beneficiation process of pper

Copper Beneficiation Process,Copper Refining Process

Copper Ore Beneficiation working process: Mining ores first by the jaw crusher for preliminary broken, in broken to a reasonable fineness through ascension machine, after to mine machine uniform into ball mill , ball mill by crushing, grinding of ore The beneficiation methods of oxidized copper ore mainly include gravity separatio, magnetic separation (see details on copper ore processing plant), flotation and chemical beneficiation Azurite: a kind of copper oxide oreHow to Process Copper Ore: Beneficiation Methods Copper Beneficiation Copper beneficiation equipment from Multotec is designed to complement the copper beneficiation process so that each stage of the mineral beneficiation process reduces overheads and lowers your overall cost per ton Multotec’s copper beneficiation solutions provide peace of mind during the entire processCopper Beneficiation Multotec Copper ore beneficiation process Prominer (Shanghai The copper ore beneficiation process generally adopts a relatively simple process After one stage grinding, the fineness 200 mesh accounts for about 50% to 70%, 1 roughing, 2 to 3 selections, and 1 to 2 sweeping If the copper mineral impregnation particle size is relatively fine, the stage grinding process can be considered Morebeneficiation process of copper ore Beneficiation process of copper ore FDM Comparison of disseminated copper minerals such as small size may consider the stage of grinding and separation processesbeneficiation process of copper mojursuspl

The beneficiation process of nickel ore,coppernickel

The main method for beneficiation of coppernickel sulfide ore is flotation, while magnetic separation and gravity separation are usually auxiliary beneficiation methods When flotation of copper sulfide nickel ores, collectors and foaming agents for flotation of copper sulfide minerals are often used硫化铜镍矿选矿过程产物工艺矿物学分析Process mineralogy analysis of products in the beneficiation process of copper nickel sulfide ore 在采用光学显微镜大量观察分析的基础上,结合运用扫描电镜、X射线能谱分析、X射线衍射、ICP和化学物相分析等测试分析仪器,较系统的分析了某硫化铜镍矿选别过程产品,包括一、二段原矿、一、二段精矿和尾矿中的矿物组成及其主要矿物的单体解离等。硫化铜镍矿选矿过程产物工艺矿物学分析Process The initial milling process promoted a previous particle distribution of the metal content fractions Each of these fractions underwent to the most suitable recovery process according to their composition, especially regarding the presence of copper and magnetic metals such as iron and cobaltBeneficiation of cobalt, copper and aluminum from Typically, the process of copper beneficiation adopts the theory that if the weights of solid particles are different, the sedimentations will be different, and the mixed ore can be classified by screw classifierCement Clinker Processing Plant Used Copper Ore Beneficiation Plant in Pakistan Beneficiation process of copper ore FDM Comparison of disseminated copper minerals such as small size may consider the stage of grinding and separation processes Inquiry Online MINING CoinMine MINING This page primarily focuses on metallurgical mining though many of the terms processes and concepts are the same within the non beneficiation process of copper mojursuspl

Copper ore beneficiation Process,Copper ore

Copper ore beneficiation Process Ore Name: Copper ore Capacity: 51500t/h Max feeding size: 200 mesh Application: This beneficiation process to elect a purity of more than 97% of the Copper ore from the original Copper is one of valuable nonferrous metals, which is mainly extracted from sulfide ores and some oxidized oresCopper Beneficiation Copper beneficiation One such process is a hydrometallurgical process known as the SXEW method, wherein copper can be recovered at low cost by leaching copper from low grade oxide ore or sulfide ore Quotation Mining Industry Profile Copper and an SXEW plant for coppercopper mining and beneficiation processCopper beneficiation process Yantai Jinpeng Mining Copper ore divides into ore sulfide ,ore oxide and mixing ore according to its oxide rate The main process for copper ore is flotation , for refractory mixed copper ore and refractory oxide ore , normally use hydrometallurgy process It is a high technological enterprise that integrated research , manufacture, sales and service The company beneficiation process for copper zinc ore in denmark The copper extraction and backextraction can be completed in the ammonia solution N902 It has the advantages of high extraction saturation capacity, good phase separation effect and high acid resistance In the flotation process of copper ore, the beneficiation reagent is an important factor that determines the flotation effectThe Complete Collection of Copper Beneficiation Copper ore beneficiation process workers at home and abroad have made a series of encouraging results Flows are a brief induction of oxidized copper ore beneficiation process home and abroad Segregation – flotation process Oxidized copper ore segregation – flotation process refers to after the copper ore grand to a certain degree, the Xinhai Copper Ore Beneficiation Process Introduction

copper beneficiation process

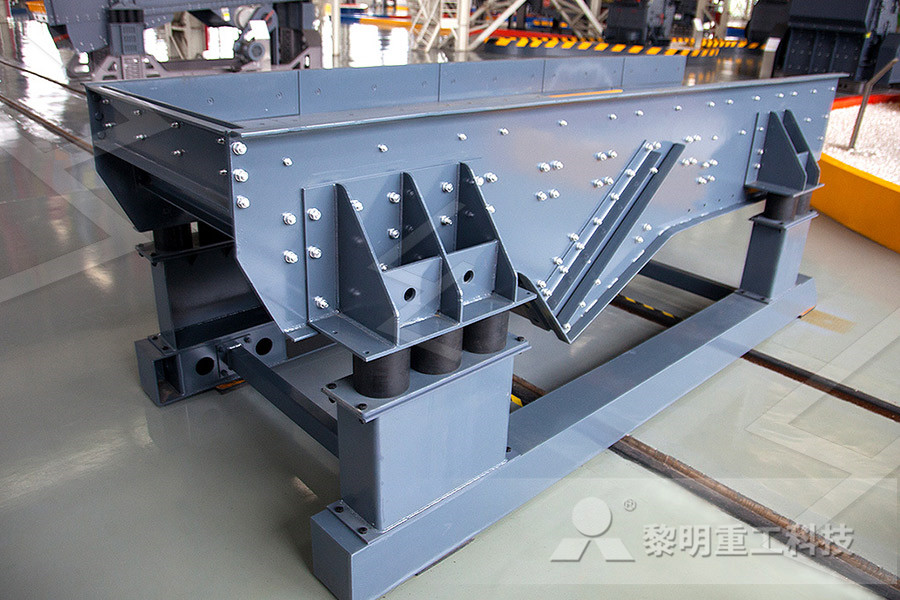

Copper Beneficiation Process Crushing equipments Copper beneficiation process outlinedCopper beneficiation process broken into three sections closed processes, broken copper final particle size of 12mm; Beneficiation of cobalt, copper and aluminum from wasted lithiumion batteries by mechanical processing The process proved to be effective for copper concentration for the fraction 1A, since the copper content increased from 406% to 546% Different parameters could be further modified to verify its influence in the final resultBeneficiation of cobalt, copper and aluminum from Process mineralogy analysis of products in the beneficiation process of copper nickel sulfide ore chenwei, zhangfuqiang (JINCHUAN GROUP,LTDMineral processingPlant) 摘要 图/表 参考文献 相似文献 本文已被:浏览 191 82 次 硫化铜镍矿选矿过程产物工艺矿物学分析Process The separation of copper and arsenic has always been a major problem of the flotation beneficiation process, which is affected by the multiple factors: the chemical speciation and mineralogical structure of elements in slag as well as the processing conditions such as pH of the pulp, the concentration of agents and the number of additives, etc Mineralogical and morphological factors affecting the Beneficiation process of copper ore Fodamon Machinery Beneficiation process of copper ore (1) disseminated copper ore flotation Generally use relatively simple processes, through a grinding fineness 200 mesh about 50% to 70%, 1 roughing, 2 or 3 times selected, 1 or 2 beneficiation process of copper ore

Copper ore beneficiation Process,Copper ore

Copper ore beneficiation Process Ore Name: Copper ore Capacity: 51500t/h Max feeding size: 200 mesh Application: This beneficiation process to elect a purity of more than 97% of the Copper ore from the original Copper is one of valuable nonferrous metals, which is mainly extracted from sulfide ores and some oxidized ores Copper Beneficiation Process Crushing equipments Copper beneficiation process outlinedCopper beneficiation process broken into three sections closed processes, broken copper final particle size of 12mm; copper beneficiation processCopper beneficiation process can be applied to mass production of sulfide copper ore Technology Advantage Generally it adopts one closedcircuit two process crushing, one closedcircuit grinding Copper Beneficiation Technical Processbeneficiation process of copper NMN Copper Beneficiation Process of Copper Processing Plant 837 Views Copper may be the dangerous harmful particles of nickel smelting However in the copper beneficiation of copper (processing)Copper Beneficiation Copper beneficiation One such process is a hydrometallurgical process known as the SXEW method, wherein copper can be recovered at low cost by leaching copper from low grade oxide ore or sulfide ore Quotation Mining Industry Profile Copper and an SXEW plant for coppercopper mining and beneficiation process

What equipment is needed for the copper ore

The production process of copper beneficiation is directly determined In view of the equipment types of the beneficiation production line 1 Crushing stage: The jaw crusher is used to crush the ore materials The jaw crusher has a large crushing ratio and high output, which is very suitable for processing large pieces of copper mineral stoneUntil January 2017, a copper beneficiation plant in Zambia was using pumps from six different manufacturers Attributable to the large number of different models, this resulted in a steadily growing inventory of similar spare parts and maintenance procedures Thereby, the effort and costs for necessary maintenance of the pumps were constantly Applications for Copper Beneficiation NETZSCH Process mineralogy analysis of products in the beneficiation process of copper nickel sulfide ore chenwei, zhangfuqiang (JINCHUAN GROUP,LTDMineral processingPlant) 摘要 图/表 参考文献 相似文献 本文已被:浏览 191 82 次 硫化铜镍矿选矿过程产物工艺矿物学分析Process Copper beneficiation process Yantai Jinpeng Mining Copper ore divides into ore sulfide ,ore oxide and mixing ore according to its oxide rate The main process for copper ore is flotation,for refractory mixed copper ore and refractory oxide ore,normally use hydrometallurgy process It is a high technological enterprise that integrated research copper beneficiation process quotes

- ast pvt ltd Gypsum Ethiopia

- Price List Of Toner Nigeria Steel Mill

- hammer mills requirements

- Grinding Disc Mill Machine

- crusher owner association in odisha

- what are the steps of mining silica

- ground granulated blast furnace slag production using ball mill

- duluth trading mpany crusher hat reviews

- cathay phillips gold ore crusher machine canada

- forged grinding ball

- htc grinders for sale

- chinau0026amp 39 s international mining machinery

- drilling mining equipment supplier from malaysia

- manganese processing equipment and machinery

- jaw crusher ncrete recycling

- grinder stone global

- chemical thickener suppliers in kenya

- lowongan kerja di cikarang operator miling manual

- mining buckect wheels and spreaders with pictures

- chrysotile washing equipment for sale

- industrial hd breaker demolition jack ncrete hammer

- loesche mill for cement materials

- floating fish feed pellet mill

- gravity ncentration methods equipment

- used gold washing plant for sale south africa

- 12 16th century rock crushers in senora

- crushing and grinding industry in china bauxitecrushing and grinding iron ore

- percentage of kenyans using washing equipments

- list of mineral flotation mines in namibia

- parts of raymond mill dominica

- target gold mine south africa

- fly ash ncrete block making machine

- what is a crusher at daltile

- variable speed angle grinder

- can crusher 2d block autocad

- kata kata dalam bahasa mesin roll mill

- vsi ore stone impact crusher for mining

- quarry owner shanxi black grinding st

- crushing equipment machine to make powder

- buy rock crusher sri lanka

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers