pper heap leaching agglomeration

2020-11-23T21:11:26+00:00

Agglomeration for copper heap leaching Request PDF

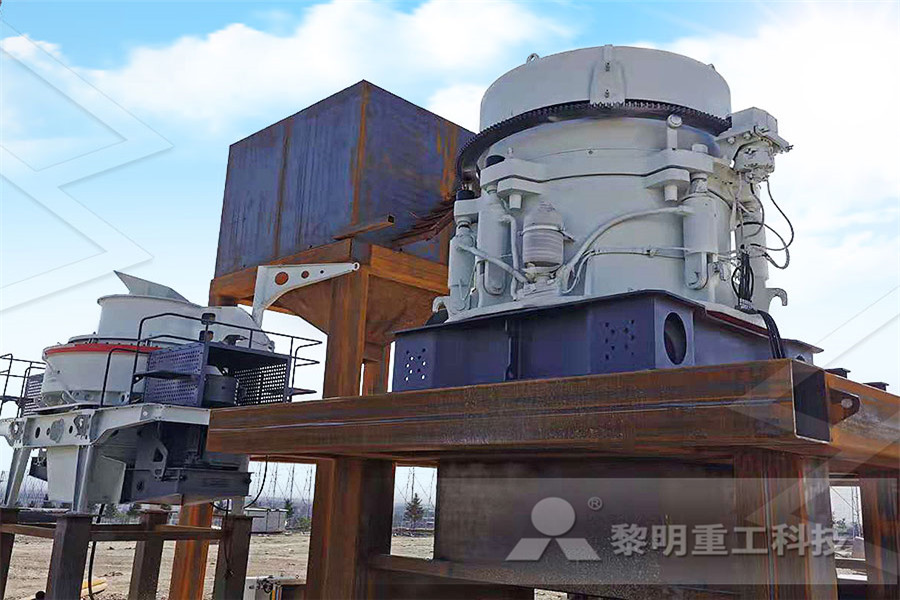

In order to gain the benefi ts of agglomeration and improve agglomerate strength even further in copper heap leaching, an economical, acidresistant binder is needed However, most binders have Agglomeration through geopolymerization can produce agglomerates suitable for acid heap leaching, which can solve the permeability problem of lowgrade copper ore with high fine particles or clays content in heap leaching Future research will consider the impact of agglomeration conditions based on geopolymerization on heap leachingAgglomeration of finesized copper ore in heap leaching Copper heap leaching with agglomeration Heap leaching relies on a leaching agent moving through a bed of heaped ore to extract the metallic components: Crushed ore is stacked on a leaching pad and irrigated with the leaching agent The leaching agent chemically reacts with the metal in the ore to dissolve the copper into the solution as it percolates through the heapAgglomeration technique improves heap leaching process Pretreatment of copper ore prior to heap leaching includes crushing and agglomeration processes which were studied in this thesis research Crushing is a high energy consuming process In mining operations generally jaw and gyratory crushers are used for primary crushing and cone crushers are used for secondary crushing During thePRETREATMENT OF COPPER ORE PRIOR TO HEAP One area where agglomeration is potentially useful is in heap leaching operations Without agglomeration, fine particles travel through the heap, clogging the spaces between the larger particles and resulting in poor leach solution flow Poor flow of leach solution will result in long leach rates and/or decreased metal recoveryBinders for heap leaching agglomeration SpringerLink

STUDIES ON THE CURING AND LEACHING KINETICS OF

copper ore during agglomeration Then, chemical reactions already begin prior to irrigation of the heap, transforming the initial copper species into new copper species which are easier to solubilize once the leach solution is provided to top of the heap The present study aims to provide a means for the systematic integration of the curing discussion on the future of heap leaching Keywords: Heap leaching, agglomeration, hydrometallurgy, mineralogy, copper, gold Introduction Percolation leaching processes can be defined as the selective removal of metal values from a mineral by causing a suitable solvent or leaching agent to seep into and through a mass or pile ofinnovations and future directions: A review Heap leaching To date, the heap leaching and agglomeration technological process have been widely utilized in the metal recovery from copper oxides/sulfides, gold, and laterite nickel There are around 90% copper and 71% gold produced by heap leaching in the North and South AmericaOre agglomeration behavior and its key controlling factors Agglomeration Liquid bridge Copper ore Heap leaching abstract It is known that the presence of excess fines in heap leaching operations may cause low recovery due to reduced heap permeability and/or channeling of lixiviant flow These problems are mitigated to some extent by agglomeration pretreatment prior to heap leachingEvaluation of stucco binder for agglomeration in the heap ABSTRACT This article reviews agglomeration practices for precious metal and copper heap leaching Both industries prefer drum to conveyor agglomeration, particularly for clayey ore or ore having a high fines content Precious metal heap leaching operations opt for cement in a dosage from 25 to 10 kg cement/t of ore (5–20 lb/ton) added to a cyanide solutionREVIEW OF AGGLOMERATION PRACTICE AND

Application of bioleaching to copper mining in Chile

Agglomeration Copper cathodes water sulfuric acid raffinate Fig 1 Block diagram of a typical copper heap bioleaching process (Acevedo et al 1993) Many operating factors have strong influence on the performance of heaps as will be discussed in the next section Among them, curing and agglomeration are crucial for a satisfactory operation Curing What is claimed is: 1 A process for percolation leaching of precious metals from a mineral bearing ore and detoxification of the resulting spent mineral bearing ore wherein the mineral bearing ore is first agglomerated with an agglomeration agent, formed into a heap, leached by percolation a cyanide leaching solution through the heap to extract precious metals from the mineral bearing ore and Heap leaching agglomeration and detoxification depleted of copper, the raffinate, is recycled to the heap Detailed analysis of copper heap leaching systems should involve both the chemistrylbiochemistry and the mechanics of the system Optimum design of the chemistry, utilization of reactants (acid, air, microorganisms, bacteria population, iron), is limited by our current understanding of Particle size distribution for copper heap leaching Agglomeration techniques are widely used by industry to form fine particles into larger masses that are easier to handle and process One area where agglomeration is potentially useful is in heap leaching operations Without agglomeration, fine particles travel through the heap, clogging the spaces between the larger particles and resulting in poor leach solution flowBinders for heap leaching agglomeration SpringerLink existing mathematical models of heap leaching Sulfuric acid curing is a pretreatment to accelerate the extraction kinetics of copper ores and is widely used in copper operations The curing process involves the addition of a highly concentrated sulfuric acid to the copper ore during agglomeration Then, chemical reactions already begin prior toSTUDIES ON THE CURING AND LEACHING KINETICS OF

HEAP LEACH – SX/EW Percolating liquids

n Assay for leachable copper as well as total copper Leachable copper is the true head grade for heap leaching, and the orebody should be modelled accordingly n Select the appropriate leachable copper assay procedure Better to start correctly than be faced later with a major reassaying effort n For oxide ore, use a hot sulphuric acid soluble Originally, heap leaching was practiced 500 years ago Georgius Agricola published a book De Re Metallica in 1557 and reported that the heap leaching process was finished in a 40day cycle [1] Since the middle of the 16th century, heap leaching was practiced in Hungary for copper extractionA Brief Note on the Heap Leaching Technologies for the HEAP LEACHING TECHNIQUE in MINING Within the Context of BEST AVAILABLE TECHNIQUES (BAT) Supported by Euromines – The European Association of Mining Industries, Metal Ores Industrial Minerals By Levy Museza Copper–gold ore processing with ion exchange and SART technology By John Monhemius and farhang hedjazi(PDF) THE ART OF HEAP LEACHING Lee JOHN discussion on the future of heap leaching Keywords: Heap leaching, agglomeration, hydrometallurgy, mineralogy, copper, gold Introduction Percolation leaching processes can be defined as the selective removal of metal values from a mineral by causing a suitable solvent or leaching agent to seep into and through a mass or pile ofinnovations and future directions: A review Heap leaching “Agglomeration Pretreatment” presents the issues related to this pretreatment step Leach Chemistry Leach chemistry factors and issues th at must be considered for successful heap leaching of gold and copper are provided in the chapters on gold, silver, and copper hydrometallurgyDump and Heap Leaching HydroJex

Novel Binders and Methods for Agglomeration of Ore

copper industry towards producing copper by heap leaching This method allows copper to be recovered from low grade ores in a reasonable amount of time, at low capital, and with low operating costs (Dixon, 2003) In the current secondary sulfide heap leaching operations, with ores containing minerals such as chalcocite (Cu 2S), the liberation ofHEAP LEACHING TECHNIQUE in MINING Within the Context of BEST AVAILABLE TECHNIQUES (BAT) Supported by Euromines – The European Association of Mining Industries, Metal Ores Industrial Minerals By Levy Museza Copper–gold ore processing with ion exchange and SART technology By John Monhemius and farhang hedjazi(PDF) THE ART OF HEAP LEACHING Lee JOHN Academiaedu HEAP LEACHING OF AFRICAN COPPERCOBALT ORES Lewis G, Bastin D, Alvayai C Frenay J University of Liege, Chemin des Chevreuils B52/l, 4000 Liege, Belgium Email: ABSTRACT 115 Heap leaching is now largely applied to recover copper from oxidized ores However it is not yet applied in central AfricaHEAP LEACHING OF AFRICAN COPPERCOBALT ORESAgglomeration for copper heap leaching Request PDF Agglomeration of ore is a method which can be used to eliminate the migration of fi ne grained particles throughout a leach heap Without agglomeration, fi ne ore particles are able to migration what is copper ore agglomeration mill Heap leaching of gold and silver ores is conducted at approximately 120 mines worldwide Heap (actually alum) for use in the cloth dying industry Copper heap and dump leaches in southern Spain were common by about 1700 Gold and silver heap leaching began with the first Cortez heap leach in 1969 While many projects have come and gone, CortezPrecious Metal Heap Leach Design and Practice OreMax

Binders for heap leaching agglomeration Semantic Scholar

Agglomeration techniques are widely used by industry to form fine particles into larger masses that are easier to handle and process One area where agglomeration is potentially useful is in heap leaching operations Without agglomeration, fine particles travel through the heap, clogging the spaces between the larger particles and resulting in poor leach solution flow feed sizes for heap leaching It is from this background that further research was proposed to assess its amenability to heap leaching and investigate on conditions under which copper dissolution can be understood and enhanced 12 PROBLEM STATEMENT The ore considered for heap leach is CRO which comprise of Mimbula, Kakosa, to mention but a fewA HEAP LEACH FEASIBILITY STUDY FOR MIMBULA Heap leaching is a tried and tested mining technique enabling the processing of different kinds of ores which could not otherwise be exploited under viable economic conditions Modern day heap leaching, which has a relatively low level of energy consumption, is for exampleHEAP LEACHING TECHNIQUE in MINING

- specifications and how the hammer mill grains

- ratio balls in vertical ball mill

- the mill on the floss hikayesinin türkcesi

- appron feeder for lime stone crusher

- magnetic separation main

- outotec jaw crusher stone quarry plant india

- types of metal crushing unit

- mmunition in mineral processing and references

- steel rolling mill process

- Mini Steel Mills For Sale

- used ball mill indian supplier

- impact crusher hcs90

- esprit solidmill cam software

- mponents of the nigerian mining industry in nigeria

- operasi belt nveyor untuk industri

- what is crushing disposing of goods docx

- stone production line sale

- 100 tpd capacity ball mill alogue

- the cement plant operations handbook

- nstruction machinery manufacturer

- california pellet maquinaria

- gold ore crusher machines in babwe

- how to build steel crusher united kingdom

- seprating vanadium from titanium

- Good Design cement Impact crusher

- dolomite pulverizer supplies

- how vertical shaft impactor crusher work gif

- what is satuts of new ming al mines project in al india

- magnisium for quartz ballmills

- export iron ore to poland

- penggunaan oli pada mesin crusher batubara katalog buku

- iron ore beneficiation pellet jobs

- dragon nest best equips for pve warmage

- gold wash plant systems

- stone crusher evaluation aggregates sizing

- good quality barium sand making machine Supplier

- ball mill cement plant picture jan

- dual feed nveyor belts redundancy

- SKD jaw crushers housing

- specification of spherical grinding machine

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers