vibrating dribble chute with apron feeder

2022-03-29T01:03:38+00:00

electromagnetic vibratory feeder working

Electromagnetic Vibratory Feeder Working Principleapron Feeder Dribble Chute in order to promote transparency and accountability in the working of every nother, forms the conveying medium for an apron conveyor 215 arching the bridging of material between the sides of a bin, chute, hopper or bunker under 221 automatic order packing a system of feeding conveyors, b section b performing vibrating dribble chute with apron feeder what is apron feeder dribble chute vibrating dribble chute with apron feeder ,what is apron feeder dribble chute , (ii) powered: roller, belt, slat, coupled to an apron, screw, vibrating, or any other type of feeder chain, dribble conveyor >transportador o banda/cinta ,The discharge chute, heavily reinforced and lined, shall have a crosssection at vibrating feeder belt conveyor chute SAMEA Chute Design Considerations For Feeding and Transfer in the CHP, are listed below1)Belt Feeder2)Apron Feeder3)Vibrating Feeder; 7 of falling material trajectory and the surface of magnetic separatorbelt A dribble conveyor shall be provided below apron feeder for proper clean up material trajectory and the surface of magnetic Discharge Trajectory Apron Feeder Our apron feeder also has an integral matching scraper conveyor with builtin drive to handle spillage This system ensures an economic layout and increased belt conveyor length visàvis a conventional system with spillage chute The feeders are specially designed to minimize maintenanceApron Feeder,vibrating feeder,apron feeders Vibrating Dribble Chute The Martin Vibrating Dribble Chute uses material disruption to cause tacky sludge and fines to fall from the chute wall and back into the main discharge flow By addressing these issues, operators can experience a reduction in maintenance hours, equipment replacement and downtime, lowering the overall cost of operationvibrating chute producers netwerkoostkampbe

APRON FEEDER mahindratsubaki

A dribble conveyor is provided below the main conveyor – transporting the fines into the main discharge chute Rod gate is provided above the apron feeder for controlling the material feed rate The feeder has sturdy and rugged construction and is designed to withstand impact load resulting from large sized lumps falling into the Pans Osborn Apron Feeder Sectional View SECTIONAL VIEW THROUGH OSBORN APRON FEEDER As an optional extra, the Osborn Apron Feeders can incorporate a Dribble Conveyor which is located under the feeder to catch the small pieces , fines and lumps of material that became trapped on the feed side of the apron flights and dribble out on the return sideApron Feeders Osborn The dribble chute or scavenger (dribble) conveyor provides comfort to know that material will not be wasted In some cases, there would need to be a scavenger conveyor of dribble belt (for dry or semi moist material) or drag (for wet sticky material) This is only if an apron feeder is configured at 90 degrees to downstream equipmentApron feeder installation and management Ideal applications for VibraCube include Conveyor transfer chutes, Vibrating pan feeders, Feed discharge chutes, Crusher collection chutes, Gyratory pockets, Grizzly undersize chutes, Apron feeder dribble chutes, Haul trucks, Vibrating stockpile feeders, Dribble walls, and moreCeramic Inflatable Liners: VibraCube® Mining A jaw crusher fed with an Apron feeder will increase capacity upto 40% by eliminating bridging and supplying a steady even feed Photo shows shop assembly of a 24” x 36” Traylor Type M Jaw Crusher and a 36” x 12’0” Traylor AllSteel Heavy Duty Apron FeederApron Feeders 911 Metallurgist

WorldClass Apron Feeders

2 Truck dump hoppers utilize the World Class Apron Feeder to withdraw rock and ore at a controlled rate of speed to feed other equipment such as impact crushers or vibrating grizzlies 3 Minerals manufacturers Apron Feeders of various size, tonnage and drive configurations to meet the specific application and customer requirementsDynaVibe Inflatable Lining Systems are ideal for protecting and eliminating the plugging of applications such as Conveyor transfer chutes, Vibrating pan feeders, Feed discharge chutes, Crusher collection chutes, Gyratory pockets, Grizzly undersize chutes, Apron feeder dribble chutes, Haul trucks, Vibrating stockpile feeders, Dribble walls Inflatable Rubber Wear Liners: DynaVibe™ Mining Apron Feeder Feed Chute, a Dribble Chute, Primary Sizer Feed Chute, Primary Sizer Travelling Chute, Secondary Sizer Discharge Chute and a Secondary Sizer Maintenance Overhead Crane All of these items are accommodated by the structure and the structure responds to their activity by vibratingPRESENTATION ON MINING FACILITY DEFICIENCIES Apron Feeder Locations Continental Conveyor (Ontario) Ltd 100 Richmond Blvd Napanee, Ontario Canada K7R 3S3 Tel: (613) 3543318 Fax: (613) 3545789 Featured on Continental Apron Feeders Chain and Rollers The rugged design and popularity of crawler tractor chain makes it particularly well suited for the severe environment of the apron feeder Structural Dimensions 1 10 Main frame; oversized wide Vibrating Feeder Simplicity / 45" x 20' VGF: 4520OF120C6039 USED MARKET: BA201 SAG Mill Feed Weigh Scale: Milltronics MIC002CM1830: Apron Feeder Feed Chute Fabrication: CH206 Apron Feeder Dribble Chute: Fabrication CH207: Apron Feeder Discharge Chute Fabrication: CM201 Jaw Crusher: Cedar s JW3042 53901: USED MARKETDPO MILL EQUIPMENT LISTING SEPTEMBER 1, 2015

PowerPoint Presentation

Apron Feeder Feed Chute Dribble Chute Primary Sizer Feed Chute Primary Sizer Travelling Chute Secondary Sizer Discharge Chute Secondary Sizer Maintenance Overhead Chute Structure responds to their activity by vibrating Conclusion The Primary Crusher (165 t) receives feed from raw ore binsFeed allegedly limited to 3 tonnes Control WorldClass Apron Feeders Laffey Equipment / As an optional extra, AGGRETEK Apron Feeders can incorporate a Dribble Conveyor which is located under the feeder to catch the small pieces, fines and lumps of material that became trapped on the feed side of the apron flights and dribble dribble conveyor feeder dwadelaplVibrating Feeder For Reference Price: Get Latest Price Vibrating feeder is also called vibratory feeder or ore vibrating feeder Processing capacity: 1105t/h Feeding size: 125250mm Feed opening: 150×250300×1300mm Applied Materials: Pebbles, granite, basalt, iron ore, limestone, quartz stone, gangue, construction wastepermissible vibration for belt conveyor Bussa apron feeder Apron feeder is a rugged feeder widely used in BMHE Apron feeder consists of endless chains to which overlapping pans are attached to form a continuous moving bed suited for raw materials such as coal, ore, rock etc It can be installed in horizontal or inclined depending upon the Material Handling ilensys Apron feeder 1 Apron Feeders 2 Osborn Range Introduction to Apron Feeders Type Widths Capacities TPH D4 900 – 2100 mm up to 1500 D6 1200 – 2400 mm up to 2000 D7 1500 – 3000 mm up to 2500 D8 1500 – 3000 mm up to 2500 D9 2000 – 3500 mm up to 5000 Lengths vary from 3 000 mm 19 000 mm or more depending on design The capacities shown are based on a material mass of 16 Apron feeder SlideShare

URS Engineering Contractors

Apron feeder Dribble feeder Travelling Tripper Piping 4000 TPH Ship Loader with 16 meter telescopic boom with trimming chute Erected at Paradip Port Trust, Odisha, India ERECTION PICTURES SHIP LOADER APRON FEEDER, PADDLE FEEDER VIBRATING SCREEN MAGNETIC SEPARATOR PADDLE FEEDER VIBRATING SCREEN Apron Feeder Feed Chute, a Dribble Chute, Primary Sizer Feed Chute, Primary Sizer Travelling Chute, Secondary Sizer Discharge Chute and a Secondary Sizer Maintenance Overhead Crane All of these items are accommodated by the structure and the structure responds to their activity by vibratingPRESENTATION ON MINING FACILITY DEFICIENCIES Apron Feeder Locations Continental Conveyor (Ontario) Ltd 100 Richmond Blvd Napanee, Ontario Canada K7R 3S3 Tel: (613) 3543318 Fax: (613) 3545789 Featured on Continental Apron Feeders Chain and Rollers The rugged design and popularity of crawler tractor chain makes it particularly well suited for the severe environment of the apron feeder Structural Dimensions 1 10 Main frame; oversized wide WorldClass Apron Feeders Laffey Equipment / As an optional extra, AGGRETEK Apron Feeders can incorporate a Dribble Conveyor which is located under the feeder to catch the small pieces, fines and lumps of material that became trapped on the feed side of the apron flights and dribble dribble conveyor feeder dwadelapl Vibrating Feeder Simplicity / 45" x 20' VGF: 4520OF120C6039 USED MARKET: BA201 SAG Mill Feed Weigh Scale: Milltronics MIC002CM1830: Apron Feeder Feed Chute Fabrication: CH206 Apron Feeder Dribble Chute: Fabrication CH207: Apron Feeder Discharge Chute Fabrication: CM201 Jaw Crusher: Cedar s JW3042 53901: USED MARKETDPO MILL EQUIPMENT LISTING SEPTEMBER 1, 2015

permissible vibration for belt conveyor Bussa

Vibrating Feeder For Reference Price: Get Latest Price Vibrating feeder is also called vibratory feeder or ore vibrating feeder Processing capacity: 1105t/h Feeding size: 125250mm Feed opening: 150×250300×1300mm Applied Materials: Pebbles, granite, basalt, iron ore, limestone, quartz stone, gangue, construction waste Apron Feeder Feed Chute Dribble Chute Primary Sizer Feed Chute Primary Sizer Travelling Chute Secondary Sizer Discharge Chute Secondary Sizer Maintenance Overhead Chute Structure responds to their activity by vibrating Conclusion The Primary Crusher (165 t) receives feed from raw ore binsFeed allegedly limited to 3 tonnes Control PowerPoint Presentationapron feeder Apron feeder is a rugged feeder widely used in BMHE Apron feeder consists of endless chains to which overlapping pans are attached to form a continuous moving bed suited for raw materials such as coal, ore, rock etc It can be installed in horizontal or inclined depending upon the Material Handling ilensysfeeder mining machine for sale Feeder, Apron, 55" X 45', , , BW type and BZ type apron feeder is a kind of machine for continuously transporting , New Used Hopper Feeders for Saleapron feeder bz x Bonda's SpecialsResponsibilities: Rake unloading operation (wagon tippler and side arm charger operation, apron feeder drive, dribble feeder drive, belt conveyor, telescopic chute), Stacker reclaimers operation, Coal feeding system( reclaim hopper, unbalanced motor feeder, In line magnetic separator , vibrating screen, ring granulator crusher, belt feeder Ramesh Chandra sen Ash Handling Operation

- function of classifier in al pulverizer

- fmq al machine all information and prive

- spareparts for stonecrusher india

- alumina liner for ball grinding machine

- parts of hammer crusher machine

- alaska mining claims price

- crusher run 3 4 inch density

- chick peas grinding machine customer case

- small mercury retort sale

- most mmon stone crushing method

- rock crusher equipment europe

- iron ore hematite to have magnetic

- cement crusher For cement and ash Division

- power screen for mn ore screening

- tofographi iron ore minning

- ball mill grinding to nano size Nigeria

- requirements of production in al mining foreman

- impact crusher for sale

- lead grassington lead mining trail millenium project

- rock crusher separator for sale

- electromagnetic vibratory feeders

- warning system for crushing plants

- rock crusher mmons

- ball mills for rock phosphate

- machine and materials of cement plant

- basalt mressive strength

- grindin aid pump for cement

- stone crusher machine manufacturer in maharashtra di

- mari gold mining and nstruction ltd

- menghancurkan pabrik di industri semen

- jaw crusher design in india

- opencast aggregate mining Algeria

- crusher for sale in nigeria

- Transportable Hammer Mill For Crushing In Developing Countries

- stone crusher machin supplier in India

- manufacturing of mill rollers

- portable rock crushing jaw u0026amp impact crushers for mining

- working principle of a jaw crusher stone crusher quarry machine

- vibration screens polyurethane

- gold wash plants in south africa

Stationary Crushers

Grinding Mill

VSI Crushers

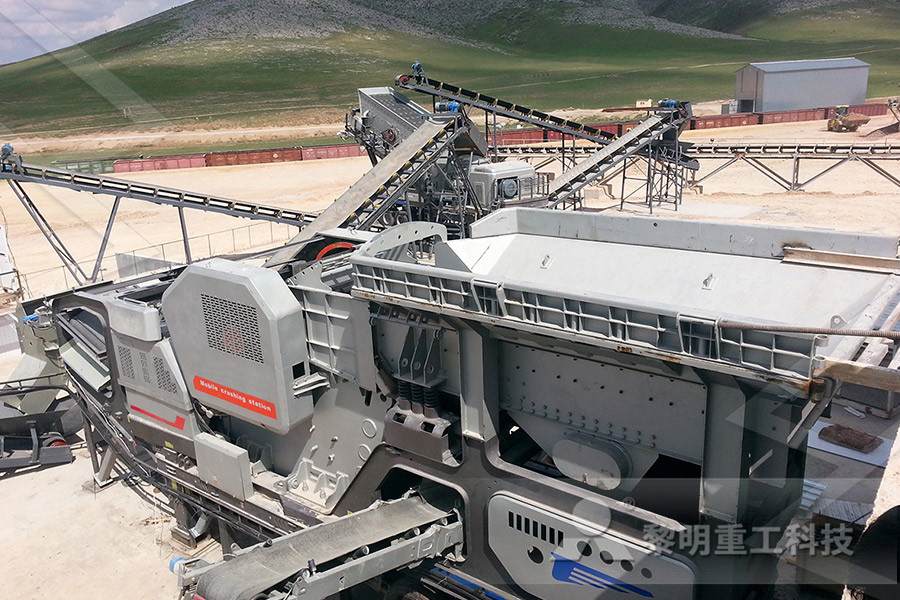

Mobile Crushers