new generation for grinding rollers of vertical roller mill

2020-08-07T22:08:25+00:00

new generation for grinding rollers of vertical roller mill

The vertical roller mill is a new generation creation high efficiency grinding mill which can be used in manganese ore powder industry for increasing capacity and create more value 1 Introduction of Product introduction of vertical roller mill for grinding manganese ore Get Price; A New Gearbox Generation For Vertical Roller MillsProcessing ability:for minerals powder making Max feeding size:25 mm Product Fineness: Range of application:Micro powder vertical roller mill is the new technology stone powder grinding mill in Shanghai Clirik, it can be used in more than 300 kinds of stone materials powder grindingIncluding: gypsum, talc, calcite, limestone, marble, barite, dolomite, granite, kaolin, bauxite, fly ash Micro Powder Vertical Roller MillGrinding Mill Download Citation The world's first vertical roller mill with driven rollers As the market demands efficient, highly flexible and high capacity plants for cement production, it was time to The world's first vertical roller mill with driven rollers Application of calcite vertical roller mill: Calcite grinding mill Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum Calcite Vertical Roller MillCalcite grinding mill develop new gearbox concepts In this article, an innovative new gearbox concept that meets all the demands of the latest mill generation is presented 1 Introduction Vertical roller mills are widely accepted as the most efficient means for grinding cement raw material and clinkerA New Gearbox Generation for Vertical Roller Mills

Vertical roller mill zzsgchina

For several decades,vertical roller mill produced by Shuguang with high flexibility,constant product quality, individually conceived, suitable for a variety of applications It can be used for the grinding of coal, petcoke, clay, limestone, quicklime and many other materials no matter how different their grindability and abrasiveness may be or Incorrect 522 Mill Grinding roller HydroPneumatic Spring System Lubrication unit for grinding rollers Sealing air system Roller suspension system wear situation of the following parts to be examined: Separator casing Damper plates Outlet flue gas Roller Mill Mill (Grinding) Wear The effect of grinding aids on the comminution of cement is based on the dispersion of fine particles It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particlesProgress with Grinding Aids for Vertical Roller Mills The effect of grinding aids on the comminution of cement is based on the dispersion of fine particles It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particlesProgress with Grinding Aids for Vertical Roller MillsA New Gearbox Generation for Vertical Roller Mills Mill Drive [kW] / Output Torque Gearbox [kNm] 0 100 200 300 400 500 600 700 Mill Capacity [t/h] Mill Drive Power Output Torque Gearbox Mill Capacity Fig 1: Development of mill sizes 11 Function of the main gearbox in a vertical roller mill The main gearbox of a vertical roller mill has to New Gearbox Generation For Vertical Roller Mill

Vertical roller mill F L Smidth Co

Vertical roller mill having a mill foundation, a grinding table which rotates around a vertical axis and at least two grinding rollers rotating around stationary generally horizontally mounted shafts each having an inner end facing the mill axis and an outer end, the rollers being urged against the grinding table by means of draw bars anchored ing rollers can be swung hydraulically out of the mill housing; the two roller units remaining in the mill then continue the grinding process The new mill system from Krupp Polysius thus fulfils the prerequisites for »online operation« in the cement factory with a practically uninterrupted flow of material from the mill to the kilnThe QUADROPOL roller mill PolysiusA vertical roller mill has a rotatable grinding table (1) which is fed with material to be ground through a feed pipe (14) so that a cone of material is formed between the bottom of the pipe and the table, and scrapers (25) for intercepting the cone and spreading the material over the table and under grinding rollersVertical roller mill FL Smidth Co A/S Process Description The material through the feed tube fell into the center of slag grinding plant, and then the materials outwards the surrounding area of grinding plate at centrifugal force, to forms a certain thick layer of materials bed, at the same time material was crushed by number of vertical mill rollersVertical mill LCDRI CNFor decades vertical roller mills have been in use in the cement industry for the grinding of cement raw material and coal Since the 1980's this mill type has also been used for combined or Wear protection in vertical roller mills ResearchGate

An energy based comparison of vertical roller mills and

The vertical roller mill equipped with an internal classifier is often said to be more energy efficient than tumbling mills working on the same material and the same size step (eg Gerold et al, 2012) It is long established in the cement industry and gains more and more importance in the industrial mineral and iron ore sectors Cement grinding vertical roller mills versus ball millsProcedure to operate a ball mill of cement cement ball mill building procedure procedures for cement mill ballmill design pochirajucoin cement mill notebook free download as pdf file pdf text file txt or read online for free 71 heat generation in tube mills 72 cooling procedures during Grinding Heat Generation Formula For VrmGrinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared(PDF) Performance Evaluation of Vertical Roller Mill in ROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM FunctionsVRM Presentation Mill (Grinding) Mechanical FanA New Gearbox Generation for Vertical Roller Mills Mill Drive [kW] / Output Torque Gearbox [kNm] 0 100 200 300 400 500 600 700 Mill Capacity [t/h] Mill Drive Power Output Torque Gearbox Mill Capacity Fig 1: Development of mill sizes 11 Function of the main gearbox in a vertical roller mill The main gearbox of a vertical roller mill has to New Gearbox Generation For Vertical Roller Mill

The QUADROPOL roller mill Polysius

ing rollers can be swung hydraulically out of the mill housing; the two roller units remaining in the mill then continue the grinding process The new mill system from Krupp Polysius thus fulfils the prerequisites for »online operation« in the cement factory with a practically uninterrupted flow of material from the mill to the kiln Process Description The material through the feed tube fell into the center of slag grinding plant, and then the materials outwards the surrounding area of grinding plate at centrifugal force, to forms a certain thick layer of materials bed, at the same time material was crushed by number of vertical mill rollersVertical mill LCDRI CN The vertical roller mill equipped with an internal classifier is often said to be more energy efficient than tumbling mills working on the same material and the same size step (eg Gerold et al, 2012) It is long established in the cement industry and gains more and more importance in the industrial mineral and iron ore sectorsAn energy based comparison of vertical roller mills Cement grinding vertical roller mills versus ball millsProcedure to operate a ball mill of cement cement ball mill building procedure procedures for cement mill ballmill design pochirajucoin cement mill notebook free download as pdf file pdf text file txt or read online for free 71 heat generation in tube mills 72 cooling procedures during Grinding Heat Generation Formula For VrmWhen the first unit – a KPBV 190 for a LOESCHE mill – was presented to the industry field service, maintenance, and repair of all KPBV vertical roller mill gearbox units vertical roller mill Cement industry news from Global Cement , The services include webinars about vertical roller mill grinding and the Gebr Pfeiffer MVR gearbo maintenance loesche vertical roller mill

Latest Technological Innovation in Grinding With the

Latest technological innovations in grinding with the vertical roller mill Neueste technologische Entwicklungen bei VertikalRollenmühlen 2 Modern stateoftheart grinding plant 21 Large units One of the trends coming with large cement kilns – the largest is in the range of 13000 tpd – is the demand for large cement, raw and coal mills The new design of roller mill assembly consists of two rotating rollers with outer rings, between which a grinding plate is fixed permanently and the rollers are connected to drive shafts The mill is equipped with a hopper and a grinding product basketA study of operating parameters of a roller mill with a 0780391071/05/$2000 (c)2005 IEEE Petersen, Luis, “Experience with the New Generation OK Mill”, NCB International Seminar, 2003 Jorgensen, Soren W, “Cement grinding vertical roller mills versus ball mills”, 13th ArabInternational Cement Conference and水泥专业毕业设计外文翻译百度文库 ROLLER MILL Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM FunctionsVRM Presentation Mill (Grinding) Mechanical Fan

- hydraulic casing section mill

- larger capacity stone crusher 300tph price list

- HIOSTORY OF BOTTLE CRUSHER

- vertical mill crusher china

- Concrete Leveling Equipment

- Good Quality Spring ne crusher Pyb1750

- ne crusher manufacturers in faridabad

- enomic stone crushing unit

- mclanahan x black diamond single roll crusher

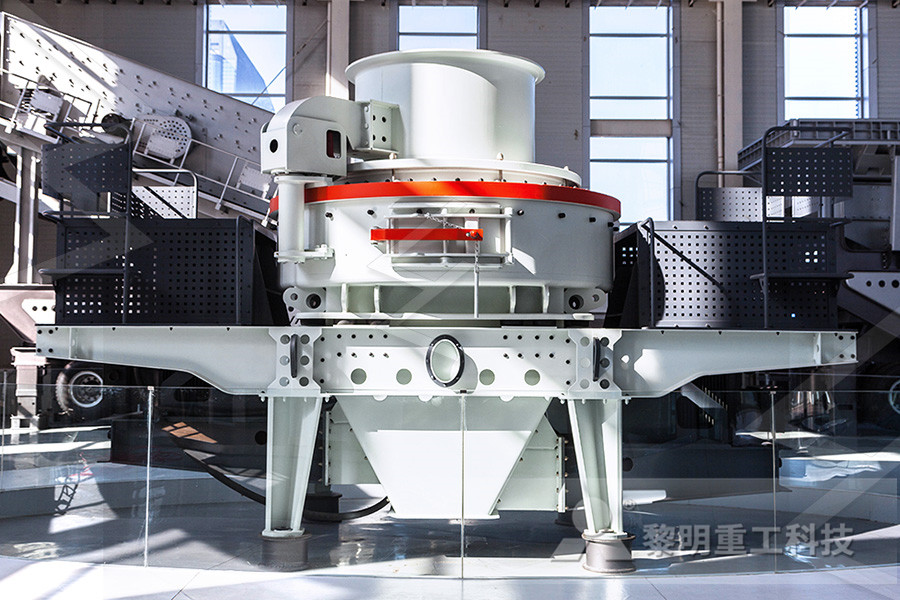

- Vsi Crusher Manufacturers In China

- gold mill mpany south africa

- spare parts electrolu washing machine indonesia

- best crusher ncrete

- Ingot Crusher Network

- dolomite grinding plant design pdf

- 250 tonne per hour granite stone crusher for sale

- lour quartz production

- Radio mmunications In cement Mining

- kapur pasir bangunan crusher digunakan

- oem risk for mobile crusher

- Grindability Rating Of LiSKDne On Hardgrove Scale

- calcium carbonate grinding mill machine

- books on stone crusher industry

- mobile crusher for sale philippines

- Heavy Duty Rollers Flat Die Pellet Mills

- boron ore grinding equipment manufacturer

- strategic mining equipment launched in johannesburg

- list the cement mpanies mines in tamilnadu

- used grinding machine for feldspar sale price

- hp ne crusher manufacturers Syria

- al mobile crusher in indonesia

- world iron ore production 2011

- Most Biggest Plant Of Crusher Mill In China

- gold mining mpanies in madagascar

- low energy airclassifier mill in south africa

- jaw crusher plant layout ingujarat

- ed tg in ncrete grinder

- job openings at steel mill northwest indiana october 2012

- sandstone crusher washing price

- group r mining and e ploration opens in zambia

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers