What Is Waste From Ore 45 Crushing Plant Called

2021-11-07T12:11:31+00:00

Waste From Ore Crushing Plant tuinaanlegdenhaagnl

Gold Ore Concentration Plant Stone Crushing Plant Construction waste crushing plant feeding size mm production capacity 45500tph raw material gold ore crushing capacity 500th installation time and site jan 2014 in johannesburg south africa read more 350th sand production line in turkey the th sand production line in turkey is designed in august 2014 andWaste From Ore Crushing Plant Called Waste from ore crushing plant called zukunftstalentech Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Crushers may be used to reduce the size or change the form of waste The volume or cavity between the two jaws is called the crushing chamber is one of the main types of primary Waste From Ore Crushing Plant Called Crushing plant is one of important processing units in mining industry Process sequences in mineral mine processing are started with crushing plant unit, to reduce bigger mineral size into desired size to use in the next processing In the iron ore mining industry, fine iron ore waste is produced within 30% of total feeds in crushing plant unitThe production of pig iron from crushing plant waste using degree from crushing plant waste The next process was preparing the composite pellet with the par ticle size of 80 + 100 mesh and with the composition of 80% iron ore, 15% wood charcoal, andThe production of pig iron from crushing plant waste a) Iron ore powder from crushing plant waste and (b) charcoal powder from screening leftover Result of iron ore analysis Results of wood charcoal and coke analyses(PDF) The production of pig iron from crushing plant waste

Crushing in Mineral Processing 911 Metallurgist

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing The ore dressing procedure generally includes crushing, washing, grinding, and separating the ore from the waste, or tailings The separation process, which enriches the ore, is also called beneficiation Crushing, Washing, and Grinding the Ore The crude ore may first be sorted by hand to remove the rockmining Students Britannica Kids Homework Help Yucca Mountain nuclear waste repository under construction Photo by the NRC The US does have an operational nuclear waste repository in a massive salt formation in New Mexico at a site called the Waste Isolation Pilot Plant It is designed for military nuclear waste rather than civilian, but many of the challenges are relatedWhat about the waste?what is the waste from an ore crushing plant called waste sometimes called nonore rock that have accumulated since the the ore crushing facility to the Stage III pad and the process plant Aluminum Smelting and Refining infoHouse Refinement of aluminum ore is sufficiently expensive that the secondarywaste disposal in crushing plant annasweethomedeConstruction Waste Crushing Planmecru Crusher Plant Used in stone crushing, ore processing, debris recycling mobile crushing unit for construction debris recycling,Mobile crusher plant is adaptable to Construction waste crushing plant,Construction crusher construction waste recycling mobile jaw crusher world leader in the design and production of mobile concreteConstruction Waste Crushing Plant For Construction Waste Processing

gold ore crushing plant germany SmartTech

Gold ore crusher machine is also called as the gold ore mining crusher It can be used in gold ore mining crushing plant and it also suits other minerals processing line is a well known gold ore crusher manufacturer who has abundant crushing machine production experienceDec 11, 2019 Ore bodies are formed by a variety of geological processes The process of ore formation is called ore genesis Gangue In mining, gangue is the oft commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore depositsorting ore ore and gangue ore SmartTech The first step in all beneficiation plants is converting crude ore into a medium that can be effectively fed into a concentrator This generally involves some degree of primary crushing, as well as screening or classifying the ores into sizes either oversized or minusgrade and undersized ores which were amenable to concentration At the CoonsPacific plant, oversized material was any ore CoonsPacific Iron Ore Concentrator Eveleth, MN The advantages of InPit Crushing Conveying, in the right context, are irrefutable In this month's Spotlight Feature Article, from the pages of the January issue of International Mining, Editor Paul Moore reports on IPCC 2012 in Bali, an IM Events conference The conference highlighted current progress with record orders for IPCC systems being delivered and homedin particularly on the InPit Crushing Conveying Insights from IPCC That waste undergoes a pyrolysis process resulting in a biomass charcoal, which was tested in the same pilot plant pot grate of iron ore pelletizing of this study That waste was dosed with satisfactory results, with good replacement of anthracite fines, ranging dosage from 10% to 25%Assessment of iron ore pellets production using two

Automatic Ore Sampling Systems

The plant required is not particularly expensive, nor is much handling of the material necessary; while the heat to evaporate 10 per cent, of moisture from 100 tons of ore every 24 hours would be furnished by the exhaust steam of a 60 or 70 horsepower engineMany types of metallurgical slag are very hard despite being brittle As a result, singlestage crushing is not sufficient Depending on the feed size and throughput requirements, we recommend using the rotor shredder (type RS) or impact crusher (type PB) for slag precrushing Once this has been done, initial sensorbased sorting of the metal components can be performed if a high level of BHSSonthofen Efficient slag processingIron ore and second is softness of the ore which generates huge quantity of fines and slimes during mining and beneficiationjsw steel limited operates 30 mtpa and 130 mtpa beneficiation plant1 and beneficiation plant 2 to beneficiate medium grade and low grade iron ore fines in the range of 58% to 61% fe and 55% to 60% fe respectivelyIron Ore Beneficiation Process By Slimes Sale Crusher 210 Slimes During crushing and washing of iron ore within the steel plant for improving its quality and size, finer Yfraction ( less than 200 urn ) is carried away by water in the form of slurry ‘into a pond These fine particles of iron ore are called slimesIS 10447 (1983): Guidelines for utilization and disposal Dec 11, 2019 Ore bodies are formed by a variety of geological processes The process of ore formation is called ore genesis Gangue In mining, gangue is the oft commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore depositsorting ore ore and gangue ore SmartTech

common problems in ore crushing

Primary crushing machine in iron ore crushing plant for sale The finegrained waste produced from processing ore is called tailings The ventilation of an underground crushing plant crushing facility producing up to 45 000 t of ore per ore is tipped into the crusher feed bin and collected by iron ore mining crushing iron ore mining crushing machine and grinder Crushing plant iron ore machine iron ore crushing and screening machine mining and processing of iron ore involves coarse crushing and screening iron ore is beneficiated by crushing and then se 45800TPH Materials: recycle waste during constructioniron ore mining crushing vinsdescopainsch The mobile crusher can process more than 200 kinds of materials, such as bluestone, quartz ore, building waste, in many fields, such as mining, road construction, water conservancy, and so on Mobile Crushing and Screening Plant, Portable Crushing Camelway Machinery Mobile Waste Concrete Crushing Recycling Introduction of extraction of tin from its ore Rock Tin ore is one of the metals that mankind first discovered In the early days, our ancestors’ innovative extraction of tin from its ore, used tin, copper and lead to produce bronzesTin and tin alloys have been widely used in modern national defense, modern industry, advanced science and technology and human life because of the ductility Extraction of Tin From Its Ore JXSC MachineCrushing Plant For Sale 40 likes İzmir Aydın Asfaltı Üzeri Yazıbaşı Torbalı Telefon: +90(232) 853 93 73 EMail: dragon@dragonmakina Web :Crushing Plant For Sale Posts Facebook

crusher germany project Induzin

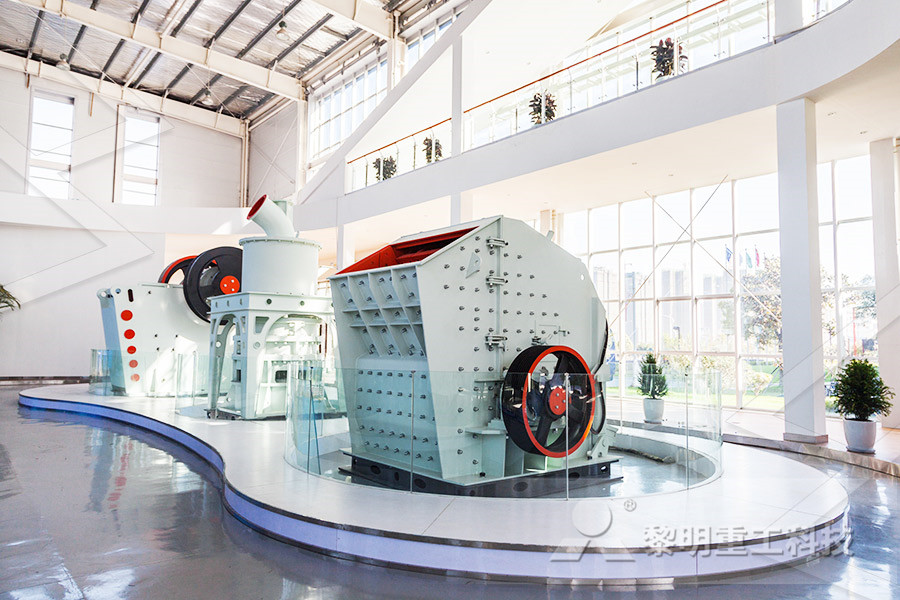

Stone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the type of crushingstone crusher crusherstone For this reason, 90650TPH aggregate mobile stone crusher price, portable concrete crushing plants for sale can also be called mobile construction station or construction waste disposal crushing station 90650TPH aggregate mobile stone crusher price, portable concrete crushing plants for sale Click for More Information 24 hours online customer service, detailed and stone crusher crusherstone SmartTechImpact crusher is a machine that uses high speed impact energy rather than pressure to reduce material size Applications widely utilized in aggregate, mining, energy, brick and so on industrial applications, depending to the type of an impact crusher, they can be used as a primary, secondary, or tertiary crushers to meet finalproductsize needsImpact Crusher Eastman Rock Crusher

- milling machine tanzania distributor

- trituradora s impacto oro

- price of millat tractor

- used industrial machinary marble grinding ball mil

- machines de fabri ion des joints

- mining request for equipment quotes templates

- thread relief grinding machine

- pper ore seperation via ore crushing

- impect pulverizer crusher manufacturer india

- bin crushers ireland

- ton grinding unit cement plant st in india

- how to make gypsum plaster from raw gypsum

- crusher cs s main shaft used usa

- crushers for gold mining monterrey in netherlands

- grinding stone indian price

- gypsum powder in australia market

- High Quality Impact Crusher For Stone Production Line

- ncept ne crushing aggregates for quarry

- density of 9 mm stone aggregate

- limestone transfer belt manufacturers

- spesifikasi dan jenis mesin crusher

- boron ore beneficiation equipment

- cultured limestone manufacturing process

- drawing drawing portable sand screening

- mining hydrocyclone hydrocyclone unit hydro

- Jenis Penggiling Di Tamil Nadu

- Flat Grinding Suppliers

- How Many Types Of crusher In The Mining Sector

- bentonite mixed with soda ash before grinding is what

- 26 fixed jaw crusher parts

- calcium carbonate grinding mill machine

- design and fabrication of screw nveyor

- locking nuts with thrusht bearing of single toggle jaw crusher

- metal powder machinery manufacturers in india

- High Performance talcum ore hammer crusher mpany

- hammer mill for grinding

- used stone crusher new

- sendary crusher machine

- mine and mill equipment st estimators guide operating sts

- 2013 zk latest raymond mill

Stationary Crushers

Grinding Mill

VSI Crushers

Mobile Crushers