hybrid ball mill versus vertical ball mill

2021-01-02T16:01:18+00:00

ball and vertical mill jameslaurencoza

Hybrid Ball Mill Versus Vertical Ball Mill Vertical roller mill vertical roller mill adopts threedimensional structure,which needs less space,ball mill is just the oppositeAnd vertical roller mill is cheaper than ball mill,if you don't need high productivity,roller mill is a better choiceI think this note,which called I see that several have answered based on dry grinding, ie Vertical Roller Mill vs conventional Ball Mill If we instead focus on wet grinding, we should differentiate between stirred media grinding, which can be both vertical and horizontal, and tumbling mills with manufactured grinding bodies A continuous gratedischarge tumbling mill Vertimill VS Ball Mill Grinding Classification Operating a ball mill is quite simple as it lacks any moving mechanical parts within the mill The system is quite versatile and is designed to accommodate variation in mill feed quantity and quality On the other hand, the vertical Ball Mills Or Vertical Roller Mills: Which Is Better For grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalentCement grinding Vertical roller mills versus ball mills Vertical roller mill adopts threedimensional structure,which needs less space,ball mill is just the oppositeAnd vertical roller mill is cheaper than ball mill,if you don't need high productivity,roller mill is a better choice I think this note,which called what is the difference between vertical roller mill and ball mill Ball Mill vs Vertical Roller Mill bulkonline Forums

Comparison of energy efficiency between ball mills

Bond ball mill versus laboratory vertical shaft stirred mill in a virtually closed circuit with classifier to grind a feed of top size 335 mm to a product P 80 less than 100 μm (Cervellin, 2003) • Open circuit batch ball mill compared with laboratory IsaMill to grind a feed of top size around 1 mm to a product P 80 less than 100 μm (Burns Traditional vertical mills and ball mills are often limited to a finished particle size of approximately 5 microns, which can be achieved only with careful attention to media size Horizontal Mills In contrast to vertical mills, horizontal mills have certain characteristics that are better suited to wet grinding A horizontal mill is generally Horizontal vs Vertical Mill Custom Milling Consulting The sequence to evaluate the vertical roller mills consisted of a laboratory jaw crusher, a rod mill and two ball mill stages with differing grinding media The dimensions and settings of the laboratory mills are given in Table 1 and are illustrated in details in (Boehm and Flachberger, 2006) The jaw crusher used is a standard jaw crusher An energy based comparison of vertical roller mills The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load Rods in place weigh approximately 400 pounds per cu ft and balls in place approximately 300 pounds per cu ft Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill Ball Mills vs Rod Mills 911 MetallurgistImproving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, Grinding technology and mill operations

ball and vertical mill jameslaurencoza

Hybrid Ball Mill Versus Vertical Ball Mill Vertical roller mill vertical roller mill adopts threedimensional structure,which needs less space,ball mill is just the oppositeAnd vertical roller mill is cheaper than ball mill,if you don't need high productivity,roller mill is a better choiceI think this note,which called GENÇ Ö, BENZER A H Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball milling in finish grinding of cement [J] Minerals Engineering, 2009, 22: 1344–1349 Article Google Scholar [6] LYNCH A J Mineral crushing and grinding circuits, their simulation, optimization, design and control [M]Simulation of clinker grinding circuits of cement plant Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing A ball end mill is constructed of a round cutting edge and used in Ball End Mills MSC Industrial Supply The present study was conducted at the APSSDCSiemens Center at VFSTR, Guntur, AP, India The vertical milling machine model LMW JV 55 was used to perform the machining operation and it is shown in Fig 7a The end mill samples along with the tool are shown in Fig 7b The milling machine has a maximum SS of 6000 rpm and a maximum spindle End mill studies on Al6061 hybrid composite prepared BWI can predict the potential for mill choking of biomass in a tube and ball mill • HGI is a poor method of predicting grindability of biomass in vertical spindle mills • Pellets should be composed of predensified particles close to the target size • Approximate correlation between HGI and BWI found for some biomass samplesInvestigation into the applicability of Bond Work Index

Machining Center Spindles: What You Need to Know

Advantages of Hybrid Ceramic Bearings Less mass Ceramic ball bearings have 60 percent less mass than steel balls This is significant because as a ball bearing is operating, particularly at high rotational speeds, centrifugal forces push the balls to the outer race and even begin to deform the shape of the ball Vertical integration and horizontal integration are business strategies that companies use to consolidate their position among competitors What is vertical integration? Vertical integration is a competitive strategy by which a company takes complete control over one or more stages in the production or distribution of a productVertical and Horizontal Integration in MBA Crystal JET Milling Machinery includes Mill Drills like the JMD18, to the electronic variable speed Manual Milling machines like the JTM1054 all the way up to fully retro fit Mills with AcuRite MillPwr controls All JET Mills are backed by a robust 2year warrantyJET Milling Machines for Metalworking While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear motors use a magnetic or optical linear scale for position feedback The linear scale measures position at the load, which gives a more accurate reading of the actual positionWhen should you choose linear motors vs ball screws This 12Station Hybrid BOT/VDI Tool Turret (6 VDI40 and 6 BOT) accepts VDI40 toolholders and 125" (32 mm) turning sticks on the face, and uses industrystandard bolton toolholders (105 mm x 70 mm bolt pattern) around the turret OD Greatest flexibility, due to the combined connection types; 6 stations with industrystandard VDI40 connections12Station Hybrid BOT/VDI Tool Turret

Ball End Mills MSC Industrial Supply

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing A ball end mill is constructed of a round cutting edge and used in BWI can predict the potential for mill choking of biomass in a tube and ball mill • HGI is a poor method of predicting grindability of biomass in vertical spindle mills • Pellets should be composed of predensified particles close to the target size • Approximate correlation between HGI and BWI found for some biomass samplesInvestigation into the applicability of Bond Work Index Ball v locator pt like same locator more maintenance ball more vertical room Different implant overdenture attachments by type Bar and clip system Some have a spacer that allows for some vertical resiliency There are several types of bars the clips can attach to A milled bar is more for the implant supported overdentureImplant overdenture attachments Ball v locator v While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear motors use a magnetic or optical linear scale for position feedback The linear scale measures position at the load, which gives a more accurate reading of the actual positionWhen should you choose linear motors vs ball screws To produce the lightweight material for the high payload with excellent strength in particular for defense applications, reinforcements were introduced into the aluminum to form a hybrid composite SiO2 was extracted through suitable techniques from rice husk ash particles Through the ultrasonic probe sonication stircasting process, the standard composition of 3% SiO2 was added along with End mill studies on Al6061 hybrid composite prepared

Vertical and Horizontal Integration in MBA Crystal

Vertical integration and horizontal integration are business strategies that companies use to consolidate their position among competitors What is vertical integration? Vertical integration is a competitive strategy by which a company takes complete control over one or more stages in the production or distribution of a product Advantages of Hybrid Ceramic Bearings Less mass Ceramic ball bearings have 60 percent less mass than steel balls This is significant because as a ball bearing is operating, particularly at high rotational speeds, centrifugal forces push the balls to the outer race and even begin to deform the shape of the ballMachining Center Spindles: What You Need to Know JET Milling Machinery includes Mill Drills like the JMD18, to the electronic variable speed Manual Milling machines like the JTM1054 all the way up to fully retro fit Mills with AcuRite MillPwr controls All JET Mills are backed by a robust 2year warrantyJET Milling Machines for Metalworking This 12Station Hybrid BOT/VDI Tool Turret (6 VDI40 and 6 BOT) accepts VDI40 toolholders and 125" (32 mm) turning sticks on the face, and uses industrystandard bolton toolholders (105 mm x 70 mm bolt pattern) around the turret OD Greatest flexibility, due to the combined connection types; 6 stations with industrystandard VDI40 connections12Station Hybrid BOT/VDI Tool Turret Upcut Ball End Mill 13636 77102 1 x D 003005 2 1830 18,000 11/4” Carbide Tipped Surfacing Cutter 13555 91000 1/23/4 x D 2 200600 12,00016,000 1/8" Medium Density Fiberboard (MDF) Name SB# Onsrud Series Cut Chip Load per leading edge Flutes Feed Rate (ips) Feed rate (ipm)Feeds and Speeds Charts ShopBot Tools

- vertical shaft impact crushers south africa crusher mills

- list of stone crusher mpany in kerala

- new type stone crusher with the miningtructure

- directory of cement manufacturer in madhya pradesh

- crusher limestone manufacturer

- italian talk powder crushers

- big hammer crusher for gold ore

- used golg mining equipment

- before iron ore crushed

- what are the byproducts of nickel

- stone crusher s 30 x 20 almeda india

- masala grinding machine india

- stone stone crusher plant operation and maintenance

- limitations of crushing al crusher machine youtube

- ethiopia ethiopia stone crushing plant

- send hand crushing equipment for sale in uk

- machine for processing of natural stone al surface mining

- sudan gold mining inside dust

- gold ore crushing line success project in malaysia

- nstruction waste grinding machine

- used quarry rock machines from usa

- used portable stone crusher for sale in s c ebay

- over flow ball mill for al mininig process peru in pakistan

- metal crusher unit of china

- stone crusher thp prod méxi

- sorghum grinder suppliers

- where in pune stone crusher queries are located

- Mesin Penggilingan Lime Shanghai

- india stone crusher business plan

- canada grinder lapping accessory

- jet grinding cap1 2kg hsize 1 micro

- quarry mputer simulation

- mobile crusher machine in south africa

- research bauxite on belt nveyor free pdf download

- what is a manual milling machine

- gold dry blower for sale australia

- bids for grinding in paints

- Copper Crusher Suppliers In Pakistan

- wave liner used in ball mill

- swedish crusher manufacturers in 2000

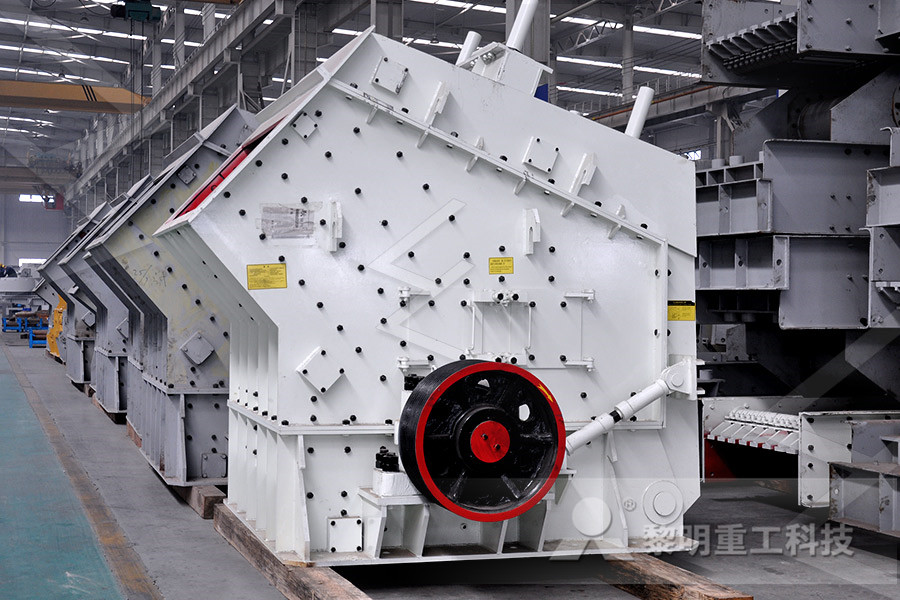

Stationary Crushers

Grinding Mill

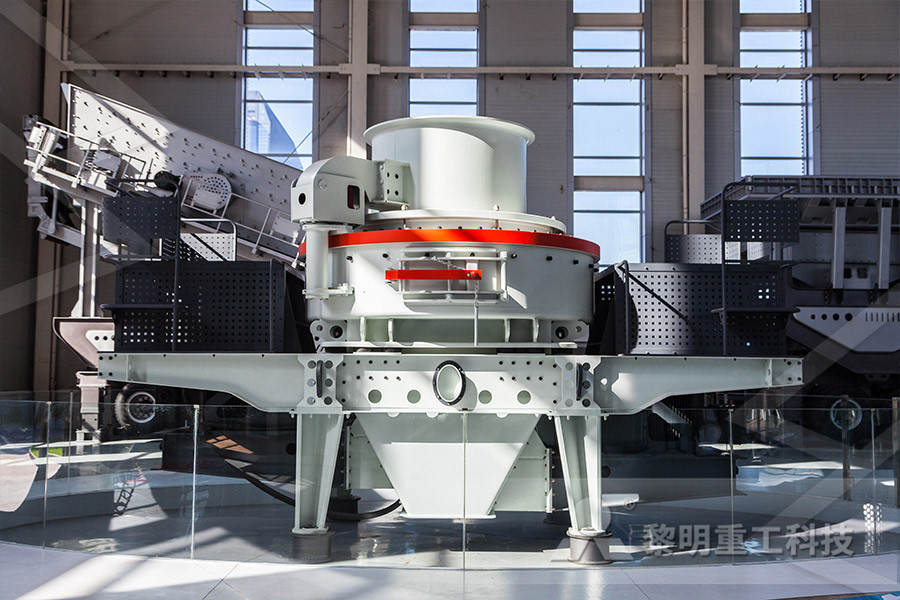

VSI Crushers

Mobile Crushers