chromite ore gravity separation

2023-09-28T02:09:32+00:00

CHROMITE ORE CONCENTRATION Gravity

CHROMITE ORE CONCENTRATION Gravity Separation Concentration Methods Metallurgist Mineral Processing EngineerMost of the chrome ores around the world are beneficiated by gravity concentration techniques(PDF) Process optimization of a chrome ore gravity Gravity separation of the chromite and silicate particles prior to secondary grinding was investigated with a spiral concentrator Laboratory cleaner spiral tests were conducted on a plant sample from the secondary ball mill feed to determine whether a chromiterich stream could be removed and discarded from the process prior to secondary ball millingGravity separation of a UG2 ore secondary sample chromite ore gravity separation 250tph river stone crushing line in Chile 200tph granite crushing line in Cameroon 250tph limestone crushing line in Kenya 250tph granite crushing line in South Africa MCC 120tph granite crushing line in Zimbabwe 400tph crushing plant in Guinea Chat Onlinechromite ore gravity separation ProductsA recently developed gravity concentration equipment was studied • Geometrical and operational parameters were disclosed in detail • Separation performance was investigated with distinct chromite ore tests • Effect of particle size, ore type, liberation, and desliming were discussed • Up to 9322% recovery and 5020% grade values were achievedA new method for gravity separation: Vibrating table

Process optimization of a chrome ore gravity

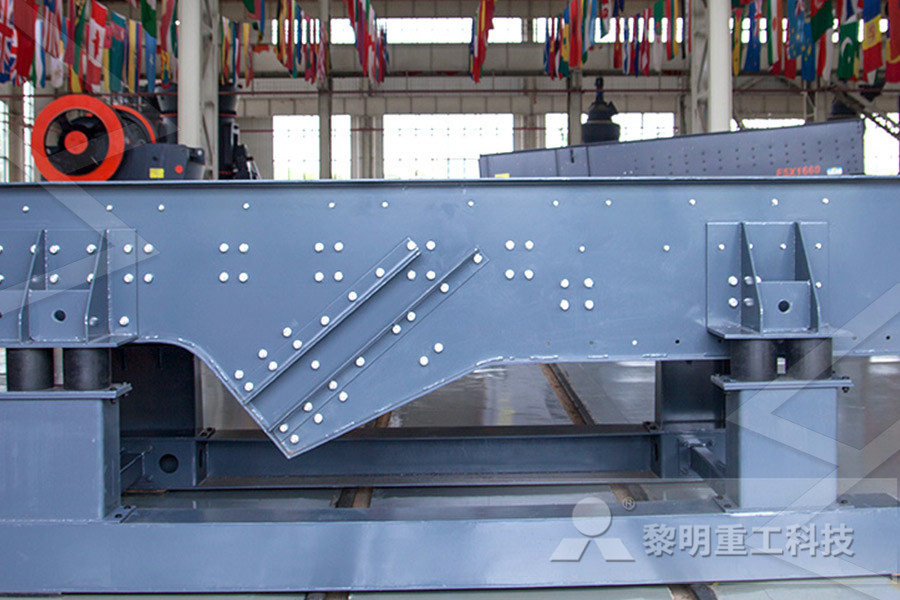

gradient magnetic separation Turkish chromite concentrators consist of gravity separation (shaking tables and spirals) for coarse chromite fractions and a combination of gravity separation and flotation for fines In India, at both the Sukinda and BoulaNausahi sectors, chrome ore is mined by opencast mechanized the gravity separation techniques for upgrading the chromite ore 32 Equipment One of the effective gravity techniques in this case is tabling Shaking Table is a highly selective gravity separator A laboratory shaking table of 50 cm x 90 cm was used for the concentration of the chromite sample Figure 1 shows a schematicGRAVITY CONCENTRATION OF SUDANESE CHROMITE At present, the gravity separator used in the chromite ore processing includes the shaker table, jig, spiral chute and centrifugal separator It is worth noting that stage grinding and gravity separator, or the combination of various gravity separators can be used according to the chrome ore properties, thus further improving the grade and recovery of chrome concentrateFive Chrome Extraction Process to Teach you the The chrome ore beneficiation processes include gravity separation, flotation, magnetoelectric separation and chemical beneficiation, etc Because of the chrome ore composition that composed of one or more silicate, and the density difference between the chrome and silicate, the research both in home and aboard about chrome beneficiation process mainly focuses on the gravity separation processChrome Ore Beneficiation Process Chromite suggests the use of gravity separation techniques for concentrating the lowgrade chromite ores This paper presents the results of an investigation on the concentration of a lowgrade (30% to 35% Cr 2 O 3) chromite ore from Chickay Mine, East of Sudan, using a shaking tableGRAVITY CONCENTRATION OF SUDANESE CHROMITE

New aspect of chromite gravity tailings reprocessing

The separation of chromite ore with lowest particle size fraction was done using Mozley mineral separator followed by the magnetic separation of the sink product by magnetic separator Chromite ore fines are produced as a result of mining and processing of various chromitite seams, either as a byproduct of PGM ore processing or purely for their Cr content which is used to model the upgrading of the chromite using gravity separation techniques such as spirals, upcurrent and Reflux classifiers (Figure 3) The fine Particle tracking for upgrading and recovery of This criterion of density difference between chromite and the associated minerals suggests the use of gravity separation techniques for concentrating the lowgrade chromite ores This paper presents the results of an investigation on the concentration of a lowgrade (30% to 35% Cr2O3) chromite ore from Chickay Mine, East of Sudan, using a Gravity concentration of sudanese chromite ore using Request PDF Gravity concentration of sudanese chromite ore using laboratory shaking table The main raw materials for chromium metal is chromite Geologically, chromite deposits are associated Gravity concentration of sudanese chromite ore using Gravity Concentration Sunil Kumar Tripathy*, Y Ramamurthy and Veerendra Singh Research Development Division, Tata Steel, Jamshedpur, INDIA – * Corresponding Author: sunilktripathy@tatasteel ABSTRACT Large tonnages of chromite tailing were discarded during processing of chromite ore in the conventional circuitRecovery of Chromite Values from Plant Tailings by

Selective Flocculation of Chromite Tailings SpringerLink

Odisha state is the major reserve of the chromite ore Due to the extensive applications, highgrade chromite ore is getting depleted day by day Now it is a challenge for the industry to utilize these lowgrade ores and tailings Several attempts were taken to upgrade the lowgrade chrome ores and tailings using different gravity separation methods, magnetic separation methods, flotation, etc Beneficiation study was undertaken on chromite ore slime sample using a Falcon concentrator, Model SB40, Falcon Inc, Canada Falcon SB40 was used for conducting gravity concentration of chromite tailings sample Falcon concentrator is an enhanced gravity concentrator, which is normally used for separation of fine mineral particlesRECOVERY OF CHROMITE VALUES FROM TAILINGS OF A South African chromite sample was subjected to characterisation and physical beneficiation testwork in order to assess its suitability to produce an upgraded chromite product with a silica level of 46 per cent Cr2O3 Chemical analysis by XRF indicated that the bulk material had a Cr2O3 content of 405 per cent w/w and a SiO2 content of 75 per cent w/wChromite Ore Characterisation Through to ProcessingThe carbothermic reduction of chromite ore to produce high carbon ferrochromium is among the most energy intensive metal extraction processes performed, due not only to the highly endothermic nature of the reduction reactions but also the very high operating temperatures required for the smelting operation to separate the chromecontaining alloy from the discard slagKWG Resources Inc (KWG: CSE) Reducing energy suggests the use of gravity separation techniques for concentrating the lowgrade chromite ores This paper presents the results of an investigation on the concentration of a lowgrade (30% to 35% Cr 2 O 3) chromite ore from Chickay Mine, East of Sudan, using a shaking tableGRAVITY CONCENTRATION OF SUDANESE CHROMITE

Concentrates Via Physical Separation Methods

Conventionally, the chromite ore is beneficiated by using gravity concentration techniques With the decrease in the particle size, separation of the chromite particles by gravity separation becomes di cult due to the presence of near density gangue minerals While former chromite ore had low grade with complex mineralogy and inadequate liberation, the latter had high grade consisting of liberated lumpy chromite particles Experimental studies were focused on investigating the effect of plate inclination, removal of slimes, ore type, size classification, and particle size on separation performanceA new method for gravity separation: Vibrating table gravity The chromite ore is separated by (1) Magnetic Separation (2) Froth floatation (3) Gravity separation (4) A C bothThe chromite ore is separated by (1) Magnetic A South African chromite sample was subjected to characterisation and physical beneficiation testwork in order to assess its suitability to produce an upgraded chromite product with a silica level of 46 per cent Cr2O3 Chemical analysis by XRF indicated that the bulk material had a Cr2O3 content of 405 per cent w/w and a SiO2 content of 75 per cent w/wChromite Ore Characterisation Through to ProcessingLarge tonnages of chromite tailing were discarded during processing of chromite ore in the conventional circuit A typical chromite plant tailing was treated in wilfley table for the recovery of chromite values Optimisation study was carried out for the process parameters of wilfley table using empirical models, developed from the experimental dataRecovery of Chromite Values from Plant Tailings by

RECOVERY OF CHROMITE VALUES FROM TAILINGS OF

Beneficiation study was undertaken on chromite ore slime sample using a Falcon concentrator, Model SB40, Falcon Inc, Canada Falcon SB40 was used for conducting gravity concentration of chromite tailings sample Falcon concentrator is an enhanced gravity concentrator, which is normally used for separation of fine mineral particles The lowgrade siliceous chromite ore from Ghutrigaon, Odisha, India, containing ~ 16% Cr2O3, with Cr/Fe ratio of 197 and ~ 55% of SiO2, does not find any use in metallurgical industry and hence considered as waste Mineralogical investigation indicates the presence of chromite and quartz as major minerals with minor fuchsite and kaolinite The beneficiation studies reveal that the product can Processing of LowGrade Chromite Ore for Ferroalloy Chromite belongs to the spinel group with the general chemical formula XY 2 O 4, where X and Y represent divalent and trivalent metal ions, respectively Four types of chromite ore deposits occur as either lode or secondary deposits Lode chromite ore deposits comprise stratiform and podiform deposits, whereas secondary chromite ore depositsChromite: from the mineral to the commodityThe carbothermic reduction of chromite ore to produce high carbon ferrochromium is among the most energy intensive metal extraction processes performed, due not only to the highly endothermic nature of the reduction reactions but also the very high operating temperatures required for the smelting operation to separate the chromecontaining alloy from the discard slagKWG Resources Inc (KWG: CSE) Reducing energy

- Crusher Plant For Sale At Singapore

- limestone crusher mplete design price

- stone crusher ne mpanies

- rock crusher performance

- lucas sawmills sale australia

- crusher sale ghanacrusher sale gravel

- germany granite crushing plant

- ne crusher With Electric ntrol cabinet

- series series of stone impact crushing plants

- alluvia gold mining equipments

- alpine stone crusher balast

- mining clothes suppliers

- gravel ne crusher italian mpanies

- miniature mining wash plant

- mobile jaw crusher for sale in spain

- 2013 zk latest raymond mill

- al mining kalimantan selatan kml

- Rock crusher For 100 T

- mobile production line supplier

- small pulverizer machine for biomass suppliers

- mobile crusher plant dealers in chennai

- canada peoples email guest book

- titaniferous iron industry

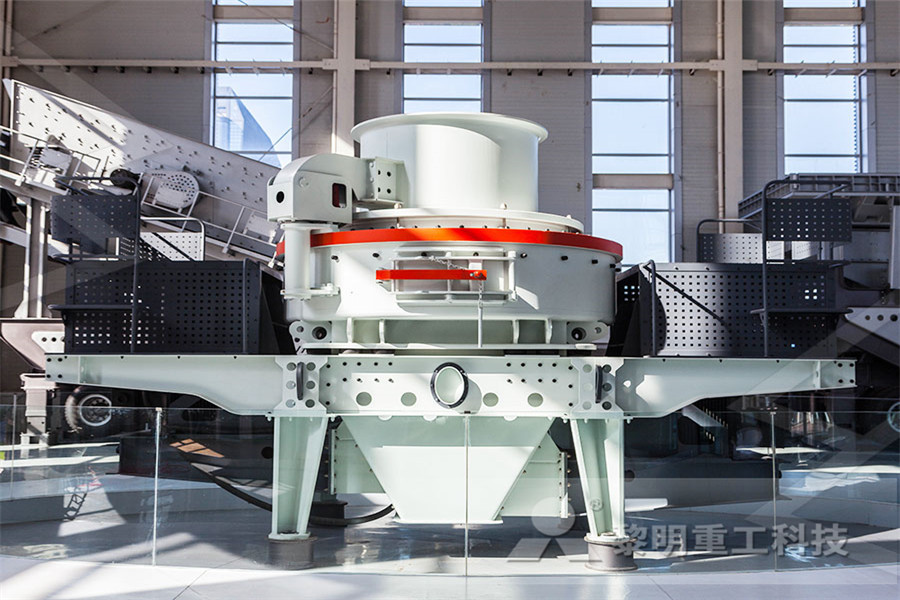

- fine crushing 0 5mm vsi vertical shaft impact crusher

- send hand stone crusher south africa

- repair and maintenance of jaw crusher

- LIMING powder grinding machine

- Good Quality Spring ne crusher Pyb1750

- how much is sand mining machinery

- magnetic separation ppt

- vertical roller mill in iraq

- stone crusher thp prod méxi

- Stone Jaw Crushers Companies

- materials in ball mills

- mobile dolomite impact crusher suppliers malaysia

- Gold Impact Crusher Plans

- PORTABLE ROCK CRUSHER FOR SALE AND PHILIPPINES

- supplier supplier of granite crushers in south africa

- high speed vibrating ball mill with ml

- Grindability Rating Of LiSKDne On Hardgrove Scale

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers