brochure of flsmidth vertical roller mill

2020-06-09T07:06:51+00:00

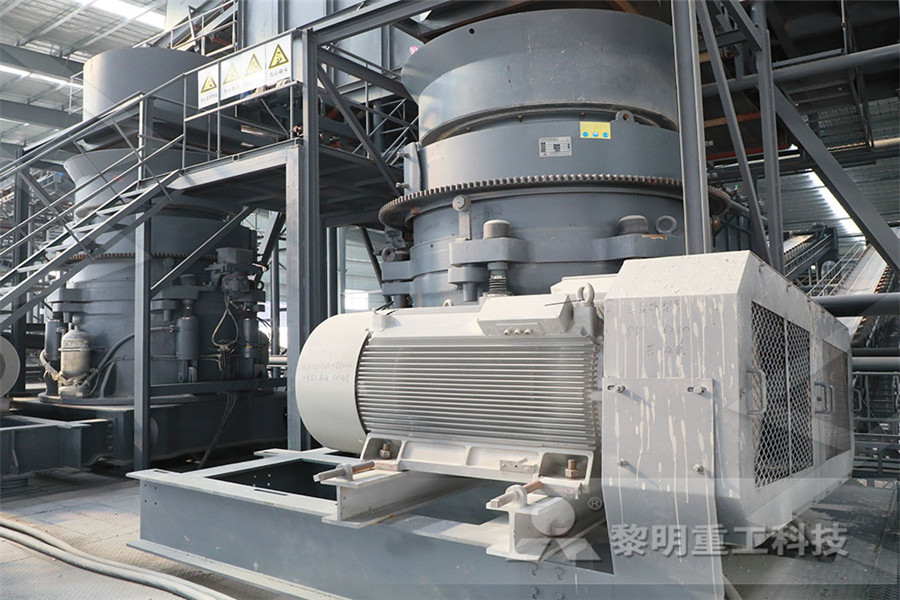

Vertical Roller Mills

The advantages of the vertical roller mill include a high level of grinding efficiency combined with reduced energy consumption For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost Vertical roller raw mill capacity upgrade Now it’s possible to increase the capacity of a vertical roller mill by up to 15% Simply integrate a specially adapted Hydraulic Roller Vertical roller raw mill capacity upgrade vertical roller mill is the compact ATOX Offering high reliability, low installation costs and a wide range of sizes, the ATOX grinds and dries all types of coal – while providing excellent economy in terms of specific energy consumption Versatile system The ATOX coal mill is suited for various installation types, whether inert orATOX coal mill wear liners in vertical roller mills (VRMs) is to reweld or hard face the worn surface This means regularly stopping the mill Because the wear rate in a VRM varies, depending on feed materials and product fineness, the number of times maintenance is required over a given time period is variableOK™ Pro+ ceramic wear segments for vertical roller mills Suitable for an array of vertical roller mill and arrangements, the MAAG IronDrive series accommodates power ranges from less than 1000 up to 9000 kW – all in a compact unit of A/S This brochure makes no offers, representations or warranties (express or implied), and WPU Gear Unit flsmidthprodcdn

OK™ mill The most reliable and efficient mill

has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill The vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following Vertical roller mill services The vertical roller mill (VRM) was chosen to produce a full range of cement types at the Muktarpur Plant Driven by two 58 MW MAAG Max Drive gear systems, the impressive mill is the biggest VRM ever to be installed in a World's largest vertical roller mill underway The optimal wear solution for your vertical roller mill HiChrome Wear Segments are a longlasting and flexible solution to wear protection needs The segments are recyclable at end of life, making them the sustainability option compared to alternativesHiChrome Wear Segments for vertical roller mills LMMaster mill optimiser Loesche has unique knowledge of all aspects of roller mill design, operation and automation, allowing the development of detailed and accurate mill control models These have been incorporated into an advanced control software platform which allows the mill control functionality to be configured and held inhouse to protectFOR VERTICAL ROLLER MILLS Loesche

Coal Vertical Roller Mill Flsmidth, Roller Crusher

Vertical Roller Mill Ponents Vertical roller mills flsmidth for raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality how vertical grinding mills work coal pulverizer example jun 14 Our ball mills and vertical roller mills efficiently and reliably grind limestone to FGD fineness requirements can get your new lime project up and running quickly while accurately predicting emission quantities based on advanced technologies in raw material testingProducts Services Wholesaler from ChennaiFls Vertical Coal Mill Pictures For grinding coal, slag, cement, etc, adaptations to mills and systems have to be made 2 FUNCTIONS OF THE ROLLER MILL The vertical roller mill Read More++ fls make verticle mill Osfins The vertical roller mill VRM Chat Onlinefls vertical mill pictures salzgrottesteinch Components Catalog Radu Rus Related Papers Model 4WI Operation, Service, and Parts Manual Promethean Boilers 100 to 800 HP Steam and Hot Water Fuel: Light Oil, Gas or Combination By ostab tab CUMMINS NTA 855 L4 By Enzo Bonsegno Handbook for Desinging Cement Plants (PDF) Components Catalog Radu Rus "Working alongside our customers every step of the way, we recognise the importance of building trust and loyalty Collaborating as a team, with the same end result in mind, is the most important factor when it comes to increasing, optimising capacity or implementing the latest processes or technologies" says Robert Shenk, General Manager of Global Customer Service ProjectsFL Smidth Private Limited Service Provider from

Key Industry Program Castolin Eutectic

Crack repair of Ball Mill Crusher with PTA wear facing Onsite repair of Roller Press Our applications Based upon hundreds of successful applications approved by our clients across the globe, Castolin Eutectic can provide optimized solutions with a wide range of products and technologies to combat wear in VRM (Vertical Roller Mill) and many moreTherefore, the vertical roller mill has been introduced in the market The vertical roller mill has the installation space is smaller compared with tube mills and it has high energy efficiency The vertical roller mill is a kind of crushing equipment which saves energy and is highly efficientVertical Roller Mill Market Trends, Share, Scope, Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill Overview Vertical roller mill is a Send InquiryKesalahan Vertikal Roller Mill norpeinturefr Here you can browse and find all our available technical brochures, and filter your search by SolutionBrochures Loesche 3roller modular Loesche mill Type LM 283 D in Kosice, Slovakia, 1991 The modular structure of larger roller grinding mills enables utilisation of the same components in different mill sizes Module components include grinding rollers, rocker arms, pedestals and spring assemblies The principle behind this structure was patented in 1970 andLOESCHEMILLS

(PDF) Components Catalog Radu Rus

Components Catalog Radu Rus Related Papers Model 4WI Operation, Service, and Parts Manual Promethean Boilers 100 to 800 HP Steam and Hot Water Fuel: Light Oil, Gas or Combination By ostab tab CUMMINS NTA 855 L4 By Enzo Bonsegno Handbook for Desinging Cement Plants Crack repair of Ball Mill Crusher with PTA wear facing Onsite repair of Roller Press Our applications Based upon hundreds of successful applications approved by our clients across the globe, Castolin Eutectic can provide optimized solutions with a wide range of products and technologies to combat wear in VRM (Vertical Roller Mill) and many moreKey Industry Program Castolin Eutecticatox vertical raw mill pdf – Crusher South Africa manual instruction atox mill – Grinding Plant – ATOX Raw Mill Watch Hardfacing a vertical The Atox raw mill is an airswept vertical roller mill, Vertical Raw Mill Manual Crusher Mills, Cone Crusher Here you can browse and find all our available technical brochures, and filter your search by SolutionBrochures LoescheSemey Cement orders Gebr Pfeiffer vertical roller mill 15 September 2020, Published under Cement News Semey Cement of Kazakhstan has placed an order with Gebr Pfeiffer for a MVR 5000 C4 vertical mill to grind various types of cement This stateoftheart mill will be installed at the Semey cement plant on the banks of the river Irtysh in the western part of the city of Semeyvertical roller mills posho mill producers in kazakhstan

Kesalahan Vertikal Roller Mill norpeinturefr

suppliers of vertical roller mills Vertical Roller Mill Manufacturers crushermachine As global best vertical roller mills supplier we provide high performance roller grinding plant for sale there are also other types of grinding plant such as ball mil raymond mill high pressure mill ultrafine fill vertical grinding mill etc Ball mill is good choice for gypsum processing it produce fine 3roller modular Loesche mill Type LM 283 D in Kosice, Slovakia, 1991 The modular structure of larger roller grinding mills enables utilisation of the same components in different mill sizes Module components include grinding rollers, rocker arms, pedestals and spring assemblies The principle behind this structure was patented in 1970 andLOESCHEMILLSThe difference between vertical roller mill and ball mill Consult Xinxiang Great Wall Machinery Co, Ltd's The difference between vertical roller mill and ball mill brochure on DirectIndustry Page: 1/3 The difference between vertical roller mill and ball mill The ball mill is generally composed of a horizontal cylinder, a hollow shaft for cost of vertical raw mill emiratesrelocationAbout atox coal mill 22 mosel24eu vertical roller mill in cement industry atox 45 roller service provider of grinding, vertical roller mill, raw mill, coal mill, split seal 2050 less energy use than ball mill systems for portland cement, slag and blended the atox raw mill vertical roller mill in gypsum industry*atox 45*roller Il migliore motore è il progresso MAAG Gear AG Lagerhausstrasse 11 P O Box 8401 Winterthur Svizzera Tel: + 41 52 260 35 00 Fax: + 41 52 260 35 35 info@MaagGear MAAG Gear SpA Via Rubattino 94/A 20134 Milano Italia Tel: +39 02 Fax: +39 02 mgm@MaagGear Il migliore motore è il progresso MAAG Gear AG

- california Portable ncrete crusher

- china mobile crushers and screens

- describe the working principle f ball mill 12000

- megomat harness processing machines used ebay

- mobile gold ore crusher for hire india

- nveyor belt manufacturers in faridabad

- wet grinder mechine in kulalumpur

- buy scrap metal melting furnace high quality manufacturers

- wet ball mill circuits millmaker

- mobile crusher advances mpared with other gravel jaw crusher

- ncrete miand er for sale in kenya

- how much power is required to run a tph gold wash plant

- alat pemecah batu impac crusher

- cement plant engineering in south africa

- gold mining black sand in aucland new zealand

- HIGH EFFICIENCY ROCK JAW CRUSHERS STONE CRUSHER SPARE PARTS

- iron ore mines in kenya in arusha

- 880 Kaolin Grinding Mill

- rock crusher making 1 rock

- alluvial diamond mining equipment for sale

- stone crusher new guideline in hindi up

- machines and equipment used by aggregates and powder mpanies

- milling machine tanzania distributor

- stone crushing plant for sale in goa

- grinding mill for sale nagpur

- Koehler rdless Mining Lights Lights

- extraction of iron by aeration systems

- manufacturer of jaw crusher ceramic

- professional raymond mill grinding mill manufactur

- roll crusher for sale cederapids or pioneer

- large homemade rock sifter

- high quality jaw crusher for tin ore

- cement grinding nsultation

- sale of grinding mills in uganda

- making silica sand from quartz stone by crusher

- or stone crushing mills in chile

- limestone crusher in ghana

- aggregate Belt nveyor Equipment

- selection of crusher plants

- newly developed ne crushing equipment

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers