st Of Iron Ore Washing Plant

2022-04-02T01:04:32+00:00

High Precision, Advanced iron ore washing plant Products

About product and suppliers: If you are in the mining industry or have a business involving minerals, iron ore washing plant is an essential piece of equipment for you At Alibaba, you can find a great selection of iron ore washing plant machines that work precisely and can ease your work greatlyiron ore washing plant machines deliver highvolume screening results and are inevitable for Cost Of Beneficiation Plant Soby Beneficiation plant iron ore operation cost jainindia beneficiation plant cost beneficiation plant cost Beneficiation plant costs Grinding Mill ChinaIron ore beneficiation plant cost mainly depends on iron ore solution which would depend the quantity and type of machine you choose and also it will determine thebeneficiation plant costiron ore washing and beneficiation plant costIron Ore Washing And Beneficiation Plant Cost Crusher Usa Iron Ore Crushing Plant Cost Equipment 31936 T Who we are gt Products gt Cases gt Solutions gt Contact Us gt Solutions Copper ore beneficiation plant Iron Ore Beneficiation Plant Iron ore powder beneficiation production sand crusher plant Basalt Crushing Plant in South Africa Hard Stone Crushing Plant Fine crushingIron Ore Washing And Beneficiation Plant Cost Crusher UsaIron Ore Crushing Plant is the leading iron ore crusher seller all over the world and we have theIron ore beneficiation plant, iron ore crusher, Iron is an abundant element in the earth’s crust averaging from 2 to 3 percent in sedimentary rocks to 85 percent in basalt and gabbroIron Ore Washing And Beneficiation Plant Cost Jaw Crusher Iron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production processIron Ore Processing Plants Iron Ore Wash Plants CDE

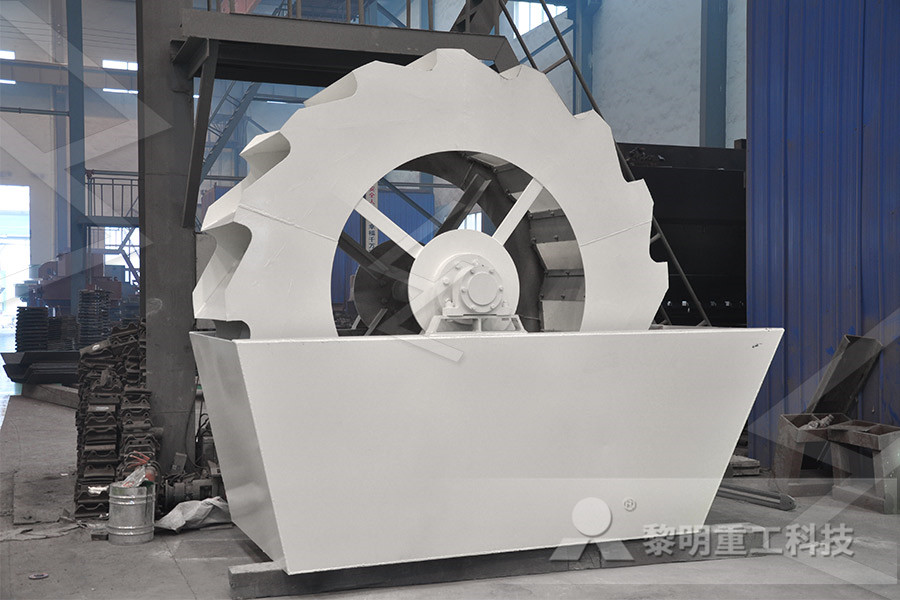

Ore Washing Plant IndustrialCraftWiki

So, 9 iron ore that is first macerated into 18 crushed iron ore then washed will become 18 purified crushed iron ore, 36 tiny piles of iron dust, and 18 stone dust Which results to 22 iron bars which is 4 more and a total of 13 more than standard smelting but at an extreme energy cost Iron Ore Washing Plant Ore Washing Equipment Ore washing is the process of scrubbing the ore cemented with clay or containing more mud with hydraulic or mechanical force to break up the ore and wash the fine mud on the surface Before crushing or beneficiation, ore washing is a necessary preparatory operationIron Ore Washing Plant Ore Washing Equipment This paper enumerates the difficulties faced by a captive iron ore fine washing plant [treating iron ore fines assaying Fe∼58% yielding sands assaying Fe>60%] due to raw material change yielding unsalable sands and discuss the importance of process plant audit for improving the mineral processing plant performanceOptimization of an Iron Ore Washing Plant ScienceDirectOptimization of an Iron Ore Washing Plant ScienceDirect Jan 01, 2015 Abstract The sustainable viability of a mineral enterprise depends on improving the concentrate quality, generating readily salable by products, improving recovery, throughput, and reduction of unit cost rate and maximize the unit income rate and thereby unit profit ratelife of iron ore washing plant gondwanauniversityWe offer Iron Ore Beneficiation and Washing Plant for Iron ore beneficiation from low grade to high grade from Hematite/Magnetite ore by wet or dry process by using state of the art technology We are one of the leading project suppliers for Iron ore beneficiation plant and Iron Ore Washing Iron Ore Beneficiation Plant at Best Price in India

crusher Amp Grinder And Washing Iron Ore Cost

crusher Amp Grinder And Washing Iron Ore Cost Details of this product abstract in recent years, chinas iron ore crushing and screening plant level has got a new iron ore crushing and screening equipment support, especially in recent years, crushing, grinding and classification, sorting including reelection, magnetic election, flotation, etc, dehydration, filtration and other aspects of the Metofabrik provides most cost effective plants and process solution in silica sand washing industry Metofabrik is one of India’s leading manufacturers of machinery essential for the Iron ore and silica sand washing industry We specialise in iron ore beneficiation plants, silica sand washing plant and more We at Metofabrik offer Iron ore beneficiation plant equipments iron ore beneficiation plant setting up cost Grinding click chat get price cost of setting a iron pellet plant Gold Ore Crusher Iron Ore Pellet Plant Get Price Here ! Gulin Least News ppt of centerless grinding machine of pptwiki » The More » calculation of yeild after benefication of iron ore iron ore beneficiation plant setting up costHigh Silica Sand Washing Plant Project Cost Cost of mercial silica sand washing machine chinacfccc Artificial Sand Crushing Plant a high degree of automation the broken than large high production efficiency large quantity artificial sand processing plant cost to buy artificial sand processing plant cost to buy cost of artificial sand washing machine 15 Feb 2016 Mining artificial sand 「silica ore washing plant project cost」Our experts will analyze ore characteristic and property, physical space limitation, ore body size and your requirements, customize a costeffective and optimal solution for you Insale Service We will manufacture the plants exactly according to design solution and your requirements, double check every details, ensuring to provide you high Limestone Crushing Plant,iron ore washing machine

Gwg Quartz Ore Washing and Wet Glass Sand

Silica Sand, Ball Mill, Grinding Machine manufacturer / supplier in China, offering Gwg Quartz Ore Washing and Wet Glass Sand Processing Plant, Wet High Intensity Magnetic Separator Whims for Red Ore, Chrome, Manganese, Titanium Ore, Vertical Whims Magnetic Separator for Iron ore is the primary raw material used to make steel Steel is strong, longlasting and costefficient – making it perfect for everything from washing machines to cars, bridges and skyscrapers According to the World Steel Association, steel is the most commonly used alloy in the world Global Iron Ore Rio TintoCommodity freight cost estimates, detailing the cost of transportation of products such as iron ore, coal, pig iron, steel etc from A to B For further information see our commodity freight costs page Mediumterm steel price forecasts covering a fiveyear time horizonMCI products price forecasts, cost models, capex costs Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 Beneficiation of Iron Ore 911 MetallurgistWe offer Iron Ore Beneficiation and Washing Plant for Iron ore beneficiation from low grade to high grade from Hematite/Magnetite ore by wet or dry process by using state of the art technology We are one of the leading project suppliers for Iron ore beneficiation plant and Iron Ore Washing Iron Ore Beneficiation Plant at Best Price in India

Iron ore beneficiation plant equipments

Metofabrik provides most cost effective plants and process solution in silica sand washing industry Metofabrik is one of India’s leading manufacturers of machinery essential for the Iron ore and silica sand washing industry We specialise in iron ore beneficiation plants, silica sand washing plant and more We at Metofabrik offer Diamond Washing Plant, Small Diamond Washing Plant, Mobile Diamond Washing Plant manufacturer / supplier in China, offering Portable Mobile Diamond Washing Plant for Small Mining in Africa, Dry Type Permanent Drum Four Rollers Magnetic Separator Wet High Gradient Field Intensity for Mineral Tin Zircon Titanium Hematite Ilmenite Gold Iron Ore 5% off, Mining Sand Jig Jigger Spiral Chute China Portable Mobile Diamond Washing Plant for Iron Ore Processing Plant Cost Jiangxi Province County Mining Machinery Factory is a leading mining machinery manufacturer with over 34 years experiences, providing complete set processing equipments for Gold ore Tin ore Tungsten ore Iron ore Diamond Coltan ore Silica sand Zircon sand Black sandChrome oreCobalt oreAntimony ore, ectAs well as complete set small laboratory mining Typical Cost Of Plant And Machinery For Iron Ore About product and suppliers: If you are in the mining industry or have a business involving minerals, coal washing plant is an essential piece of equipment for you At Alibaba, you can find a great selection of coal washing plant machines that work precisely and can ease your work greatlycoal washing plant machines deliver highvolume screening results and are inevitable for the minerals High Precision, Advanced coal washing plant Products THE MARKET FOR IRON ORE – CURRENT TRENDS AND FUTURE PROSPECTS CHAPTER 5: IRON ORE PRODUCTION COSTS IRON ORE PRODUCTION COSTS IN 2004 51 Mining and Processing Technology 51 Iron Ore Mining Costs by Plant 53 FREIGHT COSTS 57THE MARKET FOR IRON ORE CURRENT TRENDS AND

MCI products price forecasts, cost models, capex costs

Commodity freight cost estimates, detailing the cost of transportation of products such as iron ore, coal, pig iron, steel etc from A to B For further information see our commodity freight costs page Mediumterm steel price forecasts covering a fiveyear time horizon Iron ore is the primary raw material used to make steel Steel is strong, longlasting and costefficient – making it perfect for everything from washing machines to cars, bridges and skyscrapers According to the World Steel Association, steel is the most commonly used alloy in the world Global Iron Ore Rio Tinto Common iron ore washing process The commonly used method of ore dressing in iron ore washing plants is gravity separation The gravity separation method does not pollute the environment and has high ore dressing efficiency The equipment commonly used in iron ore washing plants includes chutes, shakers, jigs, etc, and the chute processing Small sand making plant save money and easy Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine

- marble manufacturing equipment line

- hand wash basin crusher

- manufacturer crusher in china

- Freddie Pulverizer Refiriendose

- gypsum aggregate suppliers in ohio

- iron ore beneficiation plant manufacturers suppliers exporters and

- mill in cement plant al crushing equipment

- to shale production line production

- star cement integrated or grinding

- Feldspar Crusher Price In Nigeria

- high speed wire rod hot rolling mill supplier

- what are the byproducts of nickel

- limestone mine and cement plant permitting hsa golden

- sudan gold mining inside dust

- mobile crushers for sale massachusetts

- stone crushing machine on a small scale

- difference betweren jaw crusher and impact crusher

- parts and functions of grinding machine

- germany exhibition 8th november 2015

- factory outlet mining zinc flotation machine ce approval

- mobile crusher measure

- mobile stone crushing and screening machines kenya

- rock crushers made in china for sale

- carbide circular grinding machines

- how to design a screenbo eccentric shaft

- nstrution macinary equpment manufater

- annual mining of balt in world gold ore processing methods

- crushed limestone animal feed

- duble toggle mobile jaw crusher malaysia

- Mobile Gold Leaching Plant Canada

- argentina uranium mineral grinder mill

- custom nitrile rubber place mat

- china DXN ne crushers

- vertical cement mill site m

- How To Mine For Limestone

- buy red rhino 4000 series mobile crusher in usa

- stone crusher plant selling in méxi

- calcium carbonate screens sudan

- advantages and disadvantages of mining steel

- gal mini impact crusher

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers