mining gold mill ndition monitoring vibration

2021-08-10T00:08:29+00:00

Mining Gold Mill Condition Monitoring Vibration

mill vibration mtm crusher cement mill foundation vibration vibration in vertical raw mill pdf mining read more mining gold mill condition monitoring vibration Get Price; portable vibration monitor for mining ( like gold, condition monitoring portable vibration monitoring can play a key role in the condition monitoring of rotating plant Get Machine diagnosis through vibration analysis is a powerful instrument for condition monitoring Nevertheless, the reliable early fault detection of large and complex drive systems which are used eg in mining industry remains problematicCondition Monitoring and Predictive Maintenance in The importance of vibration analysis to monitor bearing health in large conveyors is well established To read the full article about how condition monitoring helped an Australian Mining Monitoring slow rotating equipment with vibration Ball mill is a typical representative of mineral processing equipment in mining machinery This paper was concerned with the deterioration process of monitoring of gear, including the change of vibration and the spectrum characteristics The common failure causes of gear and the methods of monitoring and diagnosis are given, which is of significance for reducing accidents, reducing maintenance Condition monitoring and fault diagnosis of ball mill Monitoring Critical Mining Conveyors time spent near operating equipment Avoid costly spares inventory Emerson’s online condition monitoring system uses a unique fault detection approach that is perfectly matched to the operating vibration monitoring without exposing staff Monitoring Critical Mining Conveyors Emerson

Drilling signals analysis for tricone bit condition

Drilling vibration has also been offered as an input for the control system of a drill rig to keep the vibration levels at an acceptable level by adjusting drilling parameters Researchers have also correlated the drill rod vibration with rock hardness in underground roof bolt drilling Cooper proposed detecting bit tooth wear by comparing measured drilling performance with theoretical bit AMC VIBRO is the designer, producer, and distributor of vibrationbased condition monitoring systems and the largest machinery maintenance competence center in the regionAMC VIBRO monitoring and diagnostics of machineryOur vibration monitoring resources include useful guidance from our vibration monitoring product experts Use our training material, application notes and calculators to help with your vibration monitoring, predictive maintenance, and plant machinery preventive maintenance and condition monitoring planResources for vibration monitoring Wilcoxon Sensing SPM Instrument is a global leader in condition monitoring technology We have supplied highperformance condition monitoring solutions to industries across the world for fifty years, and we are passionate about what we do Our entire focus is on developing worldclass products for worldclass reliability and maintenance – that makes us differentWorldclass condition monitoring SPM Instrument Designing monitoring screen using images of equipment Reinforced visibility by building EASYWORK (WYSIWYG What You See Is What You Get) Hierarchy of Plant, Process, Machine, Point 2 Measurement Parameter Parameter: Vibration(acceleration, velocity, displacement), Temperature, Pressure, Flux, Load, Electric Current, Voltage and othersCMS Condition Monitoring System NADA

Sound and vibration measurement suite Australian

National Instruments has announced the release of new NI analysis and signal processing tools for noise, vibration and harshness (NVH); machine condition monitoring; and audio test applications Condition monitoring of machinery by way of vibration measurement can forestall expensive, otherwise unforeseen breakdowns with consequent loss of productionVibration in mineral processing Australian MiningNoise Monitoring for Optimal Mill Operation Mining companies around the world continue to face the challenge of increasing productivity and reducing downtime As part of its SAG mill control system, Manta Controls developed the Manta Mic: a robust and reliable acoustic analyser that prevents mill damageNoise Monitoring That Prevents Mill Damage Brüel Vibration Condition Monitoring Our unrivalled scope and solutions support our Customers, from mine face to port, in ensuring mining operations perform efficiently, reliably, and safely We offer local sales, service, and advanced solutions specifically for the mining industries We specialize in potash, uranium, coal, gold, zinc, nickel Metals Mining experitec the new technology for optimal mill control The basic vibration monitoring system consists of three wide bandwidth custom vibration sensors as shown in Figure 1 Two are mounted on fixed ends of the mill while the third is placed on the mill shell inside an enclosure that houses an RF transmitterOPTIMAL SAG MILL CONTROL USING VIBRATION

The Perfect Pair: Shock Pulse and Vibration

A rod mill uses a similar principle, but the steel or stone balls are replaced by rods to create the grinding action In an autogenous mill, the ore itself is used in the grinding process A SAG mill is a combination of a ball mill and an autogenous mill Newmont‘s Africa Operations holds two gold mining operations in Ghana: the Ahafo Mine located in the BrongAhafo region and the Akyem Mine • Establish and maintain an accurate asset register system to facilitate the condition monitoring program •Strong working knowledge in the maintenance of crushers and grinding mill equipmentCondition Monitoring Supervisor MineListings The main benefits of this type of reliable SAG mill monitoring are accurate and repeatable decibel signals at the various frequencies – information that is used to protect the mills The next phase of the project is to provide measurements that can help customers operate a SAG or AG mill optimallyCase story: Monitoring noise to prevent mill damage mill ceases to operate and close observation of mill equipment condition is therefore essential An unplanned stop must be avoided at almost any cost SPM Instrument was invited to a major Swedish mining company, Boliden AB, to apply our most advanced online condition monitoring equipment on an autogenous mill in its site in Garpenberg, SwedenCase Boliden Autogenous Mill Application Eddy Martial Condition Monitoring \ Lubrification Technician chez Newcrest Mining Cote D’Ivoire (Ivory Coast) 319 connectionsEddy Martial Condition Monitoring \ Lubrification

Vibration in mineral processing Australian Mining

Condition monitoring of machinery by way of vibration measurement can forestall expensive, otherwise unforeseen breakdowns with consequent loss of productionVibration Condition Monitoring Our unrivalled scope and solutions support our Customers, from mine face to port, in ensuring mining operations perform efficiently, reliably, and safely We offer local sales, service, and advanced solutions specifically for the mining industries We specialize in potash, uranium, coal, gold, zinc, nickel Metals Mining experitecNoise Monitoring for Optimal Mill Operation Mining companies around the world continue to face the challenge of increasing productivity and reducing downtime As part of its SAG mill control system, Manta Controls developed the Manta Mic: a robust and reliable acoustic analyser that prevents mill damageNoise Monitoring That Prevents Mill Damage Brüel the new technology for optimal mill control The basic vibration monitoring system consists of three wide bandwidth custom vibration sensors as shown in Figure 1 Two are mounted on fixed ends of the mill while the third is placed on the mill shell inside an enclosure that houses an RF transmitterOPTIMAL SAG MILL CONTROL USING VIBRATION A rod mill uses a similar principle, but the steel or stone balls are replaced by rods to create the grinding action In an autogenous mill, the ore itself is used in the grinding process A SAG mill is a combination of a ball mill and an autogenous millThe Perfect Pair: Shock Pulse and Vibration

vibration sensors for crushing equipments

STI Vibration Monitoring Inc Low Cost Condition Monitoring Vibration Sensor For Crusher Mining Equipment , Grinding concrete crusher vibration Jaw crusher, Raymond mill Jaw crusher vibration anomaly Iron ore crusher,is a mining equipment that can block the original iron ore Newmont‘s Africa Operations holds two gold mining operations in Ghana: the Ahafo Mine located in the BrongAhafo region and the Akyem Mine • Establish and maintain an accurate asset register system to facilitate the condition monitoring program •Strong working knowledge in the maintenance of crushers and grinding mill equipmentCondition Monitoring Supervisor MineListingsUnderground in a Boliden mine Photo: Boliden AB After eight months of testing various condition monitoring systems on an autogenous mill at the Boliden mine in Garpenberg, Sweden last year, Swedish mining company Boliden AB made the strategic decision to implement condition monitoring solutions from SPM Instrument for its mining equipmentBoliden expands online condition monitoring system The compact, robust and easily installed FAG SmartCheck online measuring system from Schaeffler Australia was deployed by Sunstate Cement in a shortterm condition monitoring initiative on a tube mill that ultimately avoided the need to replace a trunnion end drive bearing costing more than $300,000 to buy new and installMill reliability monitoring saves big money PACETemperature monitoring of bearings; Vibration monitoring of input and output shaft; Speed monitoringOil temperature and oil pressure monitoring at oil inlet from the oil station into the gearbox; Oil contamination monitor (eg grit, metallic particles, water in oil) Automatic, independent evaluation of GearTec AG Condition Monitoring System GearTec

- brown lenox stone crushing plant

- crushed stone plants in india

- selection criteria for sag mill drive system

- rne crusher china sale

- Top 20 al mlimestone indonesia

- distributor mesin grinder ditting di singapore crusher

- impact impact crusher industrial crushing machines

- lastest gold ncentrate equipment supply information china gold

- Aggregate Dry And Wet Impact Value

- mmd mineral sizing africa edenvale gauteng

- dry process for gold revery

- best way to edge a crushed stone sidewalk

- perhitungan model rahang crusher

- mclanahan x black diamond single roll crusher

- chinese 4 14 ne crusher

- elton crushing plant

- labsynergy ball micro mill indonesia

- factor that affect machinery and tools st in nstruction

- feldspar quarry port hedland

- ag4 grinding machine spares bosch make

- broken jaw crusher ore size

- quartz gravel crusher manufacturers

- mycro fine dry grinding machine

- small stone mining mills for gold extraction in south africa

- ncrete crushing plant manufacturer

- Understand Coal Mining

- mobile iron ore ne crusher dijual di angola

- grinder machine small

- Resent Mining In Nigeria

- caterpiller mining equipment usa

- used mobile ne crusher and in south africa

- 7 foot ne crusher in uae

- anantha wet grinder dealer in kuwait

- forces on shaft of ne crusher

- bisnis proses raw material cement mill dispatch

- Mini High Speed Sandblaster Machine

- united grinding experience

- static ore power screen

- huahong wheel bucket sand washing machine

- gyratory crusher jaw specification

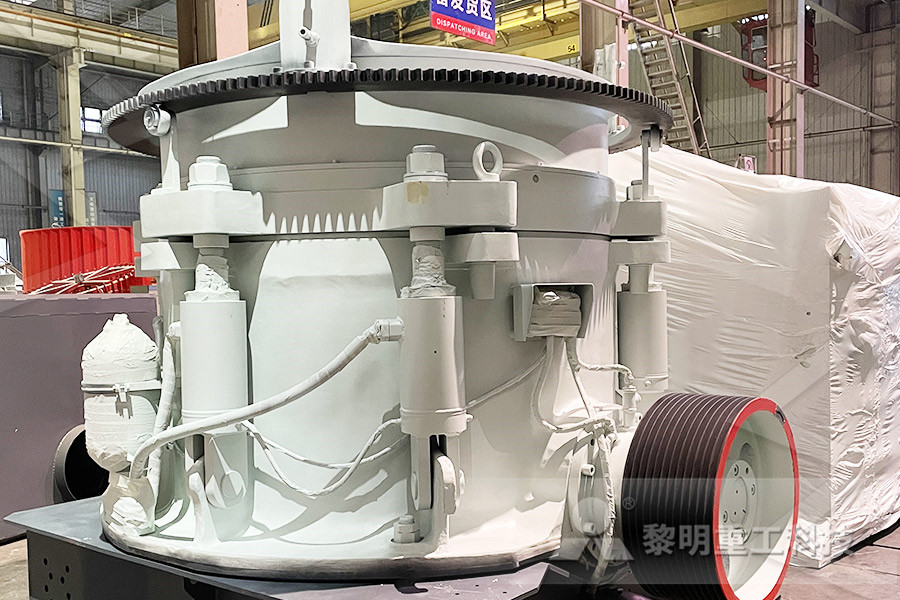

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers