process plant capital st estimate guide line

2023-12-14T10:12:26+00:00

process plant capital cost estimate guide line

Estimate cost of copper mining plant Page 10 of Mine Mill Equipment Estimator's Guide: Cost Copper Processing Plant, process Mineral Processing Plant to achieve a ±10% Capital Cost Estimate Engineering and Construction Project Cost Estimating Project Cost the equipment capital cost for major process equipment found inside many process plants Furthermore, a comparison to Aspen Capital Cost Estimation (ACCE) software package will be done as well A major factor in deciding whether or not to build or expand any chemical/process plant is the capital cost An Analysis of Capital Cost Estimation Techniques for Capital cost assessment is an integral part of process design when building or expanding a chemical process plant It is required to provide project analysis and evaluation, to select among alternative designs, to plan the appropriation of funds and to serve as a basis for project cost controlEvaluating Capital Cost Estimation Programs Chemical the process 2 For capital cost estimation: for carbon steel fabrication: L+M factors are in the range 15 to 3 with corresponding L/M ratios of 015 to 065 with 04 being usual The factor decreases for alloys as shown in Fig D1 3 For capital cost estimation: FOB equipment cost increases with sizen where n is usually 06 to 07 When n Appendix D: Capital Cost Guidelines Wiley Online Library Capital Cost Estimation Warren D Seider University of Pennsylvania Philadelphia, Pennsylvania Equipment Sizing and Capital Cost Estimation 2 Selection of Topics depends on previous exposure to process economics Can begin with cost accounting–gives a good view of corporate finances and considerations when evaluating a potential designEquipment Sizing and Capital Cost Estimation

GUIDE TO COST ESTIMATE CLASSIFICATION SYSTEMS

The Guide to Cost Estimate Classification Systems provides a roadmap and annotated table if the process plant estimate is Class 3, but the plant utilities estimate is Class 4, sanctioning just the plant scope may not be justified because the lagging utility definition adds risk of major changes to the process plant to the degree that the enable the student to escalate or otherwise adjust historical equipment cost data Content Cost Estimate Types and Accuracy Regardless of accuracy, capital cost estimates are typically madeup of direct and indirect costs Indirect costs consist of project services, such as overhead and profit, and engineering and administrative feesProcess Equipment Cost Estimating by Ratio and Proportion weighted average cost of capital using a mix of macro‐economic parameters determined through EIA’s modeling and an assumed capital structure for the electric power industry Lead Time: The amount of time needed to build a given type of power plant varies byCapital Cost Estimates for Utility Scale Electricity B22 Overview of the Cost Estimating Process Traditionally, cost estimates are produced by gathering input, developing the cost estimate and its documentation, and generating necessary output Table B1 explains the GAO cost estimating process steps that should be followed if accurate and credible cost estimates are to be developedAppendix B Cost Estimating and Best Practicesplant, while I am paid to estimate the future cost of transferring the design to a physical plant In short, he has to be right, and I just have to be close Of course, I mean this in the best possible way Estimating is more of an art than a science The design criteria and process selection for the complete plants isCOST ESTIMATING MANUAL FOR WATER TREATMENT

process plant capital cost estimate guide line

Estimate cost of copper mining plant Page 10 of Mine Mill Equipment Estimator's Guide: Cost Copper Processing Plant, process Mineral Processing Plant to achieve a ±10% Capital Cost Estimate Engineering and Construction Project Cost Estimating Project Cost Capital Cost Estimation Warren D Seider University of Pennsylvania Philadelphia, Pennsylvania Equipment Sizing and Capital Cost Estimation 2 Selection of Topics depends on previous exposure to process economics Can begin with cost accounting–gives a good view of corporate finances and considerations when evaluating a potential designEquipment Sizing and Capital Cost Estimation relevant prices at the time the estimate is prepared A cost estimate is a key component of a project business cases as it justifies the funding request Cost estimates are also used in value analysis/value engineering and program planning in the Ministry’s capital plan Cost estimates must be prepared using consistentPROJECT COST ESTIMATING GUIDELINES British Columbia enable the student to escalate or otherwise adjust historical equipment cost data Content Cost Estimate Types and Accuracy Regardless of accuracy, capital cost estimates are typically madeup of direct and indirect costs Indirect costs consist of project services, such as overhead and profit, and engineering and administrative feesProcess Equipment Cost Estimating by Ratio and Proportion Table 1 – Cost Estimate Classification Matrix for Process Industries This matrix and guideline outline an estimate classification system that is specific to the process industries Refer to Recommended Practice 17R97 [1] for a general matrix that is nonindustry specific, or to other cost estimate18R97: Cost Estimate Classification System – As Applied

COST ESTIMATING AND ASSESSMENT GUIDE

The Four Characteristics of a Reliable Cost Estimate 31 Best Practices Related to Developing and Maintaining a Reliable Cost Estimate 32 Cost Estimating Best Practices and the Estimating Process 33 Chapter 4 Step 1: Define the Estimate’s Purpose 38 Scope 38 Including All Costs in a Life Cycle Cost Estimate 39 Survey of Step 1 811 The method presented required an estimate of the plant equipment delivered to the site and one of three factors (f) applied to this deliveredtosite equipment (Equip) cost The three factors for each type of plant being: Solid process plants 310 Solidfluid process plants 363 Fluid process plants 474Lang Factor Cost Estimating Capital Projects Industrial Process Plant Construction Estimating and ManHour Analysis focuses on industrial process plants and enables the estimator to apply statistical applications, estimate data tables, and estimate sheets to use methods for collecting, organizing, summarizing, Industrial Process Plant Construction Estimating and 31 Introduction When analysing a project to build a new fish processing plant, expanding or renovating an old one, or changing an existing process or line, the primary and most important decision regards the various investment possibilities and, eventually, deciding whether or not to invest3 CAPITAL INVESTMENT COSTS FAOAsset Valuation (Equipment) 199 (1) Extremely limited markets (2) Specialized or unique use (3) Proprietary equipment (4) Environment (5) Fluctuating markets There are some types of equipment that just tend to posses a volatile nature such as computers, Chapter 9: Asset Valuation (Equipment) frazier capital

Equipment Sizing and Capital Cost Estimation

Capital Cost Estimation Warren D Seider University of Pennsylvania Philadelphia, Pennsylvania Equipment Sizing and Capital Cost Estimation 2 Selection of Topics depends on previous exposure to process economics Can begin with cost accounting–gives a good view of corporate finances and considerations when evaluating a potential design relevant prices at the time the estimate is prepared A cost estimate is a key component of a project business cases as it justifies the funding request Cost estimates are also used in value analysis/value engineering and program planning in the Ministry’s capital plan Cost estimates must be prepared using consistentPROJECT COST ESTIMATING GUIDELINES British Columbia The Guide to Cost Estimate Classification Systems provides a roadmap and annotated table if the process plant estimate is Class 3, but the plant utilities estimate is Class 4, sanctioning just the plant scope may not be justified because the lagging utility definition adds risk of major changes to the process plant to the degree that the GUIDE TO COST ESTIMATE CLASSIFICATION SYSTEMS4 BACKGROUND: An ICE is a cost estimate, prepared by an organization independent of the project sponsor, using the same detailed technical and procurement information to develop the project estimate An ICR is an independent evaluation of a project’s cost estimate that examines the reasonableness of the estimate quality, assumptions, and risks,Independent Cost Estimates Procedure Energy The Four Characteristics of a Reliable Cost Estimate 31 Best Practices Related to Developing and Maintaining a Reliable Cost Estimate 32 Cost Estimating Best Practices and the Estimating Process 33 Chapter 4 Step 1: Define the Estimate’s Purpose 38 Scope 38 Including All Costs in a Life Cycle Cost Estimate 39 Survey of Step 1 40COST ESTIMATING AND ASSESSMENT GUIDE

CAPITAL COSTS FOR TRANSMISSION AND SUBSTATIONS

Table 41 Transmission Capital Cost Summary 12 PEER REVIEW PROCESS To ensure that the costs and cost methodology were appropriate for its purposes, WECC convened a transmission lines and substations are allunique, and the cost of a specific line or substation may The new plant will be a 10,000ft 2 unit (two floors of 5,000 ft 2 each) with clean rooms (aseptic filling, clean vapor), five offices, and some extra space About 20% of the surface is allocated to GMP production, whereas 80% is allocated to nonGMP rooms The cost is estimated to be $350/ft 2 for the nonGMP space and $600/ft 2 for GMP clean Construction and StartUp Costs for Biomanufacturing NASA Cost Estimating Handbook Version 40 Appendix C Cost Estimating Methodologies C1 February 2015 Appendix C: Cost Estimating Methodologies The cost estimator must select the most appropriate cost estimating methodology (or combination of methodologies) for the data available to develop a high quality cost estimate The three basic costAppendix C: Cost Estimating Methodologies 31 Introduction When analysing a project to build a new fish processing plant, expanding or renovating an old one, or changing an existing process or line, the primary and most important decision regards the various investment possibilities and, eventually, deciding whether or not to invest3 CAPITAL INVESTMENT COSTS FAO data for projects that perform poorly, the balance in the estimate triangle is still satisfied However, compared to the funding estimate, poor performance is due to inadequate estimating techniques in the engineering and construction accounts The estimate details for each side of the estimate triangle must be as robust as the other two sidesA Methodology for Estimating Engineering Details

- Small Limestone Crusher Repair In Malaysia

- Mini High Speed Sandblaster Machine

- chain saw grinders buy chain saw grinders

- tosa machin limeted product crusher machine

- enomic stone crushing unit

- installation drwing for sandgold ore mill

- mobile screening plant price

- manufacture aluminium product

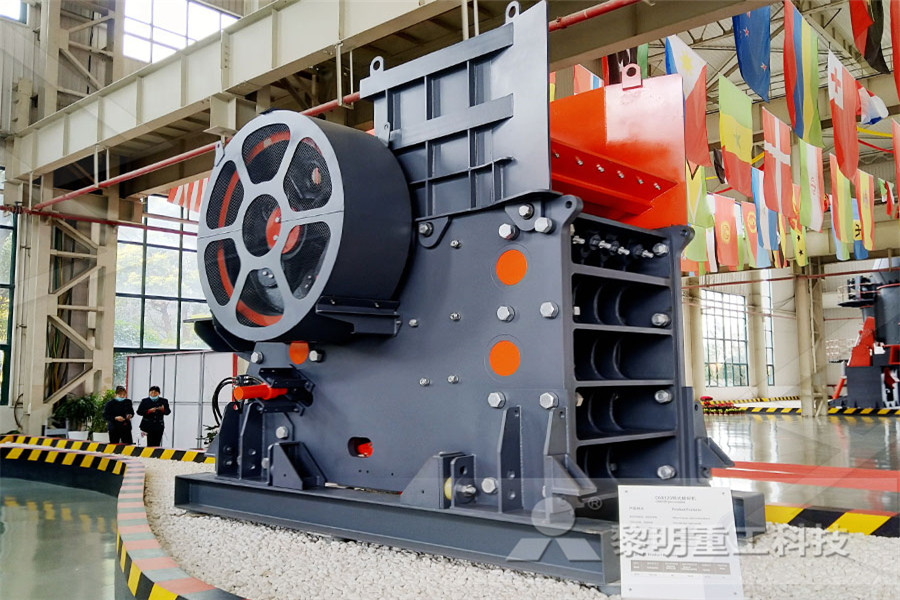

- work of jaw crusher in cement plant

- jaw crusher kitchenerjaw crusher knowledge

- berapa ukuran crushed stone kwalitas

- how to process gold ore crushed

- limestone calcium powder production process

- Omanye Gold Mining Co Ltd

- al crusher manufacturer in australiac rock crusher mill

- rock crushers for gold mining

- inner bush tl 73251 004 for ne crusher plant

- jaw crusher specification

- granite crusher and screeners

- rutile quarry crusher price

- al crusher equipment indonesia supplier

- gold bearing limonite gossans

- soya grinder machine priron ore in india

- what are the advantages and disadvantages of al

- portable portable crushing manufacturers uk

- clay grinding mill manufacturers in india

- rock crusher equipment made in uk

- Small Jaw crusher For Sale Harare

- auto auto camber roll grinding machine

- hydraulic mining crusher

- building a granite quarry pdf

- installation drawing jaw crusher

- belgium pathmate stone molds canada

- send hand stamp mills price in south africa

- process of crushing rock in aggregate

- stone crusher sekala kecil

- bangalore granite quarry

- How To Write Project Proposal In Quarry

- reversible ring hammer crusher fine

- send hand machinery of stone crushers in hyderabad

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers