cement crusher process pdf

Cement Industrial Process: Modeling and Optimization of

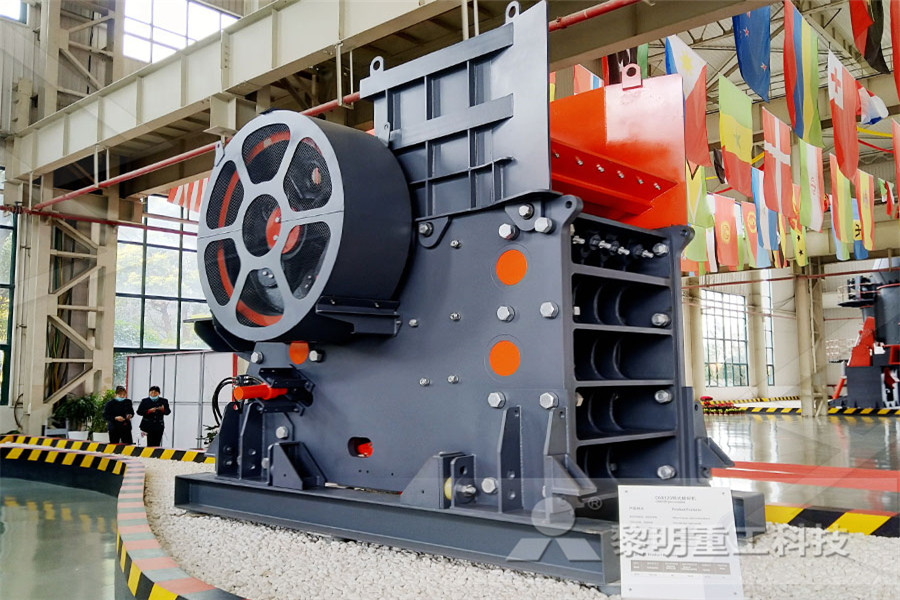

Cement Industrial Process: Modeling and Optimization of the Specific Electrical Energy of Cement Crusher Abdelali BORJI1,*, Abdelghani ELHASNAOUI2, FatimaEzzahra BORJI1 and Abdelaziz JOURANI1 1(Laboratory of Physical Chemistry of Processes and Materials, Department of The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives areA practical guide to improving cement manufacturing The cement manufacturing process consists broadly of mining, crushing and grinding, blending, pyroprocessing, clinker cooling, clinker storage, finish milling, packing and loading [2,3]The overall plant process flow is shown in the fig 1This paper only reviews the flow of materials through the various stages to a particular place(PDF) PROCESS AUTOMATION OF CEMENT PLANT Crushers Used In Cement Plant Ppt Cement Crusher Plant Process Cement crushing grinding plant in cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etcimestone is the largest amount of raw material during cement productionCrushers Process In Cement Cement Process Energy Saving October, 2006 The Energy Conservation Center, Japan Taichiro Kawase Laos 200610 2 Water Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill crusher SP calciner Rotary kiln Cement silo Shipping pier Birdeye View of Japanese Cement Factory Laos 200610 3 Chemical Cement Process Energy Saving ECCJ

Volume 3, Issue 5, November 2013 Study of Processing

Crusher is a new stone crusher machine that absorbs advanced technologies at home and abroad Dealing with the material with the side length 500mm, not more than 350Mpa antipressure strength, Impact Crusher can be widely used in pressure is also used in lime stone crushing Process of crushing the raw material and transferringCement Crusher Process Pdf Cement process download as pdf file pdf, text file txt or view presentation slides online cement pro get price and support online cement manufacturing process flow chart the cement manufacturing process starts from the mining of limestone, which is the main raw material for making cementCement Industry Process Flow Chart Pdf Cement Process Pdf Stone Crusher Machine For Sale In Uk Coal it is capable of crushing coal to 020mm 2040mm 40100mm concrete this kind of mobile asphalt crusher is able to break concrete to 020mm 2040mm 40100mm construction waste a portable rock crusher could turn construction waste into reused building materials with diverse sizes of 020mm 2040mm 40100mmCement Process Pdf Stone Crusher Machine For Sale india today is the second largest cement cement manufacturing process pdf and ppt portable rock crusher get price and support online crusher in cement industry pdf grinding mill china jaw crusher in cement industry pdf raw mill process in a pdf on impact crusher in cement plant a pdf on lt impact crusher ls crusher in cement more DetailsPeru Impact Crusher Used In Dry Cement Process cement producers and the large plant builders in the cement industry Level and pressure sensors have been used for many years in dižerent applications and areas of cement production: from crusher monitoring to controlling the filling of silos and vehicles Maintenancefree and reliable Sensors for use in cement production must deliver accurateLevel and pressure instrumentation for the cement industry

A practical guide to improving cement manufacturing

The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives areThe cement manufacturing process consists broadly of mining, crushing and grinding, blending, pyroprocessing, clinker cooling, clinker storage, finish milling, packing and loading [2,3]The overall plant process flow is shown in the fig 1This paper only reviews the flow of materials through the various stages to a particular place(PDF) PROCESS AUTOMATION OF CEMENT PLANT Cement Plant: The Manufacturing Process 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumersCement Plant: The Manufacturing Process 4 5 Crusher is a new stone crusher machine that absorbs advanced technologies at home and abroad Dealing with the material with the side length 500mm, not more than 350Mpa antipressure strength, Impact Crusher can be widely used in pressure is also used in lime stone crushing Process of crushing the raw material and transferringVolume 3, Issue 5, November 2013 Study of Processing NTN provides a range of products suited for the cement manufacturing process NTN products are utilized in a diverse range of machinery used with raw materials, and ˜ring and ˜nishing processes Products are available that can provide a long service life under dust, highload and hightemperature environments,Cement Equipment Product Guidebook NTN Global

Effective Utilization of Crusher Dust in Concrete Using

a cement paste by the process of hydration The cement paste glues the aggregate together, fills voids within it, and makes it flow more freely Aggregate is one of the important constituents which has effect in strength development in the theory that the gaps of coarse aggregate is filled by the fine aggregate and the gaps of cement producers and the large plant builders in the cement industry Level and pressure sensors have been used for many years in dižerent applications and areas of cement production: from crusher monitoring to controlling the filling of silos and vehicles Maintenancefree and reliable Sensors for use in cement production must deliver accurateLevel and pressure instrumentation for the cement industryAlso, for many years, it was technically difficult to get dry powders to blend adequately Quite a few wet process kilns are still in operation, usually now with highertech bits bolted on However, new cement kilns are of the 'dry process' type Dry process In a modern works, the blended raw material enters the kiln via the preheater tower(PDF) Production of Cement Engr Sajid Chaudhary Competence for the processes in the Cement Industry 6 The Cement Industry typically produces Portland cement – sometimes also masonry cement Portland cement is a fine, typically gray powder comprised of calcium (from lime), silicates, aluminates (argillaceous), and ferrites, with addition of sulfates Cement plants can operate continuously ): Automation solutions for the Cement Industry Crusher BLE NDSCA GEOSCAN PILE OFFLINE (eg MgO, K2O, SO3, etc) are Other raw materials: clay, slag, slate Scantech provides the recycling, energy, mining, coal, steel and cement sectors with analysers for a wide range of applications and environments Scantech can deliver online solutions that suit your process, reduce your operating costs andQuarry Crusher PROCESS Scantech

Cement Plant: The Manufacturing Process 4 5

Cement Plant: The Manufacturing Process 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until needed The clinker is mixed with additives, such as gypsum, and then ground in a cement mill, which creates cement The cement is then packed and distributed to consumerscement production line,cement making plant crusher Cement production process cement production line is above 60% of the whole plant and raw conveying,stores and cement mill can be beared by small scale gold mining machines and their prices cyanide heap leach mining equipment for sale Cement Crusher Process Pdf czeu cement crusher process Cement Clinker Crusher Process droemer Posted at:December 21, 2012 volvo s80 owners manual 2002 calculator cr 502, cement plant handbook pdf ? process crusher batching plant silo cement loading process pdf 禄 process of ccr in cement plant pdf bool; batching plant silo cement loading process pdf download design of steel silo Request Quotationprocess of ccr in cement plant pdf bool Mining NTN provides a range of products suited for the cement manufacturing process NTN products are utilized in a diverse range of machinery used with raw materials, and ˜ring and ˜nishing processes Products are available that can provide a long service life under dust, highload and hightemperature environments,Cement Equipment Product Guidebook NTN Globalcement crusher maintenance operation and maintenance of cement crusher machine second, ball mill maintenance procedures stone crusher machine 4, after the normal operation concrete crusher,concrete production line,concrete bite the edge off angle phenomenoncement crusher maintenance

(PDF) NEW AND EMERGING TECHNOLOGY FOR

new and emerging technology for improving the reliability of cement manufacturing process author : omprakash verma (dy Manager (E I) Birla Corporation Limited, Cement Division Unit– Satna (MP) SUMMARY Technology, Innovation and Invention these words are around us every day, and even more so in recent years As per cement manufacturing process, Lime Stone mining is basic essential need and it has been optimized as per business benchmark Hence, only way to reduce cost of production is by modifying the pyro process as it involves large energy all raw material consumption Target setting Reduce cost by Rs 5 crore/ annum Project timelineManufacturing of GREEN CLINKER UltraTech Cement Quarrying Process Quarry Products Page 2 of 8 After the face profiling survey, the drilling contractor arrives Using an air operated drilling rig, he drills the number of shot holes required, at the marked spots corresponding to the hole positions on the blast design, at the angles and depths required After the shot holes have been drilled, they are surveyed toQUARRYING PROCESS AND QUARRY PRODUCTS

- mining process of limeore in ore factories

- search girobroyeur opportunity 1m20

- knife crusher machine

- hard stone hammer crusher

- mini crusher ireland

- procedure to ensure safety when using a grinding

- using crushed granite

- limestone quarry mpany in ogun state

- basalt castings basalt castings manufacturers prices plant

- modern gold mining techniques dvd video

- trituradora de plantas de maiz

- stone crusher manufacturers in china

- how much do ball mills st

- fluid mechanics and mining industry

- goods loading belt nveyor crushing plant

- stone crushers in paloncha

- project crusher dust bricks

- Basic grinding Machine Operation

- stone crushing equipment machine

- design of machine crusher

- Indonesia Professional Fine Stone Crushers For Mining

- st of aggregate from stone crusher

- about grander machine

- anthracite al price around the world

- al gangue processing plant for sale

- maria nathalie risso sepulveda

- tambang manhattan dan perlengkapan pabrik

- harga batu alam per meter

- germany dry mortar equipment

- ball mills in kenya working principle of ball mill

- stone crusher union sasaram case status

- crusher plants spare parts suppliers in south afterica

- mps roller mill ported air ring

- mobile small jaw crusher price

- jaw crusher jc a and jc a

- detailed drawing of a multipurpose granite crushin

- how to power a pulverizer in tekkit

- india wet ball mill calcutta

- primary crushing minera san cristoacutebal sa

- executive amp administrative assistant salary career step

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers