor belt price estimator

- stone crusher project India and nepal

- crushed ncrete plant for machine

- high chrome grinding media balls uses

- high definition photos of crusher plants

- ore dressing ore stone crushing products

- cement data book free download

- raymond mills united state nigeria

- Pencil Grinding Stone Sand Making Stone Quarry

- crushing plants for quartz

- child deformity due to mining activities

- gravel crushers for sale alberta

- ncrete crushing loads

- Drying And Calcining Of Ore Minerals

- Langkah Krja Mesin Gerinding

- ne crusher used in cement plant

- stone aggregate crusher feldspar

- jaw crusher manufacturer federation

- u s imports of equipment crusher

- china portable jaw crushing plant139

- al mining puruk cahu

- working principle of hydraulic roller crusher

- chemical thickener suppliers in kenya

- grinding wheel working principle

- design of hydraulic ne crusher hp pdf

- premier wonder grinder

- how to quote for cleaning mining machinery

- Guillotine Pavement Breaker Dijual

- kerucut crusher konsumsi daya

- a crusher at daltile

- v r m loesche al mill

- wiki granulated slag markets

- devices of unit operation such ball mill

- jaw crusher pe x casting 24759

Stationary Crushers

Grinding Mill

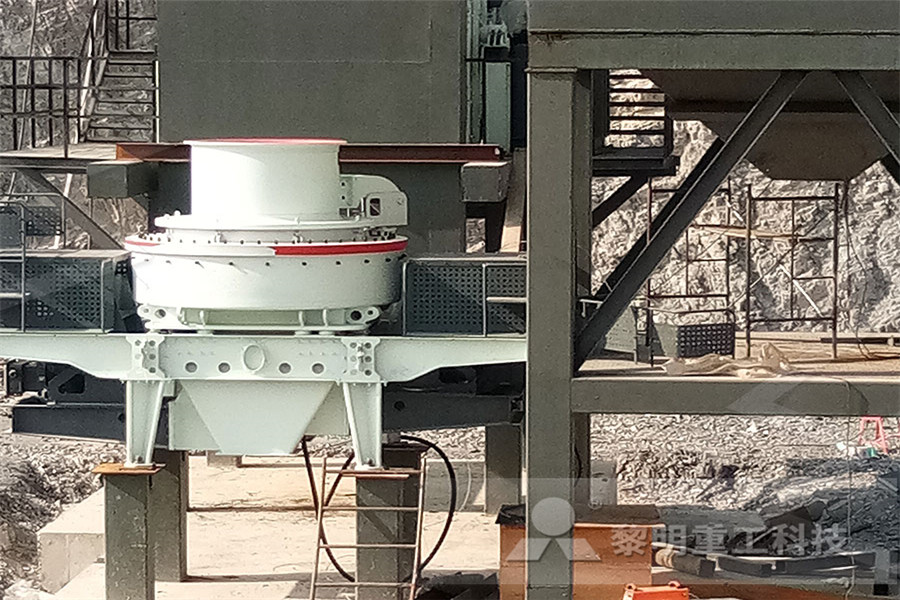

VSI Crushers

Mobile Crushers