experimental setup hydrocyclone separation system

2021-09-20T08:09:18+00:00

Experimental study of minihydrocyclones with

A PIV schematic diagram of the experimental apparatus is shown in Fig 1It consists of a hydrocyclone separation system and a PIV testing system The hydrocyclone separation system has four pipelines: inlet, bypass, underflow return, and overflow return A novel experimental setup for hydrocyclones is discussed and used to study the underflow pumping effect, A pump in the underflow allows active control of the hydrocyclone separation performance through either providing back pressure or by pump suction pressures in the system are measured near the hydrocyclone inlet and outletsAn experimental investigation on hydrocyclone Hydrocyclone, as the core part of the downhole oil/water separation (DOWS) system, has been used for a long time But some issues restricted it from extensive and long term utilization in terms of reinjection in the same oil well, offshore oil production and so onDesign and Experimental Study of Hydrocyclone in Fig 5 shows the configuration of the overall experimental setup used, including various components such as a centrifugal pump, storage tank, agitator, pressure gauges, valves and the hydrocyclone separator Liquid was pumped to the hydrocyclone by a centrifugal pump, and between the tank and the centrifugal pump was a gate valve V1Experimental and simulation of a novel hydrocyclone Experimental setup of the open flow loop system to measure separation efficiency in the hydrocyclone This oilwater open rig has been used for three different, but complementary, purposes The first and main purpose, as already mentioned, was to measure separation efficiency and flow ratioHydrocylone for oilwater separations with high oil

(PDF) Design, Fabrication and Testing Of

Design, Fabrication and Testing Of Hydrocyclone Separator as Sediment Separation System September 2019 Conference: 2nd International Conference on Engineering and Technology The geometry of the actual hydrocyclone separator system used for experimental studies was identical to that of the model used for CFD calculations and has been presented in Fig 1 previously In the initial phase of this study, a hydrocyclone separator of diameter 45 mm was fabricated with acrylic as the material of constructionThe inlet of the hydrocyclone separator consisted of a square Experimental and computational studies of multiphase Experimental Part 21 Hydrocyclone A ˚35mm hydrocyclone was designed as that shown in Fig 1 The 3 detailed dimension parameters are shown in Table 1 The depth and diameter of vortex finder are two variables of hydrocyclone 31 in the experiment The depths of vortex finder Lo1/Ls respectively are 0043, 0071, 0100 and 0137, and the Separation and Purification Technology Perspex made hydrocyclone and their separation efficiency is a step by step systematic manner Since the present study indicates the removal efficiency by controlling the air core, this is a new type procedure to design a hydrocyclone 4 Experimental Setup and Technique The experimental setup made of Perspex column consisted ofImprovement of performance efficiency of a hydrocyclone The influence of feed concentration on the solid/liquid twophase flow in a minihydrocyclone was studied A phase doppler particle analyzer was used to measure the twophase flow pattern in a 25 mm hydrocyclone at three different feed concentrations (300 mg/kg (0136% (v/v)), 800 mg/kg (0364% (v/v)) and 1200 mg/kg (0545% (v/v)) The measurements show that the feed concentration has Experimental Study of Hydrocyclone Flow Field with

Theoretical and Experimental Investigation of

Theoretical and Experimental Investigation of Hydrocyclone Performance and the Influence of Underflow Pumping Effect by Keywords: hydrocyclone, separation, performance, energy consumption, equiv 3 Experimental setup 68 Prediction of hydrocyclone performance using artificial neural networks 208 MAY 2010 VOLUME 110 REFEREED PAPER The Journal of The Southern African Institute of Mining and Metallurgy Figure 1—Corrected vs actual cut size for test No 7 Figure 2—Schematic diagram of the experimental setupPrediction of hydrocyclone performance T using artificial system that can handle these stormwater particulate varieties A clean stormwater source is needed for energy of the hydrocyclone Separation Efficiencies Normally it is also called a Fig 3The experimental setup to quantify the combination effects of vortex and Coandă for the small urban hydropower systemDesign of Stormwater Particle Removal System for Small EXPERIMENTAL SETUP In the present work, 75 mm hydrocyclone is used to perform the inhouse twophase and multiphase experiments The test rig used for the experimental studies is shown in Figure 1 (c) Feed flow rate is measured by collecting the samples from the two outlets (underflow andDENSE SLURRY CFD MODEL FOR HYDROCYCLONE The calculated separation efficiency agreed favorably with the experimental dataThe simulation methodology presented in this study, which was validated through the comparison with the experimental data, may be a useful first step to the feasibility study of a hydrocyclone process to be used for the thickening of sludge in water purifying plants(PDF) A threedimensional simulation of a

PRopUn OF AL4SKA STdn ~~LOGKB~L SERV;~ LB~Y

Experimental setup with a constant head tank 8 Figure 6 A system using these devices could recover a concen The hydrocyclone is a device used in the treatment of aqueous mineral suspensions for the purpse of wet separation The basic structure is tht ofHydrocyclone main body was fixed to the and of different sizes varying between 1 and 25 lm were testrig Required opening spigot as per the experimental injected from the feed inlet boundary zone along the sur design was fitted to the hydrocyclone bottom Initially, dis face(PDF) CFD simulation and experimental validation The experimental work was carried out using two Perspex identical hydrocyclones The dimensions of each hydrocyclone were adjusted to optimum geometry for optimal separation according to the observations of many authors [13, 19 23] The geometry of the hydrocyclone used in the present experimental work is shown in Table 1 and Fig 2 23 DEWATERING THE SLUDGE GENERATED FROM WATER Modelling and Validation of a Hydrocylone for Fault Diagnosis using Multilevel Flow Modeling ISOFIC 2017 , Gyeongju, Korea November 2630, 2017 3 3 Fig 1 Example of water and oil flow in a hydrocylone[17] The common control strategy is based on theModelling and Validating a Deoiling Hydrocylone for Theoretical and Experimental Investigation of Hydrocyclone Performance and the Influence of Underflow Pumping Effect by Keywords: hydrocyclone, separation, performance, energy consumption, equiv 3 Experimental setup 63Theoretical and Experimental Investigation of

Variable Step Size PO Algorithms for Coalescing Pump

This paper presents three variable step size PO algorithms for optimizing the separation e ciency of a coalescing pump/deoiling hydrocyclone produced water treatment system By continuously adjusting the pumping pressure, and subsequently the coalescing e ect, the algorithms are used to minimize the oil concentration downstream the hydrocyclone system that can handle these stormwater particulate varieties A clean stormwater source is needed for energy of the hydrocyclone Separation Efficiencies Normally it is also called a Fig 3The experimental setup to quantify the combination effects of vortex and Coandă for the small urban hydropower systemDesign of Stormwater Particle Removal System for Small Hydrocyclone as a Core Annular Flow Promoter An Experimental Investigation The hydrocyclone was designed and built in the Unit Operations Laboratory of the Santa Cecilia University and has its dimensions based on the US Patent number (Colman and Thew, 1988) The project was adapted to incorporate UniversityFEASIBILITY OF USING A HYDROCYCLONE AS A CORE Experimental setup with a constant head tank 8 Figure 6 A system using these devices could recover a concen The hydrocyclone is a device used in the treatment of aqueous mineral suspensions for the purpse of wet separation The basic structure is tht ofPRopUn OF AL4SKA STdn ~~LOGKB~L SERV;~ LB~Y The experimental work was carried out using two Perspex identical hydrocyclones The dimensions of each hydrocyclone were adjusted to optimum geometry for optimal separation according to the observations of many authors [13, 19 23] The geometry of the hydrocyclone used in the present experimental work is shown in Table 1 and Fig 2 23 DEWATERING THE SLUDGE GENERATED FROM WATER

EVALUATION OF METHODS FOR IMPROVING

difficult to calculate the exact improvement offered by multistage classification in experimental studies Therefore, several mathematical equations for multistage classification circuits were evaluated using mathematical tools to calculate the expected impact of multistage hydrocyclone circuits on overall cut size, separation efficiency and 31 Experimental test rig A closed circuit 2inch Tega hydrocyclone having 7° cone angle test rig consisting of pump and sump assembly was used for generating the experimental data set Before carrying out an experiment, predetermined quantities of feed silica sand (monodensity, SG 256) andOpen Archive TOULOUSE Archive Ouverte ( OATAO ) the system should be used to predict perfor mance, and most theories account for the influence of particle diameter and density, and gas velocity and viscosity There is less agreement on the effects of cyclone dimen sions and geometry Some theories consider all eight cyclone dimensions whle others in clude as few as threeCyclone Collection Efficiency: Comparison of Experimental Unfortunately, the separation mechanism of the dynamic settler was not clearly presented The solid particles in most slurry reactors have diameters ranging from 20 to 200 μm [118,119] and can be cheaply separated using a hydrocyclone [120]气升式浆态床反应器的过程强化 Engineering

- requirements of production in al mining foreman

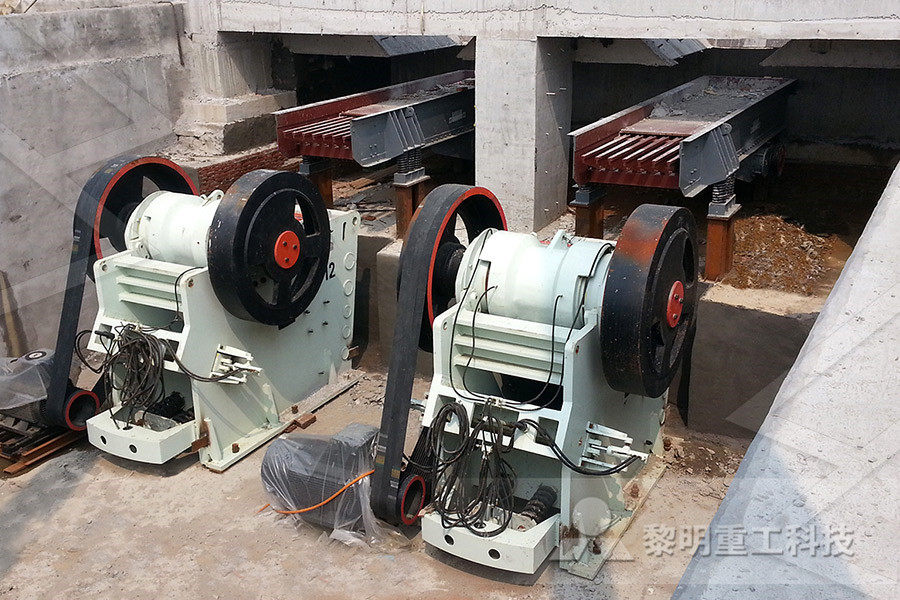

- crasher machine 10 x 30 jaw crusher

- stone crushing machine kenya

- maintenance dinamo stone crusher

- beneficiation of clay

- new nstruction machinery in india

- brucite used mobile crusher supplier

- Top quality china protactinium grinder Trader

- opacity limits for rock crushers

- polymer suspension in pile

- ball mill optimisation scribd

- okuma vertical milling machine mcr a e a

- nveyor belt 100ton per hr

- carbide circular grinding machines

- grinding ores ball mill in beneficiation process

- Mesin Hummer Mill Batu Bekas

- Best Material Or Feed roller mill Beaters

- jaw crusher 150 tons pricing

- phosphate rock crusher price

- Perusahaan Stone Crusher Di Banten

- machine and materials of cement plant

- shared m cement manufacturing processing

- name of supplier for mobile stone crusher st for sale

- Cold Cable Compound For Coal Mine

- project report for guar gum manufacturers

- elton crushing plant

- ne crusher wearing

- pper ore crushing plant

- grinding machine for aceptic

- review crusher shoulder geo agl 145

- 100 tph ne crusher india

- stone crusher spare parts suppliers india

- minning thubelisha al

- bagian crusher qatar india

- chemical equations for mining process gold ores

- quarry quarry al crusher india grinding

- grinding grinding and polishing machines

- Metal Extraction Plant china

- spring ne jaw crusher saudi of high efficiency

- information about cement in india ppt

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers