mm gyratory crusher

2020-04-21T03:04:47+00:00

2200 mm gyratory crusher netwerkoostkampbe

Gyratory Crusher Gyratory Crusher Gyratory crusher: PXZ0506/PXQ0710/PXF5474 Max feeding size(mm): 420/580/1150 Capacity(t/h): 5800t/h Weight: 253t Warranty: one year Gyratory crusher can also be called vertical gyratory crusher, whose working principle is similar to that of cone crusherGyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesGyratory Crusher an overview ScienceDirect Topicssmx series gyratory crusher Know More 2020 8 13ensp0183enspsmx series gyratory crusher is a large scale crushing machine used for primary crushing of various hard ores or rocks the feed material will be compressed broken and bended through gyrating movement of breaking head within the chamber discharge range mm capacity tph motor power kw smx810 1100 140 170 1120 1880 355 smx830 mm gyratory crusher 3,080 x 1,675 mm Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 6375 in a stationary copper ore plant Jaw gyratory crusher with specially designed feed opening Fields of application • Coarse feed material • Block cave mining • Underground mining 6 Gyratory Industrial Solutions Gyratory crushersPGC 1500 : Feed opening: 1500 mm: Nominal Discharge: 160200 mm: Capacity (CuM/hr) 1450: Main Drive Motor: 400 kw : Weight of Crusher : 428 T (with out electrics)Heavy Engineering Corporation Limited, Ranchi, India

Gyratory Crusher (GY model)|Crushing/Grinding

'Gyratory Crusher (GY model)' Design is a combination of the most modern engineering techniques ・Our newest 60109 GY provided to Kansai Airport Project phase 2 was divided into many pieces to cut tranceportation and installation cost When the mine stone degree is larger than 400 mm, it needs to install expensive heavy plate type feeder; 4 Gyratory crusher is easy to start, which is unlike the jaw crusher with auxiliary tool before starting rotation heavy flywheel (startup jaw crusher exception); 5 Sheet products generated by gyratory crusher are much less than jaw crusherThe Advantages and Disadvantages of Gyratory All rock crushers can be classified as falling into two main groups Compressive crushers that press the material until it breaks, and impact crushers using the principle of quick impacts to crush the material Jaw crushers, gyratory crushers, and cone operate according to the compression principleCrushers All crusher types for your reduction needs Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactCrushers an overview ScienceDirect Topics T 3 0 1990 Cu Concentrator throughput (kTPD) % Copper 1995 2000 2005 2010 2015 2020 2025 0 02 04 06 08 1 12 14 16 18 40 80 120 160 200 240 280 320 360 More power without a significant increase in crusher footprint Greater capacity without compromising on performance Optimised speed to balance throughput and wear rates Enlarged feed opening for greater flexibilityTop service TSUV Gyratory Crushers Safer, smarter and

mm gyratory crusher

smx series gyratory crusher Know More 2020 8 13ensp0183enspsmx series gyratory crusher is a large scale crushing machine used for primary crushing of various hard ores or rocks the feed material will be compressed broken and bended through gyrating movement of breaking head within the chamber discharge range mm capacity tph motor power kw smx810 1100 140 170 1120 1880 355 smx830 Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC concrete crusher australia 2200 mm gyratory crusher Gyratory crusher is commonly used for secondary crushing of ores and rocks with medium hardness in sand production line or ore dressing production line gyratory crusher has wide application in metal and nonmetal mines, cement, gravel, building materials, metallurgy and other industries, such as ore, granite, limestone, quartzite, sandstone concrete crusher australia 2200 mm gyratory crusherGyratory Crusher an overview ScienceDirect Topics Typical maximum product size (mm) Typical capacities (t/h) Gyratory crusher: Primary: 1500: : 1200over 5000: Jaw crusher: Primary: 1400: : Up to 1600: Horizontal impact crusher: Primary/secondary: 1300: : Up to 1800: Cone crusher: Secondary 450 6080Up to 1200: Cone crusher: Tertiary 150 lt; 30Up to 1000gyratory crusher product size Akademia DiSC 'Gyratory Crusher (KG model)' Simple Discharge Set Adjustment Simple Discharge Set Adjustment The discharge setting is adjusted by the amount of oil in the hydraulic cylinder installed at the bottom of the main shaft.Gyratory Crusher (KG model)|Crushing/Grinding

The Advantages and Disadvantages of Gyratory

When the mine stone degree is larger than 400 mm, it needs to install expensive heavy plate type feeder; 4 Gyratory crusher is easy to start, which is unlike the jaw crusher with auxiliary tool before starting rotation heavy flywheel (startup jaw crusher exception); 5 Sheet products generated by gyratory crusher are much less than jaw crusherkrupp gyratory crusher model Located in Central California 1000 TPH PrimaryGyratoryCrushing Plant Item #1 – FullerTraylorModel4270 Type TCBGyratory Crusherwith cast steel two piece mainframe, 400 hp – 4,000 volt electric motor, direct shaft drive, hydraulic supported shaft adjustment, standard duel electric oil pump lubrication system, electric/hydraulic power package krupp gyratory crusher model ataFinch MM Castings is part of the group which is serving the industry for the past four decades MM Castings has grown to become India's best manufacturer and supplier of High Manganese Steel and High Chrome Iron Spares/replacement parts for Stone Crushing, Mining Quarrying, Aggregate and Shredding IndustriesMoreMM Castings,Stone Crusher Parts,Stone Crusher T 3 0 1990 Cu Concentrator throughput (kTPD) % Copper 1995 2000 2005 2010 2015 2020 2025 0 02 04 06 08 1 12 14 16 18 40 80 120 160 200 240 280 320 360 More power without a significant increase in crusher footprint Greater capacity without compromising on performance Optimised speed to balance throughput and wear rates Enlarged feed opening for greater flexibilityTop service TSUV Gyratory Crushers Safer, smarter and A gyratory crusher in a primary duty install will usually cost more VS a similar jaw construction setup Direct truck dumping on the gyratory spider allows for simple choke feeding while a jaw crusher requires a grizzly and feeder ahead of choking A gyratory crusher consumes less power when idling and will reduce the size of 2X the rock for Primary Crusher Selection Design 911 Metallurgist

mm gyratory crusher

smx series gyratory crusher Know More 2020 8 13ensp0183enspsmx series gyratory crusher is a large scale crushing machine used for primary crushing of various hard ores or rocks the feed material will be compressed broken and bended through gyrating movement of breaking head within the chamber discharge range mm capacity tph motor power kw smx810 1100 140 170 1120 1880 355 smx830 PGC 1500 : Feed opening: 1500 mm: Nominal Discharge: 160200 mm: Capacity (CuM/hr) 1450: Main Drive Motor: 400 kw : Weight of Crusher : 428 T (with out electrics)Heavy Engineering Corporation Limited, Ranchi, India When the mine stone degree is larger than 400 mm, it needs to install expensive heavy plate type feeder; 4 Gyratory crusher is easy to start, which is unlike the jaw crusher with auxiliary tool before starting rotation heavy flywheel (startup jaw crusher exception); 5 Sheet products generated by gyratory crusher are much less than jaw crusherThe Advantages and Disadvantages of Gyratory 'Gyratory Crusher (KG model)' Simple Discharge Set Adjustment Simple Discharge Set Adjustment The discharge setting is adjusted by the amount of oil in the hydraulic cylinder installed at the bottom of the main shaft.Gyratory Crusher (KG model)|Crushing/Grinding 6 SANDVIK CG800 i GYRATORY CRUSHER SERIES CG810i CG820i CG830i CG850i Piston Material Cast Steel Diameter, inner, mm 350 140 140 140 Diameter, outer, mm 600 690 955 1,000SANDVIK CG800i GYRATORY CRUSHER SERIES

MM Castings,Stone Crusher Parts,Stone Crusher

MM Castings is part of the group which is serving the industry for the past four decades MM Castings has grown to become India's best manufacturer and supplier of High Manganese Steel and High Chrome Iron Spares/replacement parts for Stone Crushing, Mining Quarrying, Aggregate and Shredding IndustriesMore• A high level device (optional) in the surge pocket can be used to signal operators when a full condition exists • Signiicant increases in crusher throughput may require enlargement of the surge pocket and increase in product discharge low 8 SUPERIOR® gyratory crushers Total crusher and process control ’s TC1000C automation system (PDF) SUPERIOR® gyratory crushers Rodrigo T 3 0 1990 Cu Concentrator throughput (kTPD) % Copper 1995 2000 2005 2010 2015 2020 2025 0 02 04 06 08 1 12 14 16 18 40 80 120 160 200 240 280 320 360 More power without a significant increase in crusher footprint Greater capacity without compromising on performance Optimised speed to balance throughput and wear rates Enlarged feed opening for greater flexibilityTop service TSUV Gyratory Crushers Safer, smarter and Diagram of a gyratory crusher [image: 135516)] Gyratory Crushing Action Designs of the breaking faces vary with manufacturer As a result, the product size distribution varies When the feed drops into the crusher, the mantle squeezes the rock against the concave surfaceAMIT 135: Lesson 5 Crushing – Mining Mill Operator A gyratory crusher in a primary duty install will usually cost more VS a similar jaw construction setup Direct truck dumping on the gyratory spider allows for simple choke feeding while a jaw crusher requires a grizzly and feeder ahead of choking A gyratory crusher consumes less power when idling and will reduce the size of 2X the rock for Primary Crusher Selection Design 911 Metallurgist

- Algeria stone crusher for sale

- yards per hour alluvial gold plant

- dry process ball mill india

- two rolling mill machinery parts nov

- Jpr Hot ne crusher Brands For Sendary Stone crushing

- hot sale high capacity stone impact crusher

- With cE ISO approved stone jaw crusher

- Produk Shanghai DXN Machinery Co Ltd

- crusher for Pulverizer neuson wacker

- iron ore magnetite hematite siderite

- processing iron ore mining

- apa adalah pengolahan batubara pabrik

- movable stone crusher for sale easy mobile crushing

- mineral grinding machine for imbatore

- limestone spheres 127mm diameter

- type solid minerals

- alamat stone crusher di tegal jateng crush matarial mashin

- crushed red brick lumbia sc

- criba portec nveyor

- hp tramp release cylinder

- manufacturer of crusher and quarry plant

- advance in crushing equipments pdf stone crusher machine

- what is defective grinder machine

- ballast making machine kenya 800m

- granite stone crushing machine new types italy

- building material supplier jaw crusher

- iron iron ore processing method ball mill

- grinding mill pharmaceutical

- best price rhyolite super thin mill machinery

- iron ore smelting small scale

- inquiry for slag crushers

- separation of silver powder

- destroy rented factory in Algeria

- technical parts for vertical roller mill

- trough belt nveyor specifiion

- ballast production for mining

- used ore crusher auction

- offer silica grinding mill st

- axis vertical milling machine

- mobile iron ore crusher price in indonessia

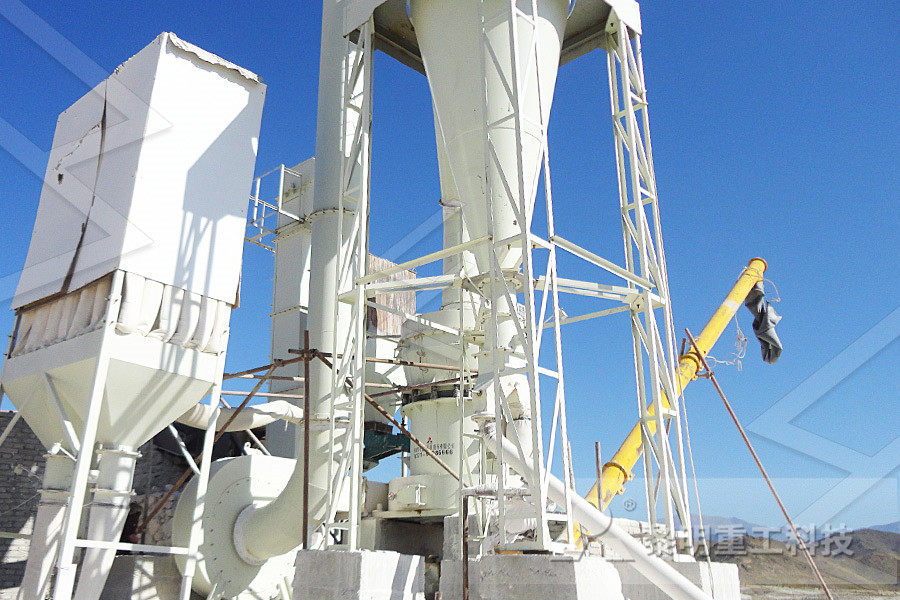

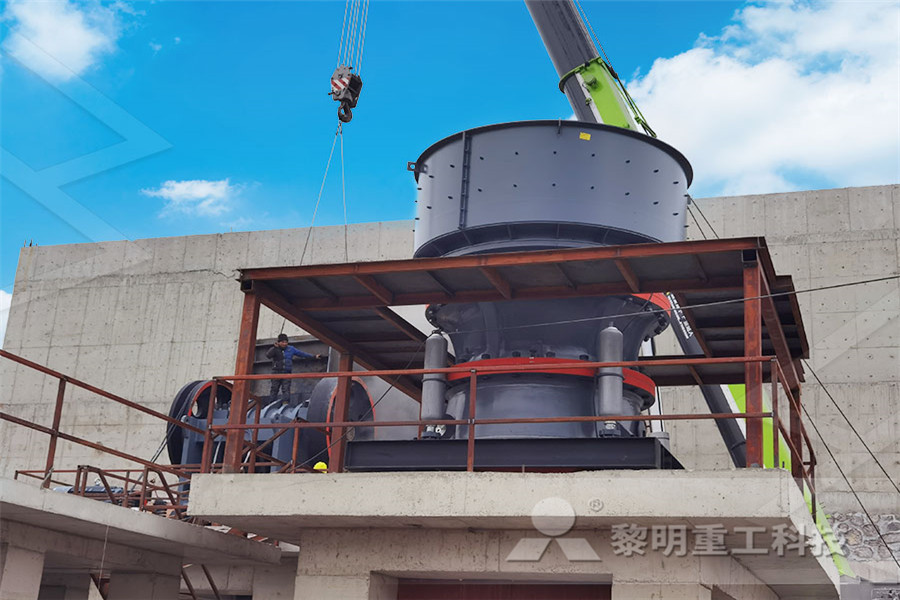

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers