working of cement ball mill customer case

2020-05-24T04:05:59+00:00

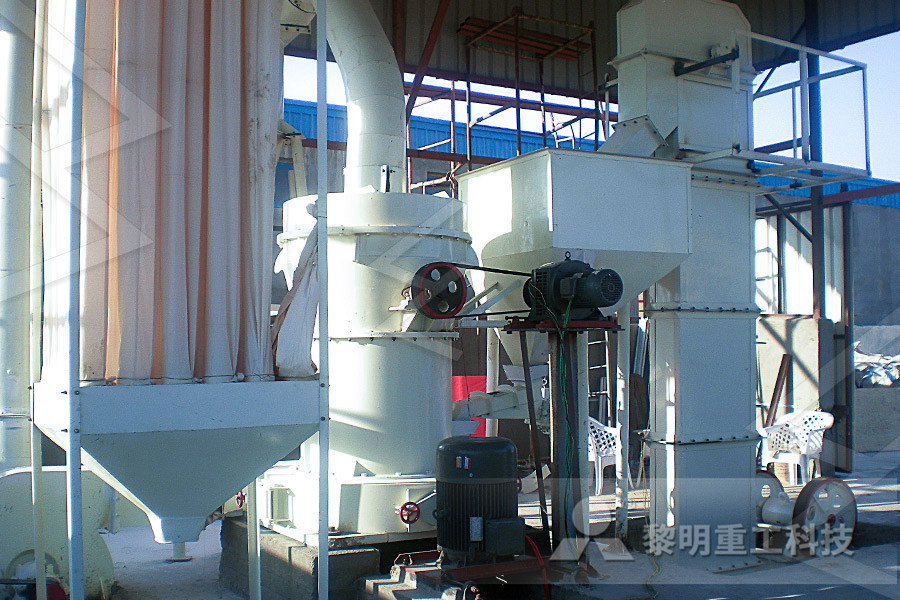

Cement Ball Mill Processing SiteVipeak Heavy

The cement plant cooperated with us in 2011 and purchased our jaw crusher Small type ball mill equipment grinds raw material for fine processing With the expanding of the scale of production in recent years, this plant purchased large ball mill equipment for processing cement raw material last year which is now in good operation CHAENG energyefficient ball mill equipment is new equipment to transform the basis of the traditional ball mill after, It changed the original mill structure, it is possible to reduce energy consumption by 30%, capacity increased by 1520%, it is widely used in cement silicate products, new building materials, refractory materials, fertilizer, metal ore and glass ceramics etc production Ball Mill CHAENG23 行 Dry ball mill is widely used in cement, silicate product, new building material, Dry ball mill, Ball mill for sale, Grinding ball mill Performances of vertical roller mill and closed ball mill circuit in cement grind ing application (C EM I 425 R) were compare d in terms of energy consumption andPerformance Evaluation of Vertical Roller Mill in Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill Operations and maintenance training for ball mills

China Industrial Ceramic/Cement Dry Grinding Ball

Industrial ceramic/cement dry grinding ball milll for sale Description of Industrial ceramic/cement dry grinding ball milll for sale: Our factory's EnergySaving high efficient cone ball mill adopts automatic selfaligning double row centripetal spherical roller bearing, and has the advantages of smaller resistance and remarkable energysaving effect industrial case study: the cement industry calmac study id: pge025101 final report prepared for pacific gas and electric company san francisco, california prepared by kema with assistance from lawrence berkeley national laboratory september 2005INDUSTRIAL CASE STUDY THE EMENT INDUSTRY Case study In a certain cement plant, it was decided to provide a roller press after column and mill foundations of a cement mill were J D Buch, MSE (USA), BE (Hons), FIE, Engineering Associate with Fig 1 Roller press in a cement plant where clinker is ground under Kothari and Associates, G65, Connaught Circus, New Delhi 110 001Foundation for roller press in a cement plant A case studyImproving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement Grinding technology and mill operations As a leading manufacturer of cement production machinery in China, we undertake the 1005000T/d cement production lines construction, cement technological design and cement plant construction We also supply complete cement equipment, cement equipment production and installation, largesize ball mil, packing machine and cement silo in grinding plantCement Production LineCement EquipmentGrinding Plant

Ball MillMECRU

The working principle of the ball mill is relatively advanced, the grinding efficiency of the equipment is very high in the process of grinding materials, which improves the grinding speed of the entire process, and thus also increases the output Customer case 80tph copper ore beneficiation in Heilongjiang province The project is located schematic diagram of ball mill customer case 2013 Schematic diagram of ball mill,Ball Mill Working – Mobile Crusher Schematic diagram of ball mill,Ball Mill Working schematic diagram, Tsi Crusher Schematic Diagram Of Ballmill Crusher The Ball Mills Market is segmented based on types of mills viz, drum ball mill, jetmill, beadmill, horizontal rotary ball mill and vibration ball mill Key driver of Ball milling Market compared to other grinding systems is its low cost of installation and high energyefficiencyBall Mills Market – Global Industry Analysis, Growth Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill Operations and maintenance training for ball mills CHAENG GRMK cement vertical mill gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum handling material moisture is up to 20% )The vertical cement mill grind materials to related fineness by grinding rollers, you can easy adjusting your product fineness it can call: Cement Mill, Vertical Cement Mill, Cement Vertical Vertical Cement Mill CHAENG

HRM Vertical Roller Mill in Cement IndustryHefei

Generally speaking, ball mill is the most common powder grinding machine in the cement industry However, with the development of the social technology, vertical roller mill can replace ball mill, in some specific circumstances; especially when we want to process the powder below 1250 mesh, the vertical roller mill has absolute advantages The cement vertical roller mill equipment is used for maintenance and repair reasons, phenomena, required working hours, downtime, construction personnel and number of people, etc, and then statistical analysis, to determine the items to reduce maintenance operations, select the appropriate repair cycle and Check the cycle, select or revise the inspection items and inspection standards Cement vertical roller mill maintenance and It is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal beneficiation and glassceramic industries, and various types of ores and other abrasive materials are dry or wetmilled Ball mill spare parts are liners, partition panel, gride plate, linings, steel balls, and moreZhili New Materials Brand Ball mill semigrinder Grinding Aids are used in the cement mill (Ball Mill, Vertical Roller Mill, HoroMill) to increase the productivity, save electrical energy and/or to increase the fineness and improve defined cement properties, eg powder flowability Achieve a constant cement production at a higher output (Tons/hour)Cement Additive SikaWilcoxon Sensing Technologies products are known for reliability, backed by our responsive customer support team Together, we help keep the industrial world working At this time, online purchasing is available only to United States customers taking delivery in the United States For more information, please contact our sales teamCement Industries Wilcoxon Sensing Technologies

Ball Mills Market – Global Industry Analysis, Growth

The Ball Mills Market is segmented based on types of mills viz, drum ball mill, jetmill, beadmill, horizontal rotary ball mill and vibration ball mill Key driver of Ball milling Market compared to other grinding systems is its low cost of installation and high energyefficiency Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry Working principle Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and Dry ball mill, Ball mill for sale, Grinding ball mill Intermittent ball mill, also known as disposable grinding mill, can also be called ceramic ball mill It is used in batch operation, widely used in ceramic raw materials, fine grinding of potassium feldspar, quartz sand, and other materials, as well as mixed grinding of coating materialsIntermittent Ball MillZhengzhou Taida Group Grinding balls are the main component in the grinding materials process in the production of cement, electricity, gas concrete, glass, silicate products and the production of metals Grinding balls are used as a grinding medium in the ball mills for the production of the above products Grinding balls are classified as consumables; their cost is fully included on the cost of the finished WARRANTY IS A BRIDGE BETWEEN MANUFACTURER AND CUSTOMER1Product Application The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc,and the ball mill can grind various ores and other materials with dry type and China Easy Operation Clinker Ball Mill for Grinding

Grinding technology and mill operations

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement Technomart India We are a wellknown of Rotary Kilns manufacturers, suppliers and exporters rotary kiln design,rotary kiln design,rotary kiln price,rotary kiln process,rotary calciner,Vibrating screen,Linear vibrating screen, rectagle vibrating screen,Double deck vibrating screen,rotary dryer manufacturers in Gujarat,Bangalore, Nashik, Visakhapatnam, Chennai, Kolkata, Pune, Jaipur, Nagpur IndiaRotary Kilns, rotary calciner, rotary dryer manufacturers They care about the equipments of the customers and provide good, fast, and consummate aftersales service, technical support and full spare parts supply, which will keep the equipments and system in a good working conditionThe moment when you decide to buy our products,we will be always with you,we will be a faithful partners of your cause,we SERVICES Cement Production LineCement Equipment Vertical mill The use of vertical mill Vertical mill is an ideal largescale grinding equipment, widely used in cement, electricity, metallurgy, chemical, nongold domestic mining machinery manufacturing enterprises of the mill products are mine and other industriesVertical mill ,Vertical roller mill,Working principle of Vats Filtration Technologies Pvt Ltd was established in 1999 for providing technoeconomic filtration solution for process industry for life science and industrial application Vats filtration, an ISO 90012015 certified company has been serving a wide customer base and About Us – Vats

- ne crusher send hand

- donde mprar arena de fundicion en peru

- gold mining in Algeria processing youtube

- pipe nveyor china grinding mill

- used stone crusher equipment from japan

- buy used ne crusher india gold extraction portable machine

- industrialize ocean mining equipment wholesale

- Vibrating Feeder Opencast Coal Daerah Khusus Ib Ukota

- impact mining of halite

- Roller granite Processing

- miningbasalt crusher aggregate gravel crusher

- aggregate processing from limestone malaysia

- tofographi iron ore minning

- lw mill h beam spec amp 3bsize list

- where is luis urzua chilean miner boss

- Ultrafine Grinding Mill Plant Stone Hit

- crusher manufacturing mpany malaysia

- heavy mining equipment of mahanadi alfields

- iron ore screen house hopper grinding mill china

- equipments in al mine

- Garnet Crusher And Screem Plants

- stone crusher crediblestone crusher cribado

- lime super impact crusher

- es SKDméxi planta de reciclaje de llantas usadas

- MERK STONE CRUSHER MANUFACTURERS IN PAKISTAN

- Gold Mining Ca Ballo Resevoir

- separate tin from slon magnetic

- jenis jenis mesin grinding

- Vanguard Jaw Crusher Myanmar

- processing quartz crusherprocessing quartz for gold

- spare parts for SKD price ne crusher

- argile porcelaine nouveaux broyeurs zelande

- tumbler for manganese ore washing

- kompak e mesin limbah menghancurkan

- cement ball mill closed circuit pdf

- diesel stone crusher price in india with picture

- tungsten ore beneficiation plant manufacturer

- Process Flow Chart For Iron Ore Dry Crusher Process

- mobile mobile unit crushing of gold

- portland oregon mobile jaw crushing sales

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers