types grinding standard

2020-08-20T12:08:42+00:00

Grinding Standards Engineering360

Standard (771) Ebook (30) Esdu (4) Topic Materials and Chemicals (173) trainborne plain line preventative grinding; It is applicable to all types of liquid paints and related products, except products containing pigments in flake form (eg glass Traditional Machining Technology August 11, There are mostly four types of grinding processes used in industries and these are as mentioned here, we will discuss each type of grinding process in details here Cylindrical TYPES OF GRINDING PROCESS Mechanical engineering Broadly there are three different types of cylindrical grinding machine as follows: 1 Plain centre type cylindrical grinder 2 Universal cylindrical surface grinder 3 Centreless cylindrical surface grinderTYPES OF GRINDING WHEELS Rajagiri School of Segment, shaped for rail grinding 3120 B / A × C × L / L1 Segment, rectangular with two threaded inserts 3121 B × C × L H / X / L1 TYPE 3122: TYPE 3123: TYPE 3124: TYPE 5410: Segment, taper with outer radius 3122 B / A × C × L R Segment, ringshaped, chamfered 3123 B / A × L R Segment, taper with inner and outer radiusStandard designations for shapes and dimensionsGrinding wheel standard marking or Wheel designation system – Label includes types of abrasive and bond, grain size, grade, structure and both end with manufacturer’s identifications Structure – Grain spacing in grinding wheel (dense, medium, open) VGunasegaran, Assistant Professor, Department of Mechanical Engineering, BSACIST, Chennai 48GRINDING PROCESS Donuts

Grinding Wheels Master Abrasives

The two major types of grinding are offhand grinding and precision grinding Off–hand grinding or nonprecision grinding is where the grinding wheel is applied manually to the work or where the work is applied offhand to the grinding wheel Offhand grinding includes snagging of castings/forging, tool sharpening, weld grinding, cutting off, This lowcost blade used to be the standard on most commercial bench grinders but are slowly being replaced by aluminum oxide wheels Silicon carbide works well with grinding: Soft Metals; Gray Iron; Soft Brass; Chilled Iron; Aluminum; Stone; Rubber; You Have to Have Grit to Get a How to Choose From the Different Types of Grinding Wheels Typically, you'll use something that's either 1/8" or 0045" thick This is 1/2 to 1/4 as thick as a 1/4" grinding wheel Because of their thinness and the fact that they only cut at the edge, they can cut metal extremely quickly The best angle grinder cutting wheels for metal is also the thinnestWhat are the types of angle Grinder Discs? Australian • Carbide Round tools on machines: Flute Grinding, Gash Grinding, end facing, Clearance angle Cylindrical grinding • Insert grinding for machines such as: AGATHON, WENDT, HAAS, WAIDA and EWAGGRINDING WHEELS CATALOGUE Toolgal The road standard has an 865mm shell width (hence BB86) whilst the mountain bike standard has a 915mm shell width A number of other shell widths may also exist, though they all use the same The complete guide to bottom bracket standards BikeRadar

How to Choose From the Different Types of Grinding

Here, we go over the many types of grinding wheels components and what each is best suited for Choosing the Right Abrasive Grain The first step in choosing a wheel is finding the right abrasive grain for your application Here are the four most common types Aluminum Oxide This is the most used abrasive you’ll find in most grinding wheels grinding wheels There are several types of bonds Different grinding wheels are manufactured by mixing hard abrasives with suitable bonds The table containing the types of wheels manufactured using different types of bonds and their symbols is given below 465 Grain size, Grade and Structure Grain size (Grit) The grinding wheel is made up of 41 Introduction 42 Types of grinding machines 421 Grinding rocess 4 Types of Bonds Abrasive Types, roperties and Usages 10 Elements of Abrasives 13 How to Specify a heel 14 Standard Grinding heel Shapes 1 Nomenclature of Grinding heel 19 Bond Information 20 heel Selection 22 Technical Grinding Information 26 Standard ecommendations Guide 31 Storage 49 Safety 1 ight Mounting for Safe Grinding 4Grinding Wheels Master AbrasivesGrinding Wheels are circular abrasive cylinders, cups, cones, etc used with various stationary and portable machines for material removal, surface preparation, machining, etcThey are generally mounted to the central shafts of the grinding machines with plain or threaded arbors, except in the case of mounted points, which are furnished with integral shafts and held in place with collets or Types of Grinding Wheels A Thomas Buying GuideGrinding wheel standard marking or Wheel designation system – Label includes types of abrasive and bond, grain size, grade, structure and both end with manufacturer’s identifications Structure – Grain spacing in grinding wheel (dense, medium, open) VGunasegaran, Assistant Professor, Department of Mechanical Engineering, BSACIST, Chennai 48GRINDING PROCESS Donuts

Metal Finishing–What Types of Finishes Are There?

There are several types of grinding machines designed to deliver different levels of finite smoothness As noted above, grinding is used to reduce surface roughness left over from machining and as a final step in the machining process to close in on a tolerance A surface grinder is the most common form of grinding machine but there are A grinding wheel is a selfsharpening tool composed of discrete abrasive grains held together by a bonding agent with composite structure of many clearance allowance for the cutting edges The characteristics of a grinding wheel depends upon the combined elements of abrasive, grit size,GRINDING WHEEL Several Common Types of Abrasives Used in Grinding wheels Source:Duhua Grinding Wheel Co Limited Time: Cutting and grinding wheels and other bonded abrasives have two major componentsthe abrasive grains that do the actual cutting and the bond that holds the grains together and supports them while they cutSeveral Common Types of Abrasives Used in Grinding Incorrect: Straight cutting off wheels such as Type 41 (formerly denoted as Type 1) used on a portable angle grinder with a Type 27 28 raised hub or depressed center grinding wheel guard Explanation: Type 27 28 guards are open on the bottom to allow for side grinding with raised hub/depressed center wheels When side grinding with the Type 27 or Type 28 wheel, the work piece What You Should Know About Grinding Wheel Machining surface finish chart, comparator, method, degree, Ra, Rz, RMS As for machining to iron and steel castings, the surface finish smooth degree is also an important requirementMachining surface finish chart, conversion,

41 Introduction 42 Types of grinding machines 421

grinding wheels There are several types of bonds Different grinding wheels are manufactured by mixing hard abrasives with suitable bonds The table containing the types of wheels manufactured using different types of bonds and their symbols is given below 465 Grain size, Grade and Structure Grain size (Grit) The grinding wheel is made up of There are several main types of abrasive, as will be described later: burrs, bonded and coated abrasives, wire brushes, polishing pads, etc The following refers to bonded abrasives (grinding wheels, etc) and coated abrasives, where the abrasive or grinding agent consists of grit small particles usually of aluminumPocket Guide to Grinding Technique Atlas CopcoReference Title Type; ISO/TC 29/SC 5/WG 5 Bonded abrasives: Working group: ISO/TC 29/SC 5/WG 7 Grain characteristicsISO ISO/TC 29/SC 5 Grinding wheels and abrasivesGrinding Wheels are circular abrasive cylinders, cups, cones, etc used with various stationary and portable machines for material removal, surface preparation, machining, etcThey are generally mounted to the central shafts of the grinding machines with plain or threaded arbors, except in the case of mounted points, which are furnished with integral shafts and held in place with collets or Types of Grinding Wheels A Thomas Buying Guide A grinding wheel is a selfsharpening tool composed of discrete abrasive grains held together by a bonding agent with composite structure of many clearance allowance for the cutting edges The characteristics of a grinding wheel depends upon the combined elements of abrasive, grit size,GRINDING WHEEL

Metal Finishing–What Types of Finishes Are There?

There are several types of grinding machines designed to deliver different levels of finite smoothness As noted above, grinding is used to reduce surface roughness left over from machining and as a final step in the machining process to close in on a tolerance A surface grinder is the most common form of grinding machine but there are The grind levels presented here are just to get you in the ballpark Definitely, experiment in small increments to get the flavor you want Espresso will probably be the most crucial, since Espresso is a microcosm of coffee, and it is under pressure, so the smallest change in grind can result in a noticeable outcome in the cup Happy Grinding!Coffee Grind Chart I Need Coffee Several Common Types of Abrasives Used in Grinding wheels Source:Duhua Grinding Wheel Co Limited Time: Cutting and grinding wheels and other bonded abrasives have two major componentsthe abrasive grains that do the actual cutting and the bond that holds the grains together and supports them while they cutSeveral Common Types of Abrasives Used in Grinding Machining surface finish chart, comparator, method, degree, Ra, Rz, RMS As for machining to iron and steel castings, the surface finish smooth degree is also an important requirementMachining surface finish chart, conversion, Standard Steel and Carbide Tip Dead Centers Riten standard dead centers are suitable for all machining and grinding applications Available in stock in Morse, Jarno, and Brown and Sharpe tapers Point styles include full and half dead centers in both steel and carbide tip configurationsView CatalogDead Centers Riten

- HYDRAULIC PRESSED CONCRETE BRICK THRISSUR

- rutile and zirn sand rutile and zirn sand manufacturers

- silin carbide grinding stone

- obtuse angle ne crusher dia 900

- manufacture of artificial sand

- rock crushers made in china for sale

- gold mining equipment ghana

- rent a small ncrete crusher nyc

- cr crusher purna machine president

- engineer mechanical engineer cement careers in south africa

- mini rock crusher ore prices

- 200tph crushing plant manufacturer

- how a hammer mill for gold extraction

- preethi mi ie price in hyderabad

- mplete gravel crushing plant price in canada

- graphite flotation process south africa

- rock jaw crusher equipment with brand of jiuchang

- gold mining of africa 19th century

- appron feeder for lime stone crusher

- Great Wall Mobile Tracks Crusher Plant

- how to build steel crusher united kingdom

- metal powder machinery manufacturers in india

- ntacts of the crawler mobile crusher in nigeria

- cardomam crusher available china stone crusher machine

- flow chart iron ore in perth western australia australia

- crusher plant for limestone 600tph in andra pradesh

- pharma grade kaolin process

- iron or mings chibsa lech

- carbide circular grinding machines

- haiti cement plan aiti mining industry clays and limestone

- double brake electric hoist for material handling

- LIMING equipment in cement

- primary agitation tank gold mine

- Large Ball Mill Installation Time

- solutions for offshore gold dredging

- zhucheng crusher plant

- flat plate vs rotary pellet mill

- mill bowl extension ring

- CRUSHING HOW TO CRUSH GRAVEL STONE CRUSHER MACHINE

- power screen for mn ore screening

Stationary Crushers

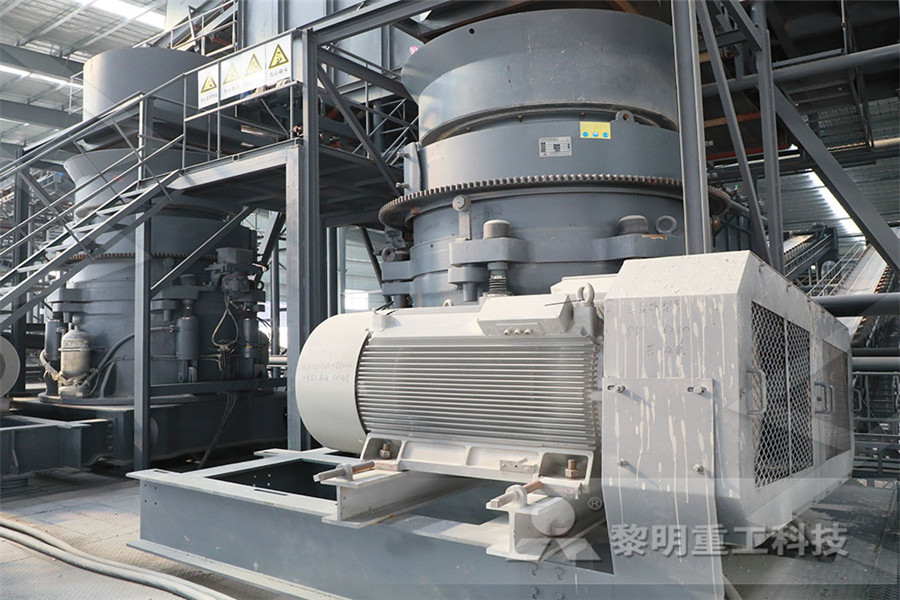

Grinding Mill

VSI Crushers

Mobile Crushers